Non Woven Black Geotextiles Factory Supply 200g/m2 for Earthwork

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 30000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of our Geotextile:

- Factory directly supply

- Polyethylene Terephthalate

- Polypropylene

- ISO9001/ 14001

- Material:PP/PET;Weight:100g-1500g/m2 ;Roll width:1m-8m/roll

Gextextile Product Description:

--Our geotextile can be made of polypropylene (PP) or polyester (PET) .

-- The weight is available from 100g/m2 to 1500g/m2 and the width from 1m to 8m,

-- Two kinds of processing technical to select: needle punched and thermally bonded, long fiber or short fiber.

-- All kinds of colors are available.

-- It is widely known as earthwork material and industry fabric, used in the areas of railway, highway, water conservancy, dam, tunnel, subway, environment protection and so on.

-- We can supply different specifications as customers’ request.

Geotextile Product Specification / Models:

Material: polypropylene (PP) thermally bounded

Weight: 100g/m2-1200g/m2

Width: 1-8m

Length: As customers’ demand (usually is 100m)

Package: PE film and woven cloth

Delivery time: With in 3weeks after received the advance payment

Payment terms: T/T 30% in advance+T/T 70% against the copies of original documents or L/C

PS. Also we can produce the product as customer’s demand.

Application of Geoxtile:

1. Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2. Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3. Reinforcement

The highway, railway, soilstone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4. Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Technical specification of short fiber needle punched non-woven geotextiles:

According to GB/T17638-1998 Standard

No. | Item | Specification | Note | ||||||||||

Mass per square meter g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | ||

1 | Weight Variation % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

2 | Thickness mm ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width Variation % | -0.5 | |||||||||||

4 | Breaking Strength KN/m | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD and CD |

5 | Elongation at Break % | 25 ~ 100 | |||||||||||

6 | CBR Mullen Burst Strength KN≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

7 | Sieve Size 090 mm | 0.07 ~ 0.20 | |||||||||||

8 | Vertical Permeability Coefficient cm/s | k× (10-1 ~ 10-3) | k=1.0-9.9 | ||||||||||

9 | Tear Strength KN ≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD and CD |

Needle punched geotextile after treatment method | |||||||||||||

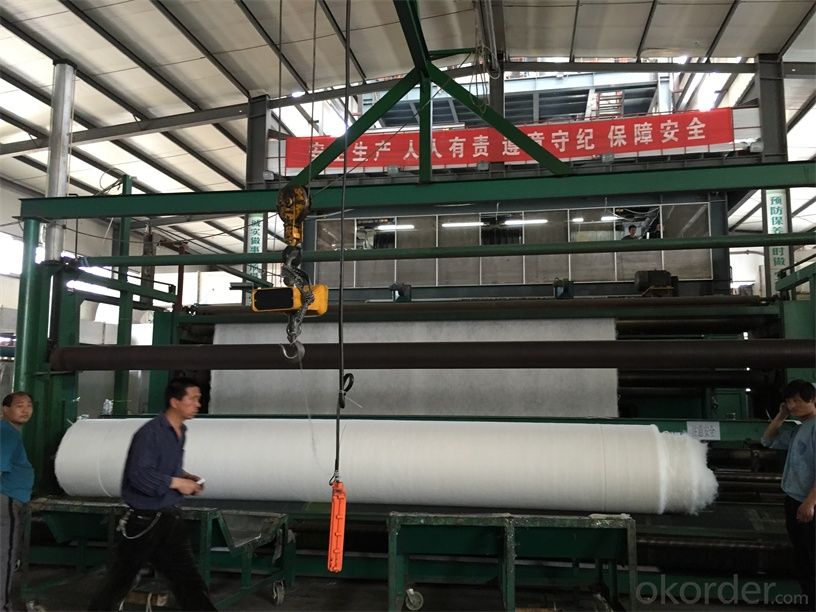

Geotextile Products Show:

FAQ of our geotextile:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: How can TR fabrics and TC fabrics be distinguished?

- When the pet is not less than 50%, stable size, strong anti wrinkle, the fabric can keep a pet, wash and wear characteristics can be strong. The mixing of viscose fiber improves the air permeability of fabrics, improves the resistance to porosity, reduces the pilling and antistatic properties of fabrics.

- Q: Who can tell me what kind of fabric peach is?!

- The formation of the unique style of peach skin fabric is the basis of super fine, high density and thin fabric, and the grinding finishing is the key of the product.The main factors influencing the effect of cashmere fabric with sandpaper grinding: the choice of mesh control roller speed, grinding roller contact area with the fabric, fabric tension, sanding times, roller speed and speed balance, moisture fabric, sanding after processing and sanding equipment selection etc..Peach skin products can be used as clothing (jackets, dresses, etc.) fabrics, but also as boxes, shoes and hats, furniture and decoration of the ideal material

- Q: What do you mean by four piece cotton fabric 128*68 cotton?

- Pure cotton represents material. This is very simple128*64 you can understand that the density of fabrics, called weaving, is generally marked by "XX*XX weave"The higher the fabric is said to do more thin, and the material process requirements higher, of course, the cost is higher. They sell expensive.

- Q: What is a composite fabric?

- Composite fabric is a kind of superfine fiber used in special textile processing and unique dyeing and finishing, and then processed by compound equipment. Application of composite fabric "high technology and new materials of new synthetic fiber", with many excellent properties (compared with ordinary synthetic fiber), such as fabric performance, fine clean delicate, elegant, warm, fabric appearance plump, windproof, breathable, waterproof function, fabric warm and good.

- Q: Will mulberry silk shrink if it is washed?

- Silk material shrinks.However, before generally do clothes are made with shrink, so most buy garments are not shrink, unless you buy a silk cloth for tailor, it must first put the cloth over the water to make clothes, generally not shrink too much.Between the silk fabric fiber mutual consolidation is not strong, so it is relatively easy to shrink, so the general silk fabrics in clothing made will be washed again, but in order to prevent the event, a large number of recommendations should be selected in the purchase when the silk clothing.

- Q: What's the fabric of Odair?

- I was doing the children's clothing, more clearly, is a kind of new environmentally friendly fabrics, very high-end products of cotton, absolutely not downstairs said modal, modal and Odair is completely two concepts, modal is cotton polyester blended.

- Q: What is lace? What is the material of lace?

- Lace is a kind of exotic. Mesh tissue, originally Crocheted by hand knitting. The lace fabric is light and transparent because of its material quality, and has elegant and mysterious artistic effects. It is widely used in women's clothing.

- Q: Shirt fabric. What material is good?

- The most popular blends are 65% polyester and 35% cotton, which are not only very comfortable but also look very cheap. If you decide to buy blends, you should buy Fabrics with at least 50% of the cotton fabric. Generally speaking, the more cotton in the blend, the more gorgeous the shirt looks.The shirts are ideal for light, thin, soft, cool, clean and breathable, and can be divided into a wide variety of fabrics.

- Q: What cloth is Rome cloth? What are the characteristics?

- Rome cloth is four road a cycle, no ordinary cloth double-sided cloth, a bar is not too slight rules.

- Q: What's the difference between fabric and lining?

- As one of the three elements of clothing, fabric can not only interpret the style and characteristics of clothing, but also directly influence the color and shape of clothing.

Send your message to us

Non Woven Black Geotextiles Factory Supply 200g/m2 for Earthwork

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 30000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords