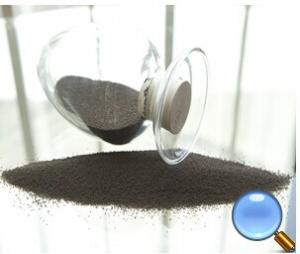

Monolithic Refractories for Cement Industry - Contaminative Resistant Tile Bottom Powder

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Application:

This product is used on the bottom of the tile body for avoiding ceramic glaze contaminating the ceramic rollers with function of prolonging service life of ceramic rollers. Aokerola Group developed a new generation tile bottom powder which adds special ingredient to protect rollers and improve rate of qualified products.

2. Guidance for using:

1) Put this material and water into the ball mill for mixing according to the proportion 1:2.5 then take out after two hours or mix directly according to the proportion.

2) Taking the slurry out and then add some water with standard while the baume shows 24~25 degree (Bulk density 1.10-1.25).

3) Painting the slurry on the bottom of tile body in through glaze line.

3. Advantages Analysis:

1)Reducing the transmutation rate of products and increase the rate of quality products.

2)Prolonging the roller replacing time (50%-80%) and the service life of rollers .

3)Releasing the intensity of workers and improving productivity.

4)Lower price than alumina powder

- Q: The research direction of unshaped refractory for cement kiln

- Refractory materials used in cement kilns contain stereotypes and amorphous forms

Send your message to us

Monolithic Refractories for Cement Industry - Contaminative Resistant Tile Bottom Powder

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords