Solar Energy - Best Quality Flexible Solar Cells with CE, RoHS, ICE Certification

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Model Number: | ANM250M-96 | ||||

| Material: | Monocrystalline Silicon | Size: | 1575*1082*50 | Number of Cells: | 250 |

| Max. Power: | 250 | Certificate: | CE, ROHS, ICE | Warranty: | 5 years |

| keywords: | flexible solar cell | Short circuit current(Isc): | 5.95 | Open circuit voltage(Voc): | 58.40 |

| Current at max power(Imp): | 5.28 | Voltage at max power(Vmp): | 47.33 | Max. Power (Pm): | 250 |

| Operate Temp. scope: | -40~85 | Impact Resistance: | AC2000V; DC3000V |

Packaging & Delivery

| Packaging Detail: | standard export package suitable for long seavoyage and tough handling |

| Delivery Detail: | 10-25 days depending on order quantity |

Specifications

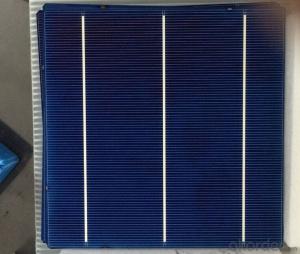

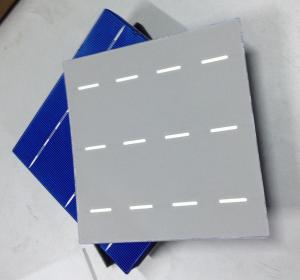

flexible solar cell

1.Monocrystalline

2.Solar Panel Factory

3.CE, ROHS, IEC

4. 5yrs warranty

Types of Solar Cell

Current solar cells are classified into several types according to the material, structure and the manufacturing method used. Wherein the multi-crystalline silicon solar cell refers to the silicon semiconductor substrate is a monocrystalline silicon solar cells and a raw material polycrystalline silicon solar cells; in addition to amorphous silicon-based solar cells, such batteries with the liquid crystal panel prepared by the same film is based, it is deposited on a silicon substrate instead of a glass substrate made of amorphous silicon.

Monocrystalline silicon solar cells are formed on a monocrystalline silicon substrate, but also the conversion efficiency up to 20% of the products, with excellent performance and reliability characteristics. However, as the price of raw materials expensive silicon substrate, the higher cost of electricity per watt. Although polycrystalline silicon solar cell conversion efficiency is lower than that of silicon solar cells, with the advantage of cheap cost.

Most substrate monocrystalline and polycrystalline silicon solar cell used is from the slowly cooled liquefied silicon after heating the crystalline silicon block (ingot) cut out of the sheet manufacturing. Forming a polycrystalline silicon solar cell uses polycrystalline silicon ingots; forming a single crystal silicon solar cell uses single crystal silicon ingot. Compared with polysilicon ingot, single crystal silicon ingot production efficiency is lower, therefore more it is more expensive.

The more cutting thin silicon substrate, the silicon ingot obtained by the same base plate number, the more, the lower the cost. However, there are also disadvantages sheet cut easily broken during the manufacturing process. So how global materials manufacturers around the sheet during cutting and increase yield, reduce cost in a fierce competition.

Using a thin film of amorphous silicon solar cell production method is different significantly reduce the amount of silicon used, and vacuum evaporation using a manufacturing process suitable for mass production, as compared with the crystalline type can significantly reduce costs, but the amorphous silicon solar cell lower conversion efficiency is only about 10%. Such batteries silicon feedstock prices of the period of concern, but with the tight silicon market weaker than expected growth in its share.

- Q: Can solar cells be used to power water purification systems?

- Yes, solar cells can be used to power water purification systems. Solar cells convert sunlight into electricity, which can be used to power various devices, including water purification systems. This sustainable and renewable energy source is often utilized in remote areas or during emergencies where access to electricity may be limited.

- Q: Can solar cells be used for off-grid power supply?

- Yes, solar cells can be used for off-grid power supply. Solar cells, also known as photovoltaic cells, convert sunlight into electricity. These cells can be used to generate electricity in remote areas or locations where the traditional power grid is unavailable or unreliable. Solar panels can be installed on rooftops or in open spaces to capture sunlight and produce electricity, which can then be stored in batteries for use during non-sunlight hours or when needed. This makes solar cells an efficient and sustainable solution for off-grid power supply.

- Q: Can solar cells be used to charge batteries?

- Yes, solar cells can definitely be used to charge batteries. Solar cells convert sunlight into electricity, which can be used to charge batteries for various applications such as powering small devices or storing energy for later use.

- Q: What is the role of solar cell inverters in grid-tied systems?

- The role of solar cell inverters in grid-tied systems is to convert the direct current (DC) energy generated by solar panels into alternating current (AC) energy that is compatible with the electrical grid. These inverters ensure that the solar energy produced by the panels can be used to power appliances and devices in homes or businesses, and any excess energy can be fed back into the grid for others to use. Additionally, solar cell inverters also provide important safety features, such as isolating the solar system from the grid during power outages to protect utility workers.

- Q: How do solar cells perform in tropical climates?

- Solar cells perform well in tropical climates due to the abundance of sunlight and high temperatures found in these regions. The intense sunlight allows solar cells to generate a higher amount of electricity, while the warmer temperatures can actually increase the efficiency of the cells. Additionally, solar panels are designed to withstand harsh weather conditions, including high humidity and heavy rain, commonly found in tropical climates.

- Q: Can solar cells be used to power remote weather stations?

- Yes, solar cells can be used to power remote weather stations. Solar cells convert sunlight into electricity, providing a reliable and sustainable power source for remote areas where access to the grid may be limited or nonexistent. This makes solar cells an ideal solution for powering weather stations in remote locations, ensuring continuous operation and accurate weather data collection.

- Q: Can solar cells be used for powering internet connectivity?

- Yes, solar cells can be used for powering internet connectivity. Solar cells generate electricity from sunlight, which can be used to power various devices, including routers, modems, and other networking equipment. This enables internet connectivity in remote areas where traditional power sources may not be available, making solar-powered internet an efficient and sustainable solution.

- Q: Can solar cells be used to power electronic devices?

- Yes, solar cells can be used to power electronic devices. Solar cells convert sunlight into electricity, which can then be used to power a wide range of electronic devices such as smartphones, laptops, calculators, and even larger appliances like refrigerators or streetlights. This allows for a sustainable and renewable source of energy for various applications.

- Q: How do solar cells affect the local ecosystem?

- Solar cells have a minimal impact on the local ecosystem. Unlike traditional energy sources, solar cells do not produce harmful emissions or pollution during their operation. Additionally, solar farms can be designed to coexist with the natural environment by incorporating measures like landscaping and wildlife-friendly habitats. Overall, solar cells contribute positively to the local ecosystem by promoting clean energy and reducing carbon emissions.

- Q: Can solar cells be used for powering airports?

- Yes, solar cells can be used for powering airports. Solar energy is a sustainable and renewable source of power, and airports have large areas of open space that can be utilized for installing solar panels. By harnessing the power of the sun, airports can reduce their reliance on non-renewable energy sources, lower their carbon footprint, and potentially save on energy costs in the long run. Additionally, solar power can also be stored in batteries for use during non-sunny periods or at night, ensuring a continuous power supply for critical airport operations.

Send your message to us

Solar Energy - Best Quality Flexible Solar Cells with CE, RoHS, ICE Certification

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords