Monocrystalline Solar Cells A Grade 156*156mm with Trusted After-sales Service

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Monocrystalline Solar Cells A GRADE 156*156mm

Solar cells is made by solar wafer, it has three categories of solar cell right now, monocrystalline polycrystalline and thin film,These cells are entirely based around the concept of ap-n junction, which is the critical part of solar module, it is the part that can convert the light energy into electricity, the thickness is from 180um to 200um, with even busbars to conduct electricity, textured cell can decrease diffuse reflection; they are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current;With high quality and stable quality. Our Cells can greatly improve the performance of Solar Modules.

Advantage of Monocrystalline Solar Cells

1. Tire-1 Solar Cells’ Manufacturer Quality Guarantee. With a complete and sophisticated quality government system, our Quality Management have arrived world’s leading place. Customer can receive Tire-1 Cells Maker’s Quality Standard Products.

2. Trusted Warranty. We can supply trusted after-sales service to our customer. If our cells are found not in conformity to the specification of manufacturer, or should the inspected quantity found in shortage, or should the packing found damaged, the buyer has the right to claim to the seller. The claim, if any, should be presented to seller within 30 days after cargo's arrival date to the port, together with related inspection report and photos issued and provided by a reputable independent surveyor such as SGS.

3. World’s Leading Manufacturer Equipment. We imported the newest and leading production equipment from abroad. Advanced equipment can guarantee the stable quality of cells. Auto production line can also save labor cost which will further cut our production cost.

4. Bulk supply: With the production capacity of 500MW, we can produce large quantity every month. This can satisfy most customer requirement.

Specification:

Efficiency (%) Pmpp (W) Umpp (V) Impp (A) Uoc (V) Isc (A) |

18.20% 4.43 0.536 8.263 0.634 8.712 |

18.00% 4.38 0.535 - 8.188 0.633 8.701 |

17.80% - 4.33 0.534 - -8.112 ---0.632 ----8.652 |

17.60% 4.28 0.533 8.036 0.631 8.641 |

17.40% 4.23 0.529 8.005 0.630 8.591 |

17.20% 4.19 0.525 7.973 0.627 8.542 |

17.00% 4.14 0.522 7.926 0.624 8.495 |

16.80% 4.09 0.518 7.893 0.620 8.452 |

16.60% 4.04 0.515 7.844 0.617 8.410 |

16.40% 3.99 0.514 7.765 0.616 8.373 |

16.20% 3.94 0.511 7.715 0.615 8.317 |

16.00% 3.89 0.509 7.650 0.613 8.251 |

Usage of Monocrystalline Solar Cells

Solar cells are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting the semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current; our solar cells have passed IEC Certification. With high and stable quality, our cells can greatly improve the performance of Solar Modules.

Applications of Monocrystalline Solar Cells

Assemblies of photovoltaic cells are used to make solar modules which generate electrical power from sunlight, as distinguished from a "solar module" or "solar panel". A solar array generates solar power using solar energy.

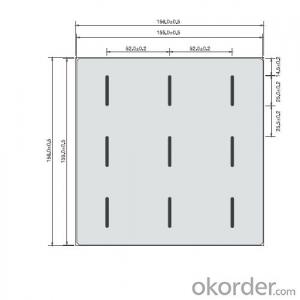

Packaging & Delivery of Monocrystalline Solar Cells

Carton Box Package and Deliver by air. It should be noticed that it should be avoid of water, sunshine and moist.

FAQ

We have organized several common questions for our clients,may help you sincerely:

①What price for each watt?

It depends on the efficiency of the solar cell, quantity, delivery date and payment terms.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③Can you provide the peripheral products of the solar panels, such as the battery, controller, and inverter? If so, can you tell me how do they match each other?

Yes, we can, we have two companies for solar region, one is CNBM International, the other is CNBM engineering Co.

We can provide you not only the solar module but also the off grid solar system, we can also provide you service with on grid plant.

④What is your warranty of solar cell?

Our product can promise lower than 0.3% open box crack, we support claim after opening the box if it has crackm color difference or sth, the buyer should give pictures immediately, we can not accept the claim after the solar cell has assembled to solar panel.

• Timeliness of delivery

• ⑤How do you pack your products?

We have rich experience on how to pack the solar cell to make sure the safety on shipment, we could use wooden box or pallet as buyer's preference.

⑥ Can you do OEM for us?

Yes, we can.

In order to reduce production costs, ground applications such as mono solar cell 156mm using solar grade silicon rods, materials performance has been relaxed. Some also use semiconductor device processing materials and discard the head and tail of silicon materials, solar cells drawn into complex dedicated silicon rods.

The silicon rods cut into pieces, usually 0.3 mm thick sheet. Processing mono solar cell 156mm, the first doping and diffusion in silicon, a trace amount of dopant is generally boron, phosphorus, and antimony. Diffusion is carried out in a quartz tube into a high-temperature diffusion furnace. Thus formed P> N junction on the wafer. Then using a screen printing method, fine with a good paste into a grid line printed on the wafer, after sintering, while forming the back electrode and the surface coated with antireflection gate line source to prevent a large number of photons It is reflected off the smooth surface of the wafer.

Thus, mono solar cells 156mm are produced. After single-chip random testing can be assembled according to the required specifications into a solar cell module (solar panel) by the method of series and parallel to a certain output voltage and current. According to user system design, solar cell components of various sizes square solar cells, also known as solar arrays. Photoelectric conversion efficiency of monocrystalline silicon solar cells is about 15%, the results of the laboratory also has more than 20%.

Crystalline silicon solar cell includes two battery and thin film batteries, their characteristics determine that they have an irreplaceable role in the different applications. However, the next 10 years the share of crystalline silicon solar cells although due to the development of thin film solar cells and other reasons decline, but its dominance is still not fundamentally changed; and thin film batteries can be solved if the conversion efficiency is not high, thin film batteries used in the preparation of equipment is expensive and other issues, will be a huge space for development.

- Q: Can solar cells be used in recreational vehicles?

- Yes, solar cells can be used in recreational vehicles (RVs). Solar panels can be installed on the roof of an RV to harness sunlight and convert it into electricity, which can then be used to power various appliances and systems within the vehicle. This allows RV owners to enjoy the benefits of renewable energy while traveling and reduces the need for traditional power sources.

- Q: Can solar cells be used for powering manufacturing facilities?

- Yes, solar cells can be used to power manufacturing facilities. By installing a solar panel system, manufacturing facilities can generate renewable and clean energy to meet their power needs. This not only reduces their dependence on fossil fuels but also helps in reducing their carbon footprint and overall environmental impact.

- Q: Can solar cells be used for powering streetlights?

- Yes, solar cells can be used for powering streetlights. Solar-powered streetlights use photovoltaic panels to convert sunlight into electricity, which is then stored in batteries for use during the night. This sustainable and renewable energy source eliminates the need for traditional grid electricity, reducing costs and environmental impact.

- Q: Can solar cells be used in hybrid systems?

- Yes, solar cells can indeed be used in hybrid systems. Hybrid systems combine multiple sources of energy, such as solar, wind, or traditional grid power, to ensure a more reliable and efficient energy supply. Solar cells can be integrated into these hybrid systems to generate electricity from sunlight, which can be used alongside other sources to meet the energy demands of a particular system or application.

- Q: Can solar cells be used in data centers or server farms?

- Yes, solar cells can be used in data centers or server farms. They can be installed on the rooftops or surrounding areas of these facilities to harness solar energy and convert it into electricity. This renewable energy source can help offset the power consumption of data centers and server farms, reducing their carbon footprint and reliance on traditional energy sources.

- Q: Can solar cells be used for powering space missions?

- Yes, solar cells can be used for powering space missions. Solar cells convert sunlight into electricity, providing a reliable and sustainable power source for space exploration. They have been extensively used on spacecraft and satellites to generate electricity for various systems and instruments.

- Q: Can solar cells be used for powering schools?

- Yes, solar cells can be used to power schools. Solar energy is a renewable and sustainable source of power, and installing solar panels on school rooftops or grounds can generate electricity to meet the energy needs of schools. This can significantly reduce the reliance on fossil fuels and decrease carbon emissions, making it an environmentally friendly solution. Additionally, solar power can provide a reliable and consistent energy source, especially in sunny regions, ensuring schools have a stable power supply.

- Q: Is it complicated to make a solar cell work well?

- For the professionals, it is not complicated at all.

- Q: What are the safety considerations when installing solar cells?

- When installing solar cells, it is important to consider several safety precautions. First and foremost, it is essential to work with a qualified and experienced installer who understands the necessary safety protocols. Additionally, proper electrical safety measures should be taken, such as turning off the power supply and using insulated tools. It is crucial to follow all manufacturer instructions and guidelines to ensure safe installation. Working at heights should also be approached with caution, using appropriate fall protection equipment when necessary. Lastly, it is important to be aware of potential hazards such as sharp edges, hot surfaces, and electrical shock risks. Regular maintenance and inspections should be conducted to ensure ongoing safety.

- Q: How do solar cells perform in regions with high levels of dust and sandstorms?

- Solar cells can be affected by dust and sandstorms in regions with high levels of such conditions. The accumulation of dust particles on the surface of solar panels can reduce their efficiency by blocking sunlight and creating a layer of insulation. Regular maintenance, such as cleaning the panels to remove dust and debris, is crucial to ensure optimal performance. Additionally, advancements in solar panel designs, such as anti-reflective coatings and self-cleaning mechanisms, are being developed to mitigate the impact of dust and sandstorms on solar cell performance in these regions.

Send your message to us

Monocrystalline Solar Cells A Grade 156*156mm with Trusted After-sales Service

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords