Non-Woven Geotextile Fabric Mirafi PP Non-Woven Geotextile Industrial Nonwoven Fabric for Railway

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

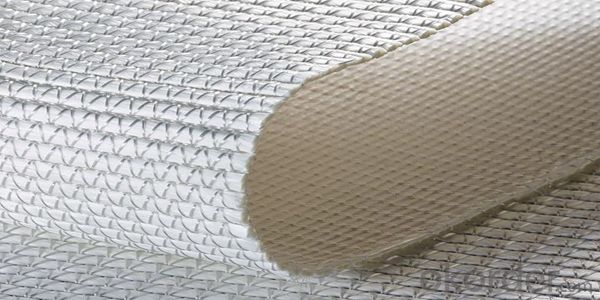

Non Woven Geotextile Introduction:

Nonwoven geotextiles are manufactured from the extrusion of polypropylene fibres which are then laid down on a manufacturing "bed" and then needle punched to entangle the fibres such that a dimensionally stable product is formed. Some additional thermal treatment is then applied to further improve the strength of the geotextile. Because of this manufacturing process non-woven geotextiles are generally best used in applications of drainage, filtration and protection

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles contribute to disaster management?

- Geotextiles contribute to disaster management by providing effective solutions for erosion control, slope stabilization, and flood control. These permeable fabrics help prevent soil erosion, reinforce unstable slopes, and retain sediments, reducing the impact of natural disasters such as landslides and floods. Geotextiles also assist in the construction of temporary roads and shelters, enabling easier access for rescue and relief operations during emergencies.

- Q: Design of interlocking turf slope protection brick directly on the geotextile, river earth side by 1: 2.5 slope excavation, began laying geotextile, grass sand and gravel, can lay it? Geotextile laying on the grassroots what are the requirements? More

- No special requirements, mainly from the role of filtering, over the water, but I, specializing in the production of geotextile, geomembrane, wish smooth

- Q: Are geotextiles suitable for use in underground drainage systems?

- Yes, geotextiles are suitable for use in underground drainage systems. Geotextiles are designed to provide filtration, separation, and reinforcement in various civil engineering applications, including drainage systems. They can help prevent soil and fine particles from clogging the drainage pipes, while allowing water to pass through freely. Geotextiles also enhance the overall performance and longevity of the drainage system by reducing soil movement and erosion.

- Q: Characteristics of nonwoven geotextiles

- Non-woven geotextile has many advantages: 1) air permeability 2) filterability 3) insulation 4) water absorption 5) waterproof 6) stretch 7) not disheveled 8) feel good, soft 9) light 10) Can be restored 11) without the direction of the fabric 12) compared with the textile production of high productivity, production speed 13) low prices, can be mass production and so on. Disadvantages are: 1) Compared with the textile fabric strength and durability is poor; 2) can not be washed as other fabrics; 3) fiber arranged in a certain direction, so easy to split from the right angle and so on. Therefore, the improvement of the production method has been mainly focused on preventing the improvement of the division.

- Q: How do geotextiles help with filtration in geosynthetic clay liners?

- Geotextiles help with filtration in geosynthetic clay liners by acting as a barrier to prevent the migration of fine particles while allowing water to pass through, thus enhancing the filtration efficiency and reducing the potential for clogging.

- Q: Application standard of filament geotextile

- National standard for filament geotextiles GB / T-1998 Geosynthetics Filament anti - sticking acupuncture non - woven geotextiles, the latest standard GB / T - 2008.

- Q: What are the specifications for geotextiles in landfill liner applications?

- The specifications for geotextiles in landfill liner applications typically include factors such as weight, thickness, puncture resistance, and permeability. The geotextiles used in landfill liners should have a high tensile strength to withstand the stress of the landfill waste, a thickness that provides sufficient barrier against punctures, and a permeability that allows for proper drainage of leachate. Additionally, they should meet certain industry standards and regulations to ensure their effectiveness in containing waste and protecting the environment.

- Q: What are the different geotextile manufacturing processes?

- There are several different geotextile manufacturing processes, including needle punching, thermal bonding, and weaving.

- Q: How do geotextiles help with load distribution in pavement systems?

- Geotextiles provide a reinforcing and stabilizing function in pavement systems by distributing applied loads more evenly across the underlying soil, reducing stress concentrations, and preventing the formation of cracks and deformations.

- Q: How do geotextiles help in soil stabilization?

- Geotextiles aid in soil stabilization by acting as a barrier, preventing the erosion of soil particles, improving soil structure, and providing reinforcement to the ground. They distribute loads evenly, reduce water flow velocity, and enhance soil filtration, thereby enhancing the stability and strength of the soil.

Send your message to us

Non-Woven Geotextile Fabric Mirafi PP Non-Woven Geotextile Industrial Nonwoven Fabric for Railway

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords