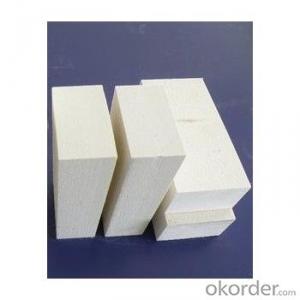

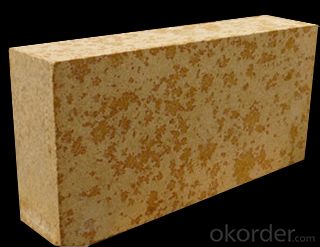

Mullite Brick - Low Apparent Porosity Insulating Fire Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Details: | Wood carton box:10pcs/carton wooden pallet:544pcs/pallet |

Delivery Detail: | 15 Days deposit |

manufacture low apparent porosity mullite insulating fire brick for heating furnace

Product Description

Low apparent porosity mullite insulating fire brick for heating furnace is a kind of insulation refractory product taking mullite as main raw materials.It enjoys high temperature resistance, high strength, nd low thermal conductivity. Besides, it can directly contact the flame, and can be used in lining of a variety of industrial furnaces.

key features

1.Low density High purity

2.Low iron Low thermal conductivity

3.Excellent thermal shock resistance

application

1.Glass industries iron & steel industries

2.Ceramics industries non-ferrous metals industries

3.Electrolytic Aluminum industries power generation industries

4.Heat surface fireproof lining other fire-proof back lining

Technical Data

Index of refractory Mullite lightweight brick | ||||||

item | AL2O3% | Fe2O3% | Bulk Density, | Cold Crushing | linear change | Thermal conductivity |

g/cm3 | Strength Mpa | on reheating/% | /W.(m.k)-1(350℃) | |||

P30-6 | ≥52 | ≤1.0 | <0.6< p=""> | ≥1.5 | ≤1.0(1350°C,12h) | 0.2 |

P40-8 | ≥55 | ≤0.8 | <0.8< p=""> | ≥2.5 | ≤1.0(1400°C,12h) | 0.28 |

P50-10 | ≥60 | ≤0.8 | <1.0< p=""> | ≥4.0 | ≤1.0(1500°C,12h) | 0.33 |

P60-12 | ≥72 | ≤0.8 | <1.2< p=""> | ≥2.5(1.2) | ≤1.0(1650°C,12h) | 0.44 |

P60-135 | ≥72 | ≤0.8 | <1.35< p=""> | ≥3.5(1.4) | ≤1.0(1650°C,12h) | 0.48 |

P65-155 | ≥76 | ≤0.8 | <1.55< p=""> | ≥3.8(1.6) | ≤1.0(1650°C,12h) | 0.53 |

P70-165 | ≥80 | ≤0.6 | <1.65< p=""> | ≥6.0(2.8) | ≤1.0(1700°C,12h) | 0.7 |

P80-175 | ≥85 | ≤0.5 | <1.75< p=""> | ≥6.0(2.8) | ≤1.0(1750°C,12h) | 0.72 |

other products

- Q: Aluminum content 38, silicon content 55 What refractory bricks?

- Semisilica brick: the content of Al2O3 is 15% ~ 30% of aluminium silicate refractory products. Manufacturing products are semi silica quartz containing impurities or native clay kaolin, refractory clay or kaolin beneficiation tailings and the pyrophyllite

- Q: (refractory castable, silicon carbide brick, mullite bricks etc.) do testing should be commissioned by the project? What are the specific qualification standards? Thank you

- Different refractory materials have different requirements, specific industry or national standards, such as LZ can check the mullite bricks GB / standard, there should be a harvest, do testing project is in accordance with the requirements of the LZ need to determine the use requirements

- Q: What are the properties of corundum mullite?

- Lightweight materials have uniform internal structure, high compressive strength, corrosion resistance, heat shock resistance, oxidation resistance, high temperature and low thermal conductivity.

- Q: What is the difference between mullite ceramics and alumina ceramics? Can you tell me something to do with floor tiles?

- Corrosion resistance: mullite acid is not alkali resistant. Alpha alumina ceramic acid, alkali resistance - for floor tiles, alumina corrosion resistance is too high, unnecessary.Sintering temperature: the sintering temperature of mullite is low. So the cost is low because of this, so alumina ceramic is basically not used for floor tiles - unless it's too rich to burn.Heat shock resistance: the thermal shock resistance of mullite is higher than that of alumina.High temperature creep properties: the high temperature creep of mullite is higher than that of alumina, so mullite can bear higher weight at high temperature, and alumina is less.Resistance: alumina ceramic resistor is higher than mullite, so it is used as high-voltage insulators.

- Q: What is the price of refractory bricks?

- The refractory insulating brick generally refers to light brick, normal furnace lining are using this brick kiln will not increase the weight, and good heat insulation effect and ordinary insulating brick production are made of clay, high alumina high strength low iron bead brick, mullite, high aluminum light insulating firebrick, diatomite insulating refractory brick, the use of light heat insulation brick can increase the use of space, and good insulation effect

- Q: Jm26 mullite aluminum content in the number, ask God to answer. 23 more. How is this identified with the naked eye?

- In the presence of excess EDTA in the acidic medium, the aluminum is complexed with EDTA, and the remaining EDTA is complexed with lead salt, and then the EDTA complexed with aluminum is replaced by sodium fluoride, and the lead salt is substituted...

- Q: Mullite brick

- High refractoriness, up to 1790 degrees celsius. The softening start temperature is 1600~1700 degrees. The compressive strength at normal temperature is 70 ~ 260MPa. Good thermal shock resistance. The sintered mullite and fused mullite brick two. Sintered mullite brick with high bauxite clinker as the main raw material, adding a small amount of clay or raw bauxite as binder, after molding, sintering and made. Fused mullite brick with high bauxite, alumina and refractory clay as raw material, adding charcoal or coke fines as a reducing agent, formed by reduction of electric melting method to manufacture. The crystallization of fused mullite is larger than that of sintered mullite, and the thermal shock resistance is better than that of sintered products. Their high temperature performance mainly depends on the content of alumina and the uniformity of the phase distribution of mullite and glass. [1]

- Q: The difference between the high aluminum corundum brick and corundum mullite brick

- Wall tiles and floor tiles are collectively referred to as ceramic tile flooring

- Q: What are the varieties of polycrystalline mullite?

- PNF-100 seriesThe PNF-100 series are made of polycrystalline mullite fiber cotton felt to cut, compress, and wrap into blocks without any adhesive.Characteristic: thermal shock resistancelow thermal conductivityLight weightSound absorption propertyLow thermal storage

- Q: Refractory bricks (mullite bricks) can be used on the walls of buildings?

- In many architectural design, high-rise fire rating is placed in the important position of the topic, especially when the floor height is more than 20 layers, we have more stringent requirements for the choice of fire resistant materials. The building wall, kitchen flue, boiler flue, flammable zone must use a firewall barrier, in many refractory refractory brick is the product of choice for fire resistance of refractory brick masonry is more stable.

Send your message to us

Mullite Brick - Low Apparent Porosity Insulating Fire Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords