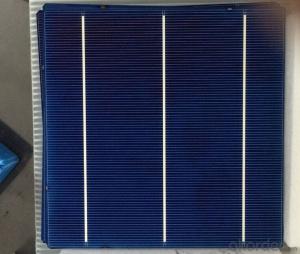

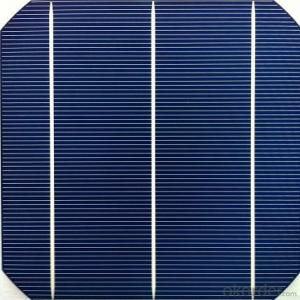

UV Monocrystalline Solar Cells Format:156 mm x 156 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Monocrystalline Solar Cells A GRADE

A solar cell, is an electrical device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physical and chemical phenomenon. It is a form of photoelectric cell, defined as a device whose electrical characteristics, such as current, voltage, or resistance, vary when exposed to light. Solar cells are the building blocks of photovoltaic modules, otherwise known as solar panels.

Advantage of Monocrystalline Solar Cells

1.Tire-1 Solar Cells’ Manufacturer Quality Guarantee. With a complete and sophisticated quality government system, our Quality Management have arrived world’s leading place. Customer can receive Tire-1 Cells Maker’s Quality Standard Products.

2.Trusted Warranty. We can supply trusted after-sales service to our customer. If our cells are found not in conformity to the specification of manufacturer, or should the inspected quantity found in shortage, or should the packing found damaged, the buyer has the right to claim to the seller. The claim, if any, should be presented to seller within 30 days after cargo's arrival date to the port, together with related inspection report and photos issued and provided by a reputable independent surveyor such as SGS.

3.World’s Leading Manufacturer Equipment. We imported the newest and leading production equipment from abroad. Advanced equipment can guarantee the stable quality of cells. Auto production line can also save labor cost which will further cut our production cost.

Specifications of Monocrystalline Solar Cells

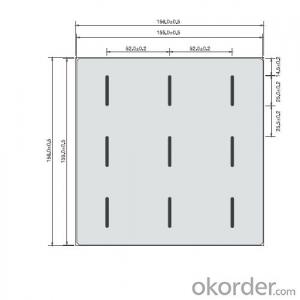

Format : 156 mm × 156 mm ± 0.5 mm

Thickness: 210 μm ±40 μm

Front (-) : 1.5mm bus bars (silver),blue anti-reflection coating (silicon nitride)

Back (+) : 2.5mm wide soldering pads (silver) back surface field (aluminium)

Efficiency (%) Pmpp (W) Umpp (V) Impp (A) Uoc (V) Isc (A) |

18.20% 4.43 0.536 8.263 0.634 8.712 |

18.00% 4.38 0.535 - 8.188 0.633 8.701 |

Usage of Polycrystalline Solar Cells

Solar cells are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting the semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current; our solar cells have passed IEC Certification. With high and stable quality, our cells can greatly improve the performance of Solar Modules.

FAQ

We have organized several common questions for our clients,may help you sincerely:

1.What’s price per watt?

A: It’s depends on the quantity, delivery date and payment terms of the order. We can talk further about the detail price issue. Our products is high quality with lower price level.

2.Can you tell me the parameter of your solar cells?

We have different series of cells with different power output, both from c-si to a-si. Please take our specification sheet for your reference.

3.How do you pack your products?

We have rich experience on how to pack the panels to make sure the safety on shipment when it arrives at the destination.

4.Can you do OEM for us?

Yes, we can.

5.How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The perfect time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

How solar cells are made

How the new materials change the made processes of solar cells.

At present, most of the solar battery board's advocated material is crystalline silicon. Crystal itself or crystal sediments above can be mixed with some other metal atoms, the atoms can combine with the silicon atoms and appear electrons, electrons can selectively generates hole, both of them can enhance the conductivity of crystal. After doping process of crystalline silicon solar cell conversion efficiency can be more than 20%, and without doping battery's efficiency never exceeded 14%.

Doping process can improve the conversion efficiency of solar energy, but it will increase the complexity of the semiconductor devices and lower its performance, exam the following manufacturing processes. Special hybrid materials in the new study can omit doping process, only need seven simple steps, it can combine new materials and simple coating process to improve efficiency. As the department of energy's Lawrence Berkeley national laboratory and the university of California, Berkeley, visiting scholar, James & dot; Block the related achievements as the first author published in the journal nature & dot; energy, he said: "we're making solar cells structure is simple, can effectively reduce the cost."

In this study, the research team at the side of the solar battery for solar silicon wafer, coated with a thin layer of molybdenum oxide, lithium fluoride is used on the back of the material. Both of the coatings only have dozens of nanometers thick and they are transparent. Because of the complementary electronic structure, it becomes very suitable for use in a solar cell.

Made your own simplest Solar Cell

Use the metal sheers to cut two pieces of copper approximately 3” x 4”. Place one piece of copper directly on the electric burner at high heat. As the copper starts to heat up, you will see an oxidation pattern start to form. After a few minutes, the colors from the oxidation pattern will be replaced by a thick black cupric oxide (CuO) coating. Leave the copper plate on high heat for one half hour to develop a thick black oxide layer. After one half hour turn off the burner and let the copper sheet slowly cool on the burner allowing the cupric oxide layer to flake off exposing a reddish-orange cuprous oxide (Cu2O) layer underneath. Once cooled, remove the copper plate from the burner and gently flake off the remaining black cupric oxide using a paper towell or by running water over it.

Cut the top off of the plastic water bottle. Bend both the heat-treated copper plate and the clean copper plate to fit on the inside of the plastic water bottle. The two sheets should not touch. Next attach an alligator clip to each sheet and attach the positive terminal of the meter to the clean copper plate and the negative terminal to the cuprous oxide coated plate.

Dissolve two tablespoons of salt in about two cups tap water, and fill the water bottle with salt water leaving about an inch at the top to avoid getting the alligator clips wet.

Once the cell is complete take a meter reading both indoors and outside. In direct sunlight, the multimeter should read a current of up to 50 microamps and a voltage of approximately 0.25 volts.

- Q: What is the role of solar cells in powering streetlights?

- The role of solar cells in powering streetlights is to harness sunlight and convert it into electricity. This electricity is then stored in batteries, which are used to power the streetlights during nighttime or when there is not enough sunlight available. Solar cells enable streetlights to operate independently from the electrical grid, reducing energy costs and environmental impact.

- Q: How do solar cells generate electricity at night?

- Solar cells do not generate electricity at night as they rely on sunlight to convert photons into electrical energy.

- Q: How do solar cells perform in areas with high levels of industrial emissions?

- Solar cells can still perform effectively in areas with high levels of industrial emissions. While industrial emissions can potentially reduce the overall performance of solar cells due to air pollution and particulate matter, the impact can vary depending on the specific pollutants and their concentration. Regular cleaning and maintenance of the solar panels can help mitigate any negative effects. Additionally, advancements in solar cell technology, such as anti-reflective coatings and improved efficiency, can enhance their performance even in challenging environments.

- Q: How do solar cells perform in dry desert conditions?

- Solar cells perform very well in dry desert conditions. The abundance of sunlight and low humidity levels in deserts make them ideal environments for solar energy generation. The absence of cloud cover and dust particles allows solar cells to efficiently convert sunlight into electricity, resulting in higher energy production. Additionally, the heat in desert regions can actually benefit solar cells, as higher temperatures can increase their efficiency. Overall, solar cells are highly effective and efficient in dry desert conditions.

- Q: Can solar cells be used for refrigeration?

- Yes, solar cells can be used for refrigeration. Solar-powered refrigeration systems utilize solar cells to convert sunlight into electricity, which is then used to power the refrigeration process. This technology is particularly useful in off-grid or remote areas where access to electricity is limited. It allows for sustainable and environmentally-friendly refrigeration solutions.

- Q: What is the impact of dust and dirt on solar cell performance?

- Dust and dirt can significantly impact the performance of solar cells. When dust and dirt accumulate on the surface of solar panels, they reduce the amount of sunlight that reaches the cells, resulting in a decrease in energy production. The presence of dust and dirt also creates a layer on the surface, which can cause hotspots and increase the temperature of the solar cells, further reducing their efficiency. Regular cleaning and maintenance are essential to maximize the performance and lifespan of solar cells.

- Q: How do solar cells impact national energy policies?

- Solar cells have a significant impact on national energy policies by driving the shift towards renewable energy sources. As solar power becomes more affordable and efficient, governments are incentivized to promote its adoption through various policies and initiatives. This includes providing subsidies and tax incentives to encourage investment in solar energy, setting renewable energy targets, and implementing net metering policies that allow consumers to sell excess electricity back to the grid. The wide-scale deployment of solar cells helps diversify energy sources, reduce dependence on fossil fuels, and mitigate climate change, thereby shaping and influencing national energy policies.

- Q: Are solar cells safe for the environment?

- Yes, solar cells are safe for the environment. They generate electricity without emitting harmful greenhouse gases or pollutants, making them a clean and sustainable source of energy. Additionally, their production and operation have minimal impact on ecosystems compared to fossil fuel-based power generation.

- Q: Can solar cells be used to power water pumps or irrigation systems?

- Yes, solar cells can indeed be used to power water pumps or irrigation systems. Solar cells convert sunlight into electricity, which can be stored in batteries or used directly to power water pumps. This provides a sustainable and renewable energy source for pumping water for irrigation purposes, even in remote areas without access to the grid.

- Q: What is the impact of snowmelt on solar cell efficiency?

- The impact of snowmelt on solar cell efficiency is generally positive. Snowmelt helps to remove any snow cover on solar panels, allowing them to receive more sunlight and generate more electricity. This increased exposure to sunlight improves the efficiency of the solar cells and enhances their performance. Additionally, snowmelt also helps to prevent any potential damage that could occur due to the weight of accumulated snow on the panels.

Send your message to us

UV Monocrystalline Solar Cells Format:156 mm x 156 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords