Scotch Packaging Tape Costco - Opp Adhesive Packing Tapes High Quality Colorful Printing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Width | 12mm,20mm,30mm,40mm,45mm etc.or as ur request |

| Length | As customer's require |

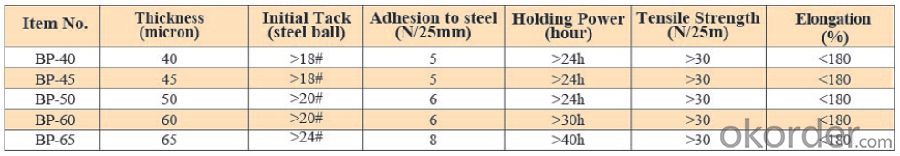

| Thickness | from35mic to 66mic |

| Adhesive | Acrylic |

| Color | Transparent, red, green, yellowish, brown, etc. |

| Packing | Shrink+carton boxes, container as ur request |

| Payment | L/C,T/T |

| Offer Printing | |

| Adhesive Type | Pressure Sensitive |

| Feature | Waterproof |

| Jumbo rolls Specification | 1280mm*4000m |

| 980mm*4000m | |

| 1610mm*6000m | |

| 1280mm*6000m |

Product Discription

Applications

Economical for general carton sealing

Auto-packing machine

Gift Wrapping & Decoration

Bundling &Strapping

Meet all kinds of transportation convenientl

Advantages:

OPP tape, superb tack and adhesion to surface

Strong grip that is ensured because of an excellent adhesive backing

Quality processing equipment that guarantees consistent quality

Peak performance even under extereme conditions of pressure and temperature

Sticks on all types of surfaces (paper, plastic, wood, glass, fiber and metal)

Consistent quality

On time delivery

Effective and timely communication

FAQ:

1. Q: Can I use our own designing?

A: Yes, size, color, printing, logo, paper core, carton box can be customized.

2. Q: What information should I prepare for a full quotation?

A: Size/ Thickness/ Color/ Printing/ Quantity/ Material.

3. Q: May I have samples?

A: Yes, free samples available and freight collect.

- Q: Is packaging tape easy to tear by hand?

- Yes, packaging tape is generally easy to tear by hand.

- Q: What are the advantages of using packaging tape over other sealing methods?

- Using packaging tape has numerous advantages compared to other sealing methods. Firstly, it provides a robust and secure seal capable of withstanding the challenges of shipping and handling. Its adhesive properties allow it to stick to various surfaces like cardboard, plastic, and metal, ensuring the package remains intact throughout its journey. Secondly, packaging tape is user-friendly and can be applied quickly to seal a package. Unlike glue or staples, it does not require any additional tools or equipment, saving time and enabling efficient packaging processes. Moreover, packaging tape offers versatility in terms of size and strength. It comes in different widths and thicknesses, allowing for customization according to the specific requirements of the package. Whether sealing a small envelope or a large box, there is a packaging tape option that suits your needs. Another advantage of packaging tape is its cost-effectiveness. It is generally more affordable compared to other sealing methods, making it an economical solution for businesses and individuals who frequently ship or package items. Furthermore, packaging tape is tamper-evident, adding an extra layer of security. Once applied, any attempt to tamper with the package will be apparent due to the broken or damaged tape seal. This serves as a deterrent against theft and offers peace of mind to both the sender and recipient. Lastly, packaging tape is easily removable without leaving any residue or damaging the packaging materials. This is particularly useful for packages that may require resealing or for recipients who may want to reuse the packaging. In conclusion, the advantages of using packaging tape include its strength, ease of use, versatility, cost-effectiveness, tamper-evident properties, and ease of removal. These benefits make packaging tape a reliable and efficient choice for sealing packages.

- Q: Is packaging tape safe to use on painted furniture?

- Packaging tape is generally safe for use on painted furniture, but it's important to consider a few factors beforehand. Firstly, make sure the furniture's paint is fully cured or dried, as tape on fresh paint can cause peeling. Additionally, check the type of paint used, as certain types may be more susceptible to damage or discoloration from adhesive tape. To be cautious, test the tape on a small, hidden area of the furniture to check for any damage. It's also advisable to remove the tape slowly and carefully to minimize the risk of harm.

- Q: Can packaging tape be used for sealing plastic storage bins?

- Yes, packaging tape can be used for sealing plastic storage bins. It provides a strong adhesive bond and helps secure the lids of the bins, keeping the contents safe and protected.

- Q: Can packaging tape be used for sealing medical supplies or equipment?

- No, packaging tape is not suitable for sealing medical supplies or equipment as it may not provide the necessary level of sterility and protection required in healthcare settings. Medical-grade adhesive tapes specifically designed for this purpose should be used instead.

- Q: How long does packaging tape last?

- The durability of packaging tape is heavily influenced by different factors including the tape's quality, the conditions it encounters, and its storage method. In general, packaging tape has the potential to endure for several months to a few years. Nevertheless, it is crucial to acknowledge that as time goes on, the adhesive qualities of the tape might start to diminish, resulting in a loss of its adhesive strength. Additionally, exposure to extreme temperatures, moisture, and sunlight can expedite the tape's decay. Hence, it is advisable to employ packaging tape within its recommended shelf life and keep it in a cool and dry area to guarantee its efficacy when required.

- Q: What is the average width of packaging tape?

- The average width of packaging tape typically ranges from 1.88 inches to 2 inches. This standard width allows for efficient sealing of boxes and packages, providing a secure and reliable closure. However, it is important to note that there are variations in tape widths available in the market, with some tapes being narrower or wider to accommodate specific packaging needs or preferences.

- Q: Does packaging tape have any specific certifications or standards?

- Yes, packaging tape can have specific certifications or standards. There are various organizations and standards that set guidelines for packaging materials, including packaging tape. One of the most common certifications for packaging tape is the International Organization for Standardization (ISO) certification. ISO sets standards for quality management systems, and packaging tape can be certified under ISO 9001:2015, which ensures that the product meets certain quality criteria. In addition to ISO certification, packaging tape can also adhere to specific industry standards such as ASTM International standards or European Union directives. ASTM International develops and publishes technical standards for a wide range of materials, including packaging tape. These standards ensure that the tape meets specific requirements related to strength, adhesion, and durability. Furthermore, some packaging tapes may have certifications related to their environmental impact. For example, certain tapes may be certified as recyclable, biodegradable, or made from sustainable materials. These certifications can be obtained from organizations like the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI), which promote responsible forestry practices. It is important to note that not all packaging tapes will have certifications or adhere to specific standards. However, if a packaging tape does have certifications or complies with certain standards, it signifies that the product meets certain quality, performance, or environmental criteria.

- Q: How do I cut packaging tape without scissors?

- In the absence of scissors, there are various alternative techniques that can be employed to cut packaging tape. One possibility entails utilizing a sharp knife or a utility knife, while ensuring utmost care is taken and fingers are kept away from the blade. Another approach involves employing a box cutter or a pocket knife, once again taking precautions to handle it safely. In case cutting tools are not accessible, one can attempt tearing the tape by firmly gripping it with both hands and swiftly pulling it apart. Nevertheless, it should be noted that this method might not consistently yield a clean cut. Additionally, resorting to using one's teeth to tear the tape is an option, although it is not advisable due to the potential risk of tooth damage or injury. It is crucial to always prioritize safety and exercise caution when employing any sharp objects for the purpose of cutting packaging tape.

- Q: What are the different adhesive options available for packaging tape?

- Packaging tape offers several adhesive options, each with its own distinct qualities and suitability for different uses. 1. Acrylic adhesive is commonly used in packaging tape due to its versatility. It adheres well to various surfaces and has excellent clarity, making it perfect for transparent or light-colored packaging. Additionally, acrylic adhesive forms a long-lasting bond and performs reliably in both hot and cold temperatures. 2. Hot melt adhesive is formulated for instant and strong bonding. It has a high initial tack and excellent holding power, making it ideal for heavy-duty applications or sealing boxes with rough or recycled surfaces. Moreover, hot melt adhesive withstands extreme temperatures and resists aging. 3. Natural rubber adhesive excels in adhesion to different surfaces, including recycled materials. Its high tackiness ensures a secure bond, even on challenging surfaces. Furthermore, natural rubber adhesive is resistant to UV light and aging, making it suitable for long-term storage or outdoor use. 4. Synthetic rubber adhesive, like natural rubber adhesive, provides strong adhesion to a wide range of surfaces. It offers good resistance to aging, moisture, and temperature changes, making it suitable for various packaging applications. 5. Solvent-based adhesive stands out for its high initial tack and excellent bonding strength. It quickly forms a bond, particularly on challenging surfaces like corrugated cardboard or recycled materials. However, it may emit strong odors and require extra safety precautions during use. When selecting an adhesive for packaging tape, it is crucial to consider factors such as the packaging material, surface conditions, environmental factors, and specific application requirements. Seeking guidance from adhesive manufacturers or suppliers can aid in determining the most suitable adhesive for your packaging needs.

Send your message to us

Scotch Packaging Tape Costco - Opp Adhesive Packing Tapes High Quality Colorful Printing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches