MZ001-7 screw microsprayer with aluminum collar

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product decription

1.Item: MZ-001-7

2.Material: plastic+aluminium

3.Diameter:24mm

4.MOQ: 10, 000pcs

5.Packing: inner + outer package

6.Carton Size: 57*33*39cm Pcs/Ctn: 2400pcs

7.Delivery date: 20-30days

8.Payment Term: T/T by 30% deposit and balance before shipment or against by B/L copy.

Product show

Advantage

The Advantage of our lotion pump:

1) For the first using 2.5-3 times of pushing will workable

2) Many improving leakproof design for guarantee

3) Glass ball which resistant to acid and alkali

4) Non-Toxic pump meeting international standard requirements

5) Accept small order

6) High quality, nice price.

7).Colour depend on customer's request

8).Using innocuity imported raw material, high stability

9).High quality, Best service, Low price

10).Lotion pump is applied on the bottles of facial cleanser, hand cream,lotion and so on.

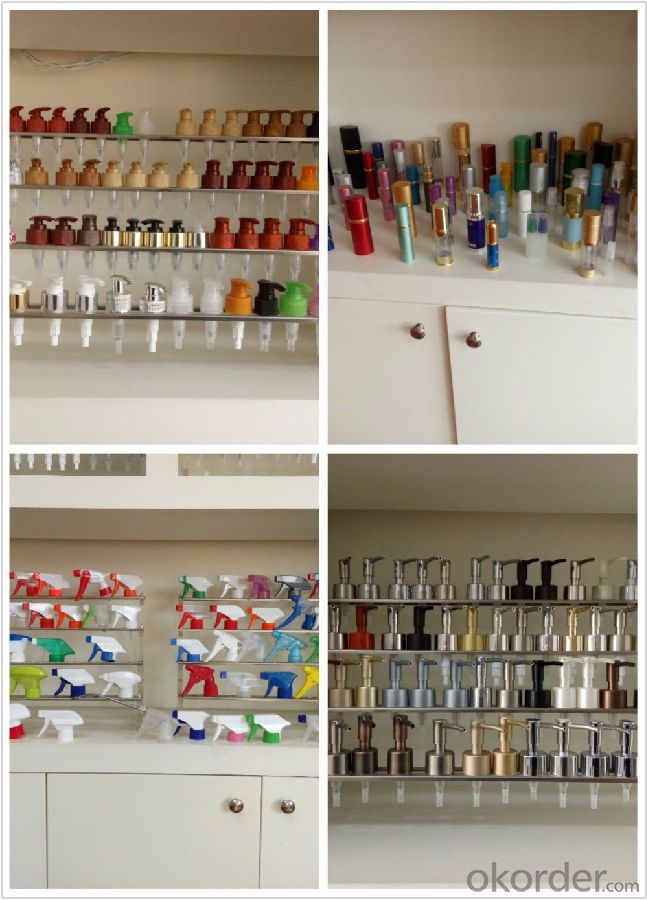

Sample room

- Q: There's no trick about the bottle top

- Turn the bottle down into the water. You see, the water in the pot has just passed the bottle cap, and you can start the bottle in about half a minute.Let me tell you this time. Why does this method open the bottle top?,This is because the object has the characteristics of thermal expansion and cold contraction, and the metal cap is exposed to hot water and expands rapidly,Although the glass bottle will swell when heated, it is a step closer and is heated through the bottle cap.

- Q: Why do I drink water and leave the bottle top and can't drink?

- That's not enough. You'll get tired of drinking too many bottles.

- Q: The lid of the refrigerator in the mini - fridge is gone. Is that ok?

- The refrigerator in your house has no cover, so it will affect the refrigerator!1, this compressor does not stop, it is very expensive.Cut 2, refrigerator, the performance is more and more bad.

- Q: Want to use bottled beer brewed Wine, can not choose who can give good cap to think of a way?

- Buy some cap like cans, glass bottles that chant, the market has

- Q: What is the reason for the loose sealing of the bayonet aluminum cap?

- Pressure sealing plugPressed into the bottle stopper, by its own elastic deformation method composed of bottle tightly sealed, known as pressure sealing plug (Fig. 11-1c) made of cork. Cork, commonly used rubber and plastic material that has certain elasticity, its structure and shapes, figure 11-2 shows the common shape.

- Q: How do I open the wine bottle without a bottle opener?

- 1, find a hook or thin steel wire.2. Adjust the angle of the hook or wire with pliers.3. Extend the hook from one side of the cork to the bottle, rotate the hook and hook the cork and pull it out.Note: it is best to wear a pair of gloves so as not to hook or scratch your fingers.

- Q: In a big glass bottle to bottle sparkling, seals do not leak?

- Originally the best seal is used with the original glass bottle with plug cap (frosted glass cover). But now the complete set of glass bottles frosted quality is too bad, sealing is not very good.

- Q: How many pleats are there in all beer caps? Why?

- This standard not only defines the diameter of the bottleneck, but also the shape of the edge of the bottle cap and the manufacturing material.

- Q: How are plastic caps made?

- The plastic pressing cover production process is:The mixed material into the pressure machine barrel suction machine, heating to a semi molten state in the plasticizing barrel after quantitative extrusion to the mold cavity, the upper and lower mold mold, plastic pressure and cooling, demoulding, after cutting ring, plus pad, complete the production of pressure plastic cover. Compare:The injection cover needs to be heated to a molten material flow, temperature at 250 degrees Celsius; plastic pressure only needs to be heated to 180 DEG C, the ratio of energy consumption high pressure injection molding cover;The moulding of low temperature, little shrinkage, cap size accurately;The injection of a fill all cavities, each time a bottle extrusion pressure plastic materials. Press extrusion pressure is very small, and injection molding needs high pressure;The injection molding of large volume, single cavity replacement trouble; plastic pressure for each cavity is relatively independent and can be replaced individually;The plastic bottle cover, pressing machine is a special machine, specifically for the design of bottle cap mold; injection molding machine not specifically designed to cap, so the pressure plastic cover can be made of horn, hanging cover rate is high, users love to use.

- Q: How to build the lid of a pressure cooker?

- The lid of the pot does not rotate.Reason:There may be a safety device (check valve) at work. There is a hole in the lid handle, there is a safety device, a pot of pressure and to a certain extent when the bumper from the top, then you are not screwed the lid, and the pressure to a certain extent, the bumper fall, then to screw the lid.

Send your message to us

MZ001-7 screw microsprayer with aluminum collar

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords