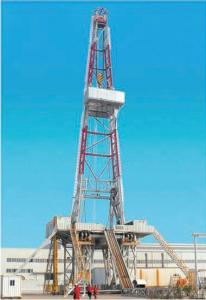

Mixer station LQC160,Cold Feed System,Drying and heating system

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Rated production capacity (with 5% moisture content) | 160t/h |

|---|---|

| Cold aggregate bin | 5 bins/40m3 |

| Output capacity | 180t/h |

| Drying drum specification | Φ2.2m×8.0m |

| Capacity (with 5% moisture content) | 180t/h |

| Bag filter: model/filtering area | PFK468/836 |

| Emission standard | ≤20mg/Nm3 |

| Screening-weighing-mixing system | |

| Vibrating screen | 5 layers/24m2 |

| Hot aggregate bin | 5/40t |

| Asphalt weight | 0~500Kg (automatic injection) |

| Mixing tank capacity | 2250kg |

| Mixing Cycle | 45s |

| Filler silo capacity | 2×20t |

| Asphalt tank capacity | 2×50,000L |

| Heat conduction oil furnace | 500,000kcal/h |

| Finished product bin capacity | 200t,120t,80t |

| System control: manual/semi-auto/auto·Chinese operating system·1000 recipes storage | |

| Measuring accuracy | |

| Aggregate | ≤±0.5% |

| Filler | ≤±0.3% |

| Asphalt | ≤±0.25% |

| Total installed power | 495kW |

Modular design, high productivity, low fuel consumption, environmental protection, globally sourced top quality components

Cold Feed System

Frequency-controlled belt feeder allows for independent and automatic adjustment of feed speed as per production and proportioning requirement. Sirens and warning lights are available to warn operators of aggregate starvation.

Collection and transfer belt is provided with belt tensioner and belt alignment device. Trough belt prevents aggregates from overflowing. Self-cleaning is available for smooth delivery.

The scalping screen removes any oversized material from the aggregates and lets properly sized aggregates enter the drying system, so energy is saved.

Modular design allows for various types of hopper combinations.

Highly Efficient Screening Unit

Developed and manufactured with techniques originated from Europe, the screening machine delivers long service life and high reliability. Adequate screening area and optimum match between vibration angle and inclination angle enable the vibration screen to meet the conditions for strict component proportioning and high screening efficiency. Amplitude and centrifugal force of the vibrating screen are adjustable to adapt to various proportioning. Screening efficiency(rated) ≥95%;messing rate(nominal) <5%.

Drying and heating system

Optimized flights and lifter design allows system to achieve a more uniform heating.

The thermal system is designed with overall optimal parameter control concept to ensure full burning with stability and high heat utilization. Drying and heating efficiency increased by 1-5%.

The dryer drum is insulated with rock wool mats against heat loss.

The dryer drum friction driven by four individual electric motors directly coupled to the nylon support roller shafts offers the advantages of high reliability, high efficiency, low noise emission and long service life. Currently, it’s widely regarded as the best one for drum drives.

Optional burners are available to operate on diesel oil, heavy oil, residual oil, natural gas, coal, etc.

Hot Mineral Silo

Large capacity hot mineral silo effectively ensures ongoing production of the asphalt mixing plant. Flaps operated through double-stroke cylinders for coarse and fine dosage are jam-free and of low maintenance.

Construction of storage silo and dosing flap is optimized with due consideration to cumulative weighing time and weighing accuracy. Rapid and accurate weighing ensures that all components in the recipe are proportioned as appropriate.

Continuous level sensor or maximum/minimum level sensor, temperature sensor, sampling chutes in mineral compartment and overflow channel enable you to have a thorough understanding of the operating conditions of all silo compartments.

Weighing Module

The weighing system with the weigh hopper resting on load cells maintains good weighing balance, thereby effectively resolving the problem of deviation of center of gravity.

World top brand load cells combined with automatic flying material dynamic adjustment module to ensure stable and accurate weighing.

Powerful negative pressure system of the mixing tower effectively isolates interference ensuring weighing accuracy during operation.

Top Quality Mixing Module

Pressurized bitumen is atomized via a multi-hole spray bar and filler is spirally distributed or discharged in axial direction of the mixer. Filler and asphalt are evenly distributed, thereby greatly reducing dry mixing times .

Twin shaft compulsory mixer, driven by geared motor units via equal gear wheels. The special mixer design featuring a double paddle arm pattern for powerful and intensive stirring behavior, with low rotation speed and large capacity, effectively avoids segregation and secondary gradation changes during mixing ensuring unrivalled mixing quality.

Mixer shafts with labyrinth seals to ensure zero leakage.

Skip Unit and Mixed Material Storage

Separated Silo Pattern

Automatic skip unit features frequency controlled gear motors and high speed pulse encoder giving precise control of skip speed and positioning. This total control of the skip allows it to be smoothly accelerated along the track and then slowed as it approaches the required station. Independent pneumatically operated brake ensures reliable braking and accurate positioning.

The skip features a rotary unpowered soft touch opening discharge door offering the advantages of safe operation, low impact, thorough discharging and no spillage of material, as compared to traditional lever impingement opening type skip door.

The special interior design of the storage silo could effectively stop stored materials from segregating.

Integrated Silo Pattern

Integrated silo pattern offers the advantages of low power consumption, low failure rates, low emissions, economic on space, little segregation, low heat loss, easy extensions, etc.

Be it a separated silo pattern or an integrated silo pattern, all such devices as material level indicators, remote or site discharge door control, electric heating elements fitted on the hopper around discharge door, skip door anti-stick agent no-pump sprayer, etc can be configured.

Bitumen Storage and Heating System

Full-function bitumen tank equipped with mixer, level indicator, and automatic temperature control valve.

Optional independent discharge system permits on-line discharge of thermal oil without affecting plant operation.

Number of bitumen tanks and layout as per customer specifications

The thermal oil heater equipped with a diesel oil burner provides automatic control of temperature thanks to a number of automated features. Examples include automatic ignition, automatic shutdown, automatic flame control and automatic fault-alarming.

Dust Collection System

Two-stage dust collection system; initial separator(gravity/cyclone) and bag filter, which has been recognized as one of the most efficient and reliable forms of dry dust collection with guaranteed emission levels of≤20mg/n.m3.

The energy-saving, low-noise rotating reverse air valve mechanism is used for more thorough bag cleaning.

Fully enclosed vibration screen, coupled with negative pressure design for mixing tower, effectively prevents leakage of dust.

Optional reclaimed filler silo and wet collectors (venturi scrubbers) minimize dust emission and solve the problem of transportation.

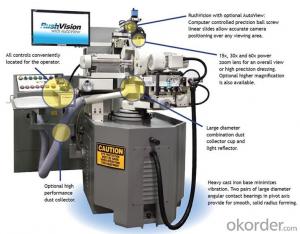

Control System

Two high performance industrial computers employing the latest hardware technology and software packages link together several groups of function modules to form one integral site network for automatic production control and management.

The two computers are designed to work in parallel for reliable plant control and higher information processing capacity.

The user interface is simple and logically structured. The overall plant operating status, the most important monitoring parameters and all fault messages can be followed online on the screen.

Powerful document management functions make your management easier.

The sound-proof, heat-isolation and dust-proof control cabin is effectively isolated from the electrical cabinet, giving the operator an optimum working environment.

Extensions

Full-open design allows the plant to be extended with a number of auxiliary functions and devices, such as SMA liquid, granular and fiber additive adding system, rubber asphalt supply system, RAP hot recycling, etc.

Service

Our service system supported by XCMG’s powerful global sales network does everything possible to provide maximum customer support from pre-sales, sales to after sales with quick response to spare parts needs, professional factory-trained engineers and positive attitude towards service.

- Q: BOOK OF PAGESBook of prophet Fronkey 11:33:44:56:789aAnd he say 'choot em' and he use the machinez with the pipes to take away aur soulz. And in heaven VegetableSkinMan say 'criae criae cryai' and then they try more sacrifice to great Marshmelo in field of treez. and will of Great Pumpkin is done..

- if you're going to attempt to insult someone, you should at very least make sure you're not a grammatical failure... also, souls do not exist, moron.

- Q: What are the big countries in the world?

- Germany, the United States, China, Japan and so on. I haven't got the exact rankings yet. Also, Russia is powerful, huh?

- Q: Like gears, pulley's and stuff. But not in a technical way, because before I make proper technical designs I need to be able to do rough sketches (don't ask why).

- Do isometric sketches. It's what I do. Lets you get a feel for what you are designing.

- Q: ...and after about 5 hours I developed a tight chest feeling and pain when I breathed too deep. It went away last night after I took some aspirin and rested, but I am wondering what it might be.Chemicals from the machinery? Glue fumes? (I was using spray adhesive on some items)

- There are men and women in this web page who will document others out of natural spite by the way, can I please ask EVERYONE to whinge approximately Violations whilst they aren't warranted.? A lot of men and women had been deleted just lately after operating very difficult to rise up to a degree wherein they are able to ask and reply limitless. If you get violated for whatever that's NOT even virtually being offensive, please document it with the e-mail header harassment through yet another person and state that you don't deserve this violation. Say that it's harassment and also you wish the problem investigated and the REPORTERS account suspended. I can be reporting EVERY one any longer Lets quit the senseless yobs destroying our paintings Just one factor despite the fact that. If you deserve the Violation - take it at the chin !

- Q: What is the management of construction machinery?

- (2) carry out the registration of construction hoisting machinery, equipment and use, and be responsible for implementing the notification system for construction departments and their safety supervision institutions;

- Q: Mechanical drawings, stiffeners, cutaway, right?

- On the vertical section of the stiffener, a section of the stiffener should be drawn and no cross section is required on the section parallel to the stiffener.

- Q: How come when working with machinery that vibrates alot ,such as a tiller, your hands feel itchy?

- Harmonic vibration reaction. The tone is just the right frequency to make your hands do this Just like when you tap a good Chrystal wine glass. And it makes our ears ring in return. -- -- --

- Q: Hi so I was just curious if I could get a good strength training workout without the machines like where you push with your legs or the machine where you pull the bar down and it pulls the weights up, I want to know if I can get a good daily workout with just my dumbbells and my bench, Detailed answers are greatly appreciated, any links to websites maybe? In advance I greatly appreciate helpful answers, thank you!

- Yes. I always prefer free weights to machines. That's not to say machines can be of benefit though... The machine where you 'pull down' isn't necessary. As an alternative, you could just do weighted chin-ups. The leg press machine is also replaceable with squats, lunges, etc. Machine exercises can be useful, but you can get by without them. *I'd highly recommend investing in a weight rack. It'll help with squats, shoulder presses, and other things.

- Q: LOL Industrial mechanization!

- LOL !! If only I had bought stock for the stuff in the very beginning !!

- Q: I need importers list of jewellery making machinery & cutting tools of diamond(except India)?

- GOOGLE MANUFACTURERS OF MACHINERY AND CUTTING TOOLS AND YOU WILL FIND PLENTY .

Send your message to us

Mixer station LQC160,Cold Feed System,Drying and heating system

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords