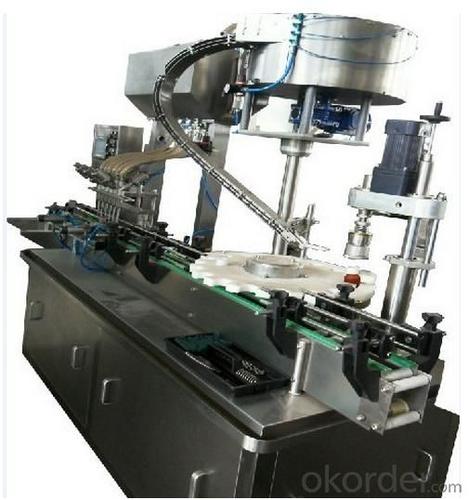

Liquid Filling,Plugging and Capping Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Liquid Filling, Plugging and Capping Machine

1. Detailed introduction

This machine with advanced design, intelligent structure, filling, inner stopper unscrambler, plugging inner stopper, outer caps unscrambler and capping integrated in one machine.it suitable round and other shape bottles.also can filling all kinds of liquid materials, such as syrup, sweetener etc.

No bottle,no filling,no bottle, no plugging, no bottle no capping,also could combine with other machines into a production line.

Adopt frequency control of motor speed, running speed continuous and adjustable.

Adopt high precision peristaltic pump filling, after filled, pump reversal and resorption driven by motor, ensure no drop, easy to dismantle, easy to clean.

Overload torque can adjust friction block type capping head, to prevent capping too loose or too tight, to prevent the cap surface wearing.

PLC control peristaltic pump to fill, touch screen operation, when adjust filling volume,just need to insert such filling volume, PLC will insert data ,automatically adjust filling, easy to adjust.

Machine crack is made of dust-proof treated carbon steel, wrapped with SUS304 stainless steel. Food contacting parts made of SUS316 stainless steel.

Real-time alarm----This filling machine can realize automatic alarming when the fault happens,automatic stopping and alarming when the system appears serious breakdown.

Protective door and configuration----Equipped with eco-friendly frame, realizing more clean and sanitary operation environment.

2. Technical parameter

item | Description | |

1 | KML-4D-2PC series | 4filling heads, 2plugging heads, 2 capping heads |

2 | Filling volume | 30-250ml |

3 | Fill speed | 2500bottles/hour (the range for 10ml bottle) |

4 | Measurement precision | ±1% |

5 | Rated power | 1.5kw |

6 | Working air pressure | clean 0.55Mpa-0.65Mpa air |

7 | Net weight | 650kg |

8 | Contour Sizes | 2200×1500×1800mm |

Liquid Filling and Capping Machine

1. Detailed introduction

Ø This machine with advanced design, intelligent structure, filling, outer caps unscrambler and capping integrated in one machine.it suitable round and other shape bottles.also can filling all kinds of liquid materials, such asfoodstuff, pharmacy, cosmetic, chemical and pesticide industries

Ø No bottle,no filling, no bottle no capping,also could combine with other machines into a production line.

Ø Adopt frequency control of motor speed, running speed continuous and adjustable.

Ø Overload torque can adjust friction block type capping head, to prevent capping too loose or too tight, to prevent the cap surface wearing.

Ø PLC control touch screen operation, when adjust filling volume,just need to insert such filling volume, PLC will insert data ,automatically adjust filling, easy to adjust.

Ø Machine crack is made of dust-proof treated carbon steel, wrapped with SUS304 stainless steel. Food contacting parts made of SUS316 stainless steel.

Ø Real-time alarm----This filling machine can realize automatic alarming when the fault happens,automatic stopping and alarming when the system appears serious breakdown.

Ø Protective door and configuration----Equipped with eco-friendly frame, realizing more clean and sanitary operation environment.

2. Technical parameter

item | Description | |

1 | KML-4D-1C series | 4filling heads, 1 capping head |

2 | Filling volume | 30-250ml |

3 | Fill speed | 2500bottles/hour (the range for 10ml bottle) |

4 | Measurement precision | ±1% |

5 | Rated power | 1.5kw |

6 | Working air pressure | clean 0.55Mpa-0.65Mpa air |

7 | Net weight | 650kg |

8 | Contour Sizes | 2200×1500×1800mm |

- Q: What is the general packing cost of beer beverage packaging?

- Beer beverage hot shrink packaging generally use PE heat shrinkable film, packaging temperature is usually in accordance with the film material and thickness to set,

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Sometimes, this wine packaging PigHead, with different types of vacuum packaging machine

- Q: The role of packaging equipment in packaging equipment

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging equipment is playing a more and more important role in the field of packaging. The main functions of packaging equipment are as follows:

- Q: What is the name of the paper used in packing machine parts and yellow?

- Rust preventive action, commonly used for steel vapor rust preventive paper, but also for a variety of metals.

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine packaging production, simple operation and high degree of automation, high efficiency, low packing cost, save labor, reduce the damage and the characteristics of two pollution, by tableware shrink packaging is widely used in all kinds of, is a very mature model

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;But to use the hot pressing machine there is to do bakelite mold. Our company specializing in the production of blister, in addition to help customers hot packaging, directly to the finished products to customers

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Graphic symbols for packaging and storageGB/T 5009.60. Analytical method for hygienic standard of polyethylene, polystyrene and polypropylene moldings for food packaging

- Q: Energy saving reform of packaging machine

- Due to the adoption of variable frequency speed regulation, the chain drive is greatly reduced, the stability and reliability of the operation of the machine are improved, and the noise of the machine operation is reduced. It guarantees the high efficiency, low loss and automatic detection of the packaging machine. It has both a beautiful and fashionable appearance, and a healthy and smart mind.Although the transmission system used in food packaging machine is relatively simple, it has higher requirements for the dynamic performance of the transmission. The system requires fast dynamic follow-up performance and high stability speed accuracy. Therefore, we must consider the dynamic technical indicators of inverters, and select high-performance inverter to meet the requirements.

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- English Name: Transparent, film, fold, wrapping, machineClassification: machinery, general machinery and equipment, >>J83 storage equipment, loading and unloading machineryICS classification: packing and conveying of goods, >>55.200 packaging machinery

Send your message to us

Liquid Filling,Plugging and Capping Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords