Mobile Series Concrete Placing Boom HG17B/HG15B

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

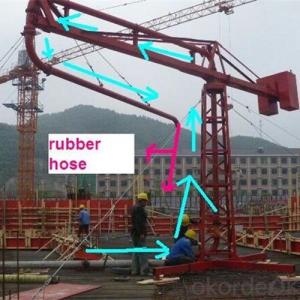

The placing boom has a Z-shaped boom assembly with three foldable sections, which can swing through 360 degrees while luffing, folding/unfolding, thus allowing it to place concrete to form walls, pipes, columns, piles and other vertical structures without confined placement areas.

The boom assembly’s luffing; folding/unfolding and swinging are carried out hydraulically with buttons. The hydraulic and electrical system feature overload protectors, flow controls, alarms, phase sequence protectors and so on, which ensures the placing boom to have reliable performance, easy and smooth operation, and high safety.

Scope of Application of the Equipment

The HG15B(HG17B)concrete placing boom is a concrete placer for combined use with a concrete pump in concrete placement operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This equipment can only be used in concrete construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The equipment is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Product Advantages:

OKorder's Concrete placing boom Channels are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Product Specifications:

◇ Maximum operating radius of the placing boom: 15000 mm

◇ Maximum placing height of the placing boom: 14120 mm

◇ Maximum placing depth of the placing boom: 10300 mm

◇ Range of elevation of the placing boom: -4˚~86˚

◇ Range of gyration of the placing boom: Full gyration

◇ Power of the hydraulic system's motor: 5.5kW

◇ Operating pressure of the hydraulic system: 22MPa

◇ Gyrating speed: 0.3 r/min

◇ Specifications of the concrete pipeline: φ133×4.5

◇ Length of the hose connected to the boom end: 3 m

◇ Span between outriggers:3325×3325 mm

◇ Mass of the complete machine: 3800 kg

◇ Counterweights' mass: 2400 kg

◇ External dimensions of the complete machine: 8133×3325×2180 mm

◇ The complete machine's vertical force under the most unfavorable operating condition: 67 kN

◇ The complete machine's horizontal force under the most unfavorable operating condition: 4 kN (with the boom placed vertically)

◇ Reaction to the complete machine's outrigger tips under the most unfavorable operating condition: 45 kN (with the boom aligned in the same direction as an outrigger)

◇ Pressure against the complete machine's outrigger tips under the most unfavorable operating condition: 57 N/cm2 (with the boom aligned in the same direction as an outrigger)

FAQ:

Q1: How to control the Placing Boom?

A1: The control system has two control modes for the user's selection: wireless remote control, and panel control.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Placing Boom according to customers request?

A4: Yes, we can produce Concrete Placing Boom according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Images:

- Q: How to install and use the distributor?

- Install the fuse according to the electricity consumption. No steel, aluminum or zinc wire shall be used instead of the fuse.

- Q: What is a fixed concrete distributor?

- Internal climbing concrete distributing machine is a kind of distributing equipment for high-rise building concrete construction. The ship borne concrete distributor is a special ship loading equipment for construction and design of harbors and docks

- Q: What do concrete pumps and fabrics mean?

- Automobile pump flexible tubing can flexibly rotate 360 degrees, the body shift is also very convenient, the pumping efficiency is relatively high, but the cost is more expensive.

- Q: what's the difference between the fabric pump and boom pump?

- The inner climbing type distributor is not limited by height

- Q: What is the Hand operated concrete distributor?

- It effectively solves the problem of pouring material into the wall, and plays an important role in improving the construction efficiency and reducing the labor intensity

- Q: How to maintain the concrete spreader?

- The lining of the silo is equipped with abrasion less material lining board to reduce material adhesion and reduce material arching

- Q: What is the structure of a concrete distributor?

- Structure: bolt, and the vertical frame, which is fixed on the base part, through the slewing bearing and the top rotating part is connected on the main beam, and the balance arm, the balance arm rod, such that after the formation of the upper transverse rotating part

- Q: What are the benefits of concrete handling machines?

- Concrete distributor; material ratio; sling construction; fabric safety

- Q: What is the concrete distributor?

- Concrete distributor is the end of pumping concrete, the function is to pump the pressure of concrete sent through the pipe to the casting components of the template

- Q: What's the design plan of the concrete spreader?

- The belt conveyor head sweeper is designed for the special requirement of conveying concrete and cleaning mortar. The scraper is made of hard alloy material, with a rectangular section, and it does not hurt the adhesive tape and the mortar loss is small

Send your message to us

Mobile Series Concrete Placing Boom HG17B/HG15B

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords