OEM Aluminium Ceiling Panel Tiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1X20'FCL m²

- Supply Capability:

- 3000 M2 Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

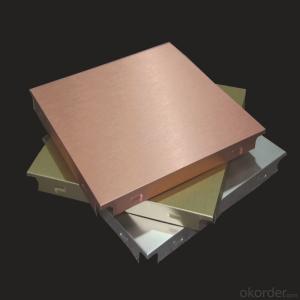

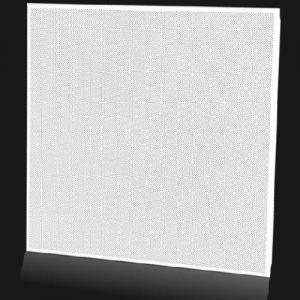

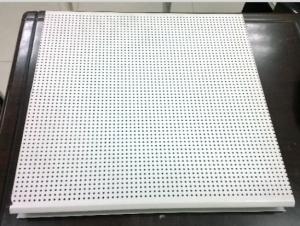

Specifications of Aluminum ceiling

1.Material: aluminium sheet

2.Size:600*600, 605*605, 100*100, 400*400, 500*500, 100*600, 150*150, 150*800

800*800, 300*300, 300*1200, 300*600, 600*1200

thickness from 0.45MM to 0.7MM

3.Colour: white,silver,any of the RAL colour,etc.

4.Edge:Lay in, Lay out and Clip in

Personality of Aluminum ceiling

1. tidy, clean and easy to clean and install

2.green and long time for qulity gurantee

Application of Aluminum ceiling

1.Fasle ceiling in Airport, Station, High-grade building

2.Washing room and kitchen etc.

Package of Aluminum Ceiling

1.Standard export package, film inside carton outside

2.16 or 20 pcs in one carton

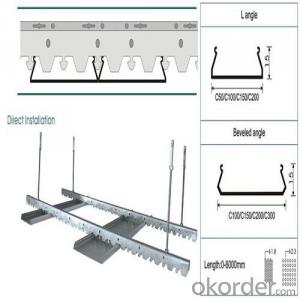

Installation instruction of Aluminum Ceiling

1. for square board

A.Firstly lift up the light keel and keep them at the same height and level

B:Enter the trangle card into the trangle keel, then according to the definite distance, put the triangle hanger into the light keel.

C:After finishing the installment of keel, press the clip-in square ceiling tiles into the slot of triangle keel(remark: the direction of folder with small hole is to insert into the slot of triangle keel)

D:Folding the edge which has no hole to connect the plate one by one, using the angle gap to install the plate and press a little on the plate, then it wil achive a better effect.

2.for c shaped strip ceiling

A:installing the wall angle at the same height

B:Arranging the hanging pole in a row and using hanger to connect the hanging pole with the keel, adjusting the height and flatness to the suitable position.

C:Pressing the two parallel edges into the triangle keel slot and making sure they are vertical mutually, then installing the rest plates.

D:Pressing a little on the plate when connecting the plates one by one, it will attain more better effect.

E:After the installment finished, then tear off the protective film covered on the aluminum plate.

F:Wearing gloves when installing plates, if you remain finerprint or stains on the plates, please remove it off with the boiled wter and detergent, and then dry it.

3.for curtain ceiling

A:As the open ceiling, it is necessary to brush the internal of the ceiling into back.

B:Fixing the expansion bolts into the ceiling then hanging the hooks or main keel onto the bolts

C.Put the curtain ceiling into the gap of the keels.

Production Line

We have 4 production line, 20 containers per month.

Our product combine quality with best price, there is a big professional team after the product.we are your best choice, we are waiting for your call.

- Q: What is the balcony ceiling hanging? Lycra board or sauna board? What kind of long life?

- See where you are hanging. The kitchen or the bathroom is the aluminum plate

- Q: Aluminum cords hanging ceiling, you can turn it?

- There is no problem, the integrated ceiling can do any!

- Q: How does the kitchen pick aluminum ceilings?

- Kitchen aluminum buckle ceiling is best to choose flat type. Kitchen smoke and more clean is a big project, you can choose nano-anti-fouling. Kitchen aluminum plate also pay attention to fire resistance and moisture resistance.

- Q: How the kitchen ceiling is blackened

- First shovel the original wall paint, and then re-scraping putty, putty scraping twice, sandpaper playing sand, and then paint. Dew paint the reasons there may be two: 1. The original bottom of the putty did not scratch, there may be cut corners; 2. Kitchen water vapor and hot air caused by changes in temperature. If the kitchen is high, it is recommended to make an aluminum slab ceiling, clean and convenient and durable.

- Q: Aluminum buckle board a side of the edge of how fixed

- Aluminum-plastic plate Construction process: keel layout and elastic line → installation and leveling keel → installation of aluminum-plastic plate → trim sealing. 1), the elastic line: to determine the elevation control line and keel layout line, if the ceiling has a variable height, the corresponding part of the variable section should be determined, and then along the elevation line fixed angle aluminum. 2), to determine the keel position line: According to the size of aluminum-plastic panels and ceiling Aluminum plate is made of aluminum alloy plate, through the open material, shear angle, molded, aluminum plate surface using a variety of different coating processing to get a variety of aluminum plate products, aluminum slab plate, the most important two Type, one is home improvement integrated Lvkou Ban, the other is the engineering Lvkou Ban, home-made aluminum slab board mainly to roll and frost the main series of two, with the development of home improvement integrated aluminum plate has been Variety of different processing technology are used to them, such as thermal transfer, glazed, ink printing, mirror, 3D and so on series is the most popular in recent years, home improvement integrated aluminum slab plate, home improvement integrated aluminum plate is Board surface fancy, service life, board advantage and so on to obtain market recognition, engineering aluminum slab board is commonly used roller coating, powder coating, film, scrub and other surface coating, the surface is relatively simple, the color is solid , Of which milky white is the most expensive to use aluminum slab plate, engineering aluminum plate to buy the most important depends on the coating, coating color protection is the primary consideration, the coating to maximize the life to ensure that the owners interest.

- Q: Metal ceilings, including aluminum slabs and so on

- Now gypsum board, mineral wool board is also constantly improving, there are waterproof gypsum board and sound-absorbing mineral wool board. But they are single plate, not easy to scrub, for the development of the keel keel, and more for the project. PVC products, poor oxidation resistance, no moisture, no fire, easy to deformation, discoloration, and more for the old ordinary home improvement. With the improvement of the quality requirements of the decoration, and now the home decoration has been basically used to do aluminum ceiling plate ceiling.

- Q: How to install the kitchen aluminum plate

- You have already installed the ceiling, you can first turn off the total power switch, and then connected to the line, then the lamp two buckle erected, aligned openings, until the raised buckle into the hole inside, and then The top of the lamp, the buckle will naturally stuck in the buckle plate, so that the installation of a successful.

- Q: How to distinguish between PVC plastic gussets and aluminum gussets?

- PVC plastic buckle plate and aluminum plate is the difference between the different materials, one is plastic, one is metal.

- Q: Aluminum cords hanging around the ceiling how to fight glass glue

- This seems to be no problem, aluminum slabs around the ceiling are generally close to the edge of the article, if your aluminum buckle plate is too thin and easy to deformation to cover the cover to cover defects.

- Q: The top of the kitchen did not line, like the largest reduction in space, at least how high Is the kitchen

- Then the general situation of such a ceiling distance of 800-1200cm Second, the kitchen, home kitchen, then the ceiling is generally between 300-500cm. Recommended at least not less than 20cm.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 9 Million |

| Main Markets | South America 8.82 Eastern Europe24.26 Africa 11.03 Mid East 45.75 Eastern Asia 10 |

| Company Certifications | CE CERTIFICATE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Foshan |

| Export Percentage | 80% - 90% |

| No.of Employees in Trade Department | 500-1000 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | 53,000 square meters |

| No. of Production Lines | 13 LINES |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

OEM Aluminium Ceiling Panel Tiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1X20'FCL m²

- Supply Capability:

- 3000 M2 Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords