Office Furniture Commerical Desk/Table Solid Wood CMAX-BG141

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Office Furniture – Solid Wood Commercial Desk CMAX-BG141

Description of Office Furniture Commerical Desk/Table Solid Wood CMAX-BG141:

Type: | Office Furniture | Use: | Office Desk | Style: | Commercial Desk |

Material: | MDF/MFC, Melamine | Folding: | No | Color: | All Colors Available |

Volume: | 0.18 m³ | Customization: | Yes | Model: | CMAX-BG141 |

MOQ: | 20 Sets | Warranty: | 2 years | Use: | Commercial Furniture, office desk, office furniture |

We specialized in office desks and office seating. Our factory has been engaged in office furniture for more than 10 years and our factory is well-known for the high quality and competitive prices of our products. Our factory is well-known for the high quality and competitive prices of our products. We have won the praise of customers.

There are many types and colors to choose from. Our goods are easy and simple to handle and durable in use. Whether you need an office chair or modular furniture, we offer the service, experience and attention you deserve – no matter how big or small the job. Your satisfaction is our goal, that's why we only supply furniture from top brands! From workstations to cubicles, we have them all.

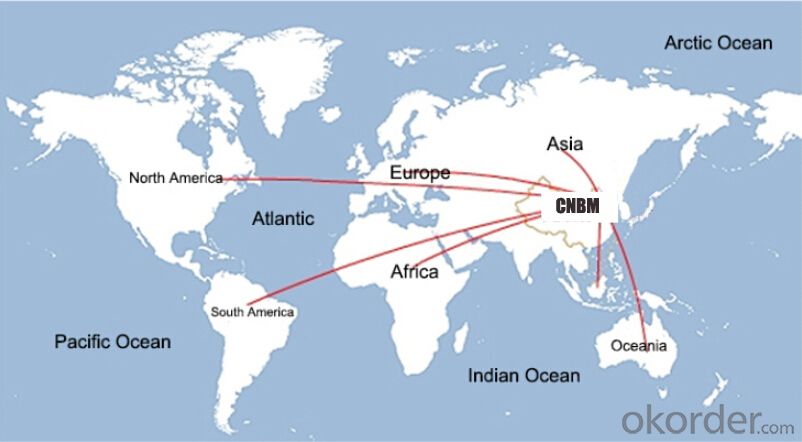

CNBM have a team of friendly and knowledgeable office Furniture and industrial furniture specialists who cater to our clientele looking for complete office fit outs.

We welcome any questions!

CMAX-BG141

1. Features of Office Furniture Commerical Desk/Table Solid Wood CMAX-BG141

1) Material: PU, PVC and fabric available

2) Height is adjustable

3) Rotation to 360°

4) Slide freely with wheels

5) Designs and patterns available upon request

6) Different colors are available

7) Elegant design, excellent workmanship

8) Height of seat and backrest adjustable

9) Seat pad thickness and backrest adequate

2. Quality Control

1) Each product is checked & cleaned before packaging

2) We do our best to resolve problems when they occur

3) Every step of production is carefully inspected by our professional QC team to ensure the quality of our products

Images of Office Furniture Commerical Desk/Table Solid Wood CMAX-BG141:

CMAX-BG642

2800*1225*1060

CMAX-BG141

2825*675*1125

CMAX-BG204

1450*2825*1125

CMAX-BG821

1500*2825*1050

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What about payment term?

A4: We accept 30%T/T in advance, with the balance before shipment. L/C at sight is also acceptable. Other payment term can be discussed with specific orders.

Q5: What is Melamine?

A5: Melamine is an organic compound that is often combined with formaldehyde to produce melamine resin, a synthetic polymer that is fire resistant and heat tolerant. The resin is a versatile material that has a highly stable structure. Its uses include whiteboards, floor tiles, kitchenware, fire retardant fabrics and commercial filters. Melamine can be easily molded while warm but will set into a fixed form, which makes it suitable for certain industrial applications. This compound is considered safe for normal uses.

Q6: What is MFC?

A6: MFC stands for ‘melamine faced chipboard’ and the vast majority of office furniture is manufactured with this material. There are a number of thicknesses used, but typically the industry standard is 25mm thick. Some budget ranges are 18mm thick. Essentially MFC is a picture (a photograph) of a real wood grain, repeatedly printed onto a Melamine film, and heat processed onto a sheet of chipboard. Most domestic furniture uses low density board, which is light. Most commercial grade furniture is made of a dense board – as it stops flexing and bending. MFC is available in a large number of plain colors and special finishes.

- Q: What kind of glue does plywood use now?

- According to the environmental protection grade, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and unqualified glue which can not reach E2 grade). E0 class is the highest environmental protection level. Plywood made of grade E1 glue can be used directly indoors.High quality urea formaldehyde adhesive / melamine adhesive / phenolic resin can be up to E0 and E1 grades, which can be used directly in the room.

- Q: How do electrophoresis plates do?

- 10 L DNA and 2 l sample volume bromophenol blue indicator sample buffer. The mixed sample buffer can not only improve the density of the sample, the sample is evenly sink to the sample hole, also can make samples with color, easy to sample and estimate and judge the position of electrophoresis electrophoresis time;8 use micro pipette to add sample carefully to sample hole, record sample order;9, cover the electrophoresis tank, turn on the power switch, the maximum voltage is not more than 5V/cm (100 ~ 150V constant voltage electrophoresis), so that DNA moves from the negative electrode to the positive electrode;Depending on the specific requirements of the 10 time with the electrophoresis experiment. Electrophoresis generally takes 1 to 3 hours. After electrophoresis power off, wearing disposable plastic gloves as far as possible to remove gel electrophoresis buffer with all stem, observed in the transmitted UV light of 254nm wavelength.

- Q: Which is the thickness of plywood and plywood?

- The first is correct, how thick is too thick, and the thickness below is positive and negative, not standard,For example, the correct one is "3MM", and the following is "2.7MM". The top is the standard thickness, and the following is the flux thickness,

- Q: What is the difference between building formwork and bamboo plywood?

- Toughness: the toughness of bamboo plywood is better;Number of times: ordinary bamboo plywood used 8 times, the building template in 6 times;Habits: the South with more building templates, the north with more bamboo plywood.

- Q: What kind of glue do you want to make the plywood?

- The cured urea formaldehyde resin is lighter in color and lighter in appearance than phenolic resin, and has weak acid and weak base, good insulation property, excellent abrasion resistance and low price, but it can be easily decomposed with strong acid and alkali, and has poor weather resistance. Trade name Beetle. 37% urea and formaldehyde in aqueous solution can be obtained by the polycondensation of linear urea formaldehyde oligomer in catalytic acid or alkali industry, with alkali as catalyst, reaction temperature of about 95, molar ratio of formaldehyde to urea is 1.5 ~ 2, to ensure that the resin can be cured

- Q: Which is better, bamboo plywood or wood plywood?

- Wood formwork is suitable for small high-rise buildings and is usually decided by engineering. You can understand each one has his good points, specific central arrows, they are specialized in the production of building template factory. Hope to be of help to you

- Q: How much is the wall of punched plywood one square metre?

- Light steel keel frame, plywood surface, single-sided 85 yuan / square, double-sided 115 yuan / square meter. Plywood is not suitable for partitions. One is the fear of water, water absorption will become uneven.

- Q: What is covered plywood?

- As the name suggests, the plywood is covered with film, and the resin coated board is mainly used for building and pouring cement. The film is difficult to bond with cement

- Q: What is bamboo plywood?

- Bamboo plywood is made of bamboo material as the main structure and filling material.

- Q: Will the ceiling be made of plywood or plasterboard?

- Plasterboard is good, plywood is easy to change, gesso board cannot make big modelling, big modelling uses medium density board

Send your message to us

Office Furniture Commerical Desk/Table Solid Wood CMAX-BG141

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords