Multi-layer Aluminum Foil with Plastic Film Used For Packing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 1000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

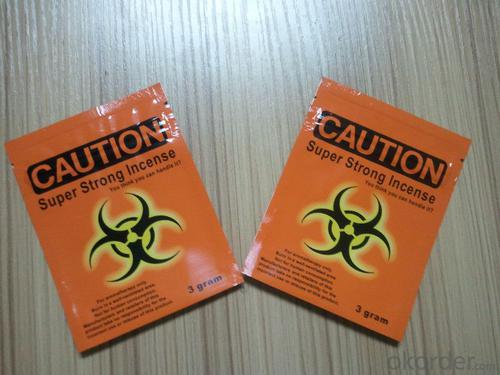

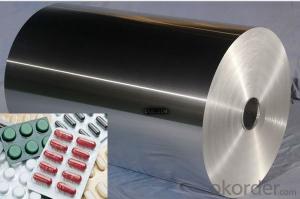

1. Description of Multi-layer Aluminum Foil with Plastic Film Used For Packing:

Multi-layer Aluminum Foil with Plastic Film Used For Packing are processing with imported materials, we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Multi-layer Aluminum Foil with Plastic Film Used For Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Of Multi-layer Aluminum Foil with Plastic Film Used For Packing:

Excellent quality control

Experienced factory produced

SGS passed

3. Multi-layer Aluminum Foil with Plastic Film Used For Packing Photos:

4. Multi-layer Aluminum Foil with Plastic Film Used For Packing Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Multi-layer Aluminum Foil with Plastic Film Used For Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Express carton packaging, plastic packaging should be how to deal with?

- For those cartons, environmentalists have their own ways of using them. "The Jingdong loves to use plastic bags, and Amazon and its customers prefer cartons."." Some of the more orderly carton, you can keep as a storage box. You can use the marker pen to write the contents on the carton, then stack it on the bottom of the cupboard to improve the space utilization. For some cartons that cannot be used for the time being, use the tape on the carton to flatten the cartons.

- Q: How do I remove the self-adhesive label affixed to the plastic bag?

- With the label supplies into the water immersion, after the label has been soaked, erase. This method is also applicable to metal and plastic tools, but it takes time.

- Q: What are the requirements of the mark on the cement packing bag?

- The cement packing bags shall clearly indicate the standards of implementation, cement varieties, codes, strength levels, producers' names, production licence marks (QS) and serial numbers, serial numbers, date of packing and net contents. Bags on both sides should be based on the varieties of cement with different color printing name and cement strength grade, Portland cement and ordinary portland cement Portland slag cement by using red, blue gray volcano; Portland cement and Portland fly-ash composite silicate cement by sleep and black or blue..

- Q: What are the advantages and disadvantages of OPP and CPP membranes? What kind of bags are they used for?

- (feature film, also called special film) potential uses include: food packaging, candy packaging (twisted film), drug packaging (infusion bag), on the album, folders and files and other fields instead of PVC, synthetic paper, adhesive tape, name card holder, ring folder and composite bag stand.

- Q: What about the use of plastic bags?

- Now all walks of life have the use of plastic packaging bags, only grades, such as the food market is the worst, supermarkets in general, and then to food packaging non-toxic environmentally friendly plastic bags.

- Q: How much is the 1 wire in the food packing bag printing industry?

- Now the standard of living has improved, basically the food package. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: What are the packaging forms of fresh milk?

- The main packaging forms of fresh milk are plastic bags, boxes and bottles. It is closely related to the way of sterilization of fresh milk

- Q: How big is the vacuum pack 28*40cm?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: Is there any identification on the vacuum package?

- Continue ink jet printer (continuous spraying machine), referred to as CIJ inkjet printer. The principle of operation is that the ink is ejected continuously through a single nozzle and is broken by crystal oscillation to form ink dots. After the ink point is charged and deflected at high pressure, the ink is scanned on the surface of the moving object. Such as Domino A100.

- Q: What's bread packing? Polyethylene film, waterproof cellophane, etc.

- Currently, about 90% of the bags are packed in polythene plastic bags.

Send your message to us

Multi-layer Aluminum Foil with Plastic Film Used For Packing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 1000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords