Oral Liquid Filling and Capping/Crimping Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

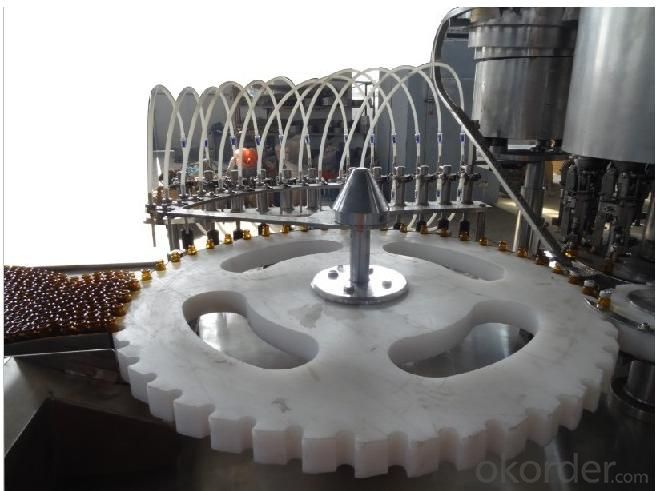

Oral Liquid Filling and Capping Machine

1. Detailed introduction

Oral liquid filling and capping machine, whole process include:automatic feeding oral liquid bottles, filling oral liquid, cap unscrambling, capping, outlet end products.

simple in structure, convenient operation, is the ideal multifunctional machine for oral liquid filling and crimping machine.

Can customized filling and capping heads accord to customers’ requirements.

All electrical parts adopting international famous brand, ensuring the stable, reliable and high precision.

Machine crack is made of dust-proof treated carbon steel, wrapped with SUS304 stainless steel. Food contacting parts made of SUS316 stainless steel.

no bottle no filling, automatic stopping as serious breakdown happened.

2. Technical parameter

item | Description | |

1 | KML-10D-6C series | 10filling heads, 6 capping heads |

2 | Filling volume | 10-20ml |

3 | Fill speed | 6000bottles/hour (the range for 10ml bottle) |

4 | Measurement precision | ±1% |

5 | Rated power | 1.5kw |

6 | Working air pressure | clean 0.55Mpa-0.65Mpa air |

7 | Net weight | 600kg |

8 | Contour Sizes | 1600×1500×1800mm |

Oral Liquid Filling and Criming Machine

1. Detailed introduction

Oral liquid filling and crimping machine, whole process include:automatic feeding oral liquid bottles, filling oral liquid, cap unscrambling, crimping, outlet end products.

simple in structure, convenient operation, is the ideal multifunctional machine for oral liquid filling and crimping machine.

Can customized filling and crimping heads accord to customers’ requirements.

All electrical parts adopting international famous brand, ensuring the stable, reliable and high precision.

Machine crack is made of dust-proof treated carbon steel, wrapped with SUS304 stainless steel. Food contacting parts made of SUS316 stainless steel.

no bottle no filling, automatic stopping as serious breakdown happened.

2. Technical parameter

item | Description | |

1 | KML-12D-8C series | 12filling heads, 8 crimping heads |

2 | Filling volume | 10-20ml |

3 | Fill speed | 8000bottles/hour (the range for 10ml bottle) |

4 | Measurement precision | ±1% |

5 | Rated power | 1.5kw |

6 | Working air pressure | clean 0.55Mpa-0.65Mpa air |

7 | Net weight | 650kg |

8 | Contour Sizes | 1800×1500×1800mm |

- Q: What is the design basis of automated packaging?! Just for today!

- Greatly improve the degree of automation of process flowA few years ago, automation technology accounted for only 30% of the design of packaging machinery, now has accounted for more than 50%, a large number of micro computer design and mechanical and electrical integration control. To improve the packaging machinery automation, one is to increase productivity; the two is to improve the flexibility and agility equipment; three is to improve the ability of packaging machinery to complete the complex action, namely the manipulator to complete the packaging process. Such as chocolate packaging has been achieved, with mechanical hand instead of the original manual. Automatic design of packaging machinery has the following two main characteristics:

- Q: The role of food packaging machinery

- 3) to achieve manual packaging can not achieve the operation, some packaging operations, such as vacuum packaging, inflatable packaging, body packing, isobaric filling, etc., are manual packaging can not be achieved, can only be achieved by mechanical packaging.(4) can reduce labor intensity, improve the working conditions of the labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease. Carton folding machine(5) in favor of labor protection for some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the cost of packing and save the storage and transportation expenses. It can reduce the volume and reduce the packing cost by compressing and packing the loose products, such as cotton, tobacco leaf, silk and hemp. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.(7) ensure product health of certain products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.

- Q: What is the price of a small jujube packing machine?

- What is the price of a small jujube packing machine?

- Q: What kind of reducer is commonly used in packaging machinery?

- Generally speaking, gear reducer, planetary gear reducer, and the most common one, these equipment power is relatively small, and some need to take the brakes of the motor reducer

- Q: What is the name of the paper used in packing machine parts and yellow?

- Rust preventive action, commonly used for steel vapor rust preventive paper, but also for a variety of metals.

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- You can send me a picture of your product and the process, so that I can answer your question exactly. More than 70% of the candies on the market are now automatically packed.

- Q: What's the fastest packing machine?

- Depending on the characteristics of your material, the speed is adjustable!

- Q: What are the packaging machines that use temperature control watches?

- A lot of heating machines have to use thermostat

- Q: What is a packaging machine?

- Well, before and after the associated processes, such as cleaning, stacking and disassembly. In addition, the package also includes the measurement or in the processes of stamp packages. Mechanical packaging products can improve productivity, reduce labor intensity

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

Oral Liquid Filling and Capping/Crimping Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords