PET Spunbond Filter Nonowven Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 15 container per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

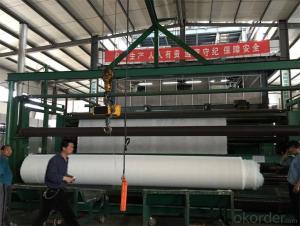

PET Spunbond Filter Nonwoven Fabric

Specification of PET spunbond filter nonwoven fabric

Material:100% PET filament

Weight:15-250gsm

Width: 10-320cm

Length:100-2500m

Techinque: spunbond

Pattern:plain,diamond

Application of PET spunbond filter nonwoven fabric

It is characterized by high filtration efficiency, high tensile strength, acid alkali –resistance, mothproofing and poisonlessness. Widely used as filtration material, fold filter cartridge and filter core. It was widely used in air filter, dust filter, liquid filter etc.

The product has passed the SGS certification.

- Q: Expert: waterproof zipper how to fit together with bags and fabrics?

- Methods using high frequency voltage and the waterproof zipper bags fabrics fit together, bags fabrics must use rubber soled to voltage.

- Q: Excuse me, containing 100% Tencel fabric clothes Tencel OK? What is it?

- Tencel is a cellulose fiber, using solvent spinning technology, dry strength is slightly lower than that of polyester, but significantly higher than the viscose fiber, viscose wet ratio has improved significantly, with very high rigidity, good dimensional stability washing (only 2% shrinkage), moisture absorption is higher. The fiber cross-section is round or oval, shiny and beautiful, soft hand feeling, good drapability, elegant and good. To sum up: warm and soft Tencel with 1 cotton 2 polyester high tenacity 3 hairy in hot and humid conditions but it is easy to harden, pick down in cold water is not good.1, high dry strength and wet.

- Q: What is the sanding fabric

- Sanding is a kind of technology in the textile industry, cloth by friction sanding machine and diamond rubber, which has formed a layer with downy feeling fabric surface, not only retains the original characteristics and gives the fabric a new style, adding warmth and softness, thick soft texture, rich, have the characteristics of the color does not fade, no pilling timeless, suitable for winter warmth products and personal use.

- Q: What's the fabric of Odair?

- Odair is a plant fiber protein 95% +5% cotton spandex, cotton spandex +5% 95% there are many on the market, but it can't be called Odair, is the general spandex industrial synthesis, so only with elastic, not smooth, silky breathable feeling, Odair cotton must be prepared and refined cotton plant fiber textile.

- Q: What kind of clothes do you wear cool in summer?!

- Generally speaking, silk, cotton, linen and other natural fibers are the best summer clothing materials. Among them, the silky silk has the best skin affinity, high-grade clothes are made of silk, both comfortable and beautiful.Cotton, hemp in terms of quality, there are many levels, their sources of raw materials even if the same, different yarn twist, weave different, can affect the texture of clothes.

- Q: Is dacron cloth waterproof?

- The polyester fabric itself is waterproof, but if used for waterproofing, a PU coating is required because the PU coating blocks the fabric's pores.

- Q: Pretty broad. What does it mean?

- Crisp meaning is simply to stand, then look smooth, make clothes protection effect is good, not limp!Fabric is the material used to make clothes. As one of the three elements of clothing, fabric can not only interpret the style and characteristics of clothing, but also directly influence the color and shape of clothing.

- Q: In addition to pure cotton, what fabrics do not have static electricity?

- Because water is a conductive material, so the fabric is not easy with static electricity, but if the moisture in natural materials (such as polyester fiber (polyester only 0.4%)) into easily conductive material, the fabric is not easy with static electricity, this material is added to the conductive wire, a wire, a plus carbon fiber. This kind of fabric is a kind of antistatic fabric.

- Q: What's the reason for Pilling?

- The washing time is too long, which will cause the fiber to be damaged, break the fiber and produce more fiber ends, thus increasing the possibility of pilling.

- Q: What fabric can be sand washed?

- Sand washing is divided into light, medium, heavy wash three, heavy clothing after washing is obvious in hand, raised surface effect, especially as the heavy silk crepe de Chine, spun silk and satin, after heavy, feel soft, creamy texture, good hanging. But the fastness of the fabric washing sand, generally suitable for thick fabric. The sand washed silk clothing, its price can be increased by more than 5% at least.

1. Manufacturer Overview

| Location | Zhejiang,China |

| Year Established | |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East,Europe,The America,Southeast Asia Africa ,Oceania ,Mid East |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Ningbo,Shanghai |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 15 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above200,000 square meters |

| No. of Production Lines | 20 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

PET Spunbond Filter Nonowven Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 15 container per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches