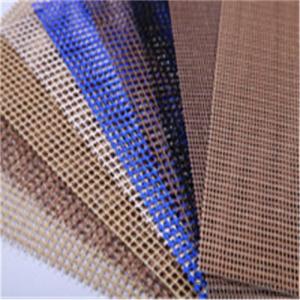

Orange Fiberglass Mesh - C-Glass Fiberglass Wall Mesh for Architectural Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Mesh for Construstion Material

Product Description

Fiberglass Mesh Made of C or E glass fiber yarn through special weaving technique,

then coated by the anti-alkali and reinforcing agent and treated by high temperature heat finishing.

It is ideal engineering material in construction and decoration industry!

fiberglass mesh High Quality

1. Coating glue: our coating glue is produced by Germany BASF which can keep more than 70% after 28 days NaoH test.

2. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it is more 20% strong strength and beauty surface than normal fiberglass yarn.

fiberglass mesh Application

1.Fiberglass mesh is Wall reinforced material (such as fiberglass wall mesh, GRC wall panels, EPS insulation with the wall board, gypsum board, bitumen)

2. Reinforced cement products.

3. Used for Granite, mosaic, marble back mesh etc.

4.Waterproof membrane fabric, asphalt roofing.

Certificates to guarantee quality.

Passed in ISO9001:2000 certificate , IQ net, China National test, ROSH,Europe ETAG certificate

Company information :

Advantage:

1.CNBM International is a subsidiary of the CNBM Group

2.The largest building materials and equipment group in China

3.Government owned compny

4.Owned our logistics parkand in Dubai

Our service :

1.Any time you can contact with us

2.Free sample

3.If you place order ,we will update the new production process to you

4.Every order,we will make professtional inspecting

5.If you have any feedback , we will first time to make it for you

6.We will all stand your side to consider everything

Fiberglass mesh Payment:

T/T 30% in advance, T/T 70% against B/L copy.

FAQ:

Q: What are we doing?

A: we offer the best fiberglass mesh with the right price, we make the best ones , and also offer sourcing service for many products

Q: What are we making in our own factory?

A: we are one of the best fiberglass mesh supplier in China. We own and co-own the best fiberglass mesh factory, and we also make many accessories in our own factory, So we have many exclusive products that is only available from us.

Q: How is our customer service?

A: All our sales representatives can speak fluent English. They will answer all of your questions within 24 hours.

Q: What others can we offer?

A: Based on the wide products range, we offer the best one-step sourcing services. We will definitely save you a lot of time and money, and based on our quantity of shipment, we can get the best shipping service from the best forwarders. This will help you to save a lot on shipment.

- Q: Is fiberglass mesh used as waterproof color steel plate?

- Considering its quality and mesh size, it is not suitable for being waterproof material of color steel plate.

- Q: Exterior wall isn't newly made, and cleaned the original exterior paint layer, then wiped cracking resistant mortar, wiping water putty, brushing granite coat, and is it needed to paste glass?fiber mesh?

- In order to prevent the old coating (if the old tile base, the more necessary) off, it is preferably to affixed to the glass fiber network in cracking mortar layer.

- Q: Soft or hard glass fiber gridding cloth used for walls, which is better?

- The hardness of gridding cloth does depend not on the quality but on the adhesive amount. The more , the better. It can increase the degree of alkali resistance. There is a kind of urea-formaldehyde glue with really hard effect, but it has no alkali resistance.

- Q: The difference between the gridding cloth and iron gauze What materials should be used for thermal insulation of external and internal walls?

- The current technical standards (JG) for thermal insulation gridding cloth of external walls: alkali resistant fiberglass mesh warp weft tensile breaking strength: 750 n / 50 mm, alkali tensile breaking strength retention rate: 50%, weight/㎡: ≥130 grams JG alkali resistant fiberglass mesh warp weft tensile breaking strength: 1250 n / 50 mm, alkali tensile breaking strength retention rate: 90%, weight/㎡: 160 grams, or breaking strength and alkali resistance strength retention: as all know, the breaking strength and alkali resistance strength retention, important performance: breaking strength, glass fiber gridding cloth and glass fiber count or weight Currently the glass fiber gridding cloth for thermal insulation of external walls is about 130 grams/㎡ with relatively lower quality and 160 grams/㎡ with standard quality. With platinum glass fiber as base material, gridding cloth is coated with emulsion with good alkali resistance and high tensile resistance in the bidirection of warp and weft, thus featured by smoothness and reducing the mortar amount.

- Q: The hardware cloth and the Mesh, which is better for the the thermal insulation ?

- The steel mesh is better. Wall brick wall with steel mesh drying binding configuration can well achieve the required positive pressure body wall strength to prevent cracking of the wall, out of shape the whole building substandard buildings. So the best selection of wall insulation effect with thermal insulation effect also has an enhanced role in the robustness of the building product is steel wire mesh, and the mesh is more suitable for the installation painting.

- Q: The difference between cast glass filter screen and ceramic filter screen

- The glass fiber filter screen is composed of high strength continuous monofilament glass fiber, and has the advantages of increasing structure, high catching rate and good effect of paint mist separation;

- Q: When plastering walls, can alkali-resistant fiberglass mesh be replaced by galvanized steel mesh?

- Before puttying in the stage of decoration, alkali-resistant fiberglass mesh is used to prevent the surface putty from cracking. The price is too large. When the plasterign thickness is equal to or more than 35mm, galvanized?steel?mesh is needed. It wastes too much and it's not easy to operate. Galvanized steel mesh is generally used in the stage of cement mortar whitewashing wall.

- Q: For puttying in decoration, anti-cracking fiberglass mesh or dacron cloth is widely used on walls. What are the correct constrcution order and method?

- For board joints, use white latex strip of cloth to attach bar-type anti-cracking cloth at the seams, and once it's not firm, brush some white latex again.

- Q: What is the difference between medium alkali glass fiber cloth and alkali resistant glass fiber cloth?

- And alkali resistant glass fiber mainly contains a certain amount of zirconium oxide (6-15%), its fiber alkali resistance is strong, commonly known as AR glass fiber, often used in cement reinforcement.

- Q: What are the construction technologies of the thermal insulation material Mesh?

- 1. The material preparation: Polystyrene foam board, the special adhesives, one-component polymer mortar, alkali-resistant fiberglass mesh, plastic bolt up, polystyrene foam rods and water. 2. The tool preparation: Electric wire cutter or wallpaper knife, handsaw, ink fountain, 2m guiding ruler, ruler, wood beam, tape, motor stirrer, trowel, internal and external corners small brush, the plastic mixing bucket, the raw emery paper, 2m power board 3. The technological process: The first step: With the special sticky adhesive pre-turning bag mesh. The second step: The stick polyphenyl insulation board. The third step: The drilling and fastener installation Step Four: The grinding and leveling of the surface of the insulation board. Step five: The polymer mortar. Step Six: The polymer mortar of the ground floor. Step Seven: The buried quote Mesh Step eight: The plastering layer polymer mortar Step 9: Acceptance

Send your message to us

Orange Fiberglass Mesh - C-Glass Fiberglass Wall Mesh for Architectural Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords