Mine Sieving Mesh -- The Best Quality Ever

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 3000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

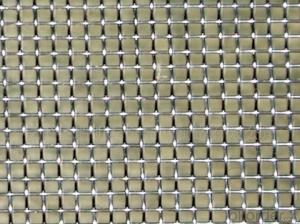

1.Structure of Mine Sieving Mesh Description

Manganese steel mine sieving mesh adopt inserting style to weave the mesh. The fold part of longitude and latitude won’t extrude so the surface is smooth. The hardness is HB180-230 and it has good character of molding and toughness. When it is suffering fierce strike and attrition, the surface is changed. The hardness of the surface can go up to HRC60, so it has good wearability. Inner side still has finer molding and toughness. It will form a new layer of wearability when the old surface is destroyed. Therefore the life of the woven mine sieving mesh can be achieved in 4-6 times than the ordinary mine sieving mesh

2.Main Features of the Mine Sieving Mesh

•Made of high quality steel wire.

•Various configurations and sizes

•Used for loose strata to aviod falling rocks.

•Suitable for shotcrete applications.

•Range of sizes to suit roadway width and bolting patterns.

•Easy installation,

•Avaliable in black or hot dip galvanized.

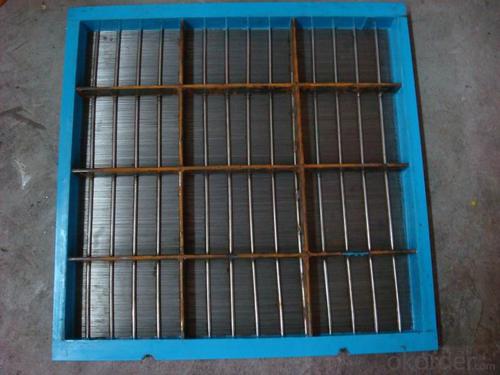

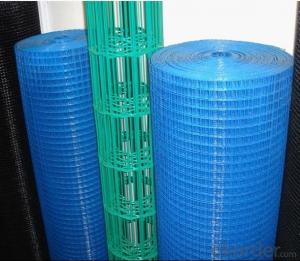

3. Mine Sieving Mesh Images

4. Mine Sieving Mesh Specification

Aperture (mm) | Specification (m) | Weight kg/piece | |

0.6 | 0.8×0.8 | 1.5×20 | 10 |

0.7 | 1.0×1.0 | 1.5×20 | 10 |

1.0 | 1.5×1.5 | 1.5×20 | 15 |

1.2 | 2.0×2.0 | 1.5×20 | 17 |

1.5 | 3.0×3.0 | 1.5×20 | 19 |

2.0 | 4.0×4.0 | 1.5×20 | 25 |

3.0 | 5.0×5.0 | 1.5×20 | 42 |

3.0 | 6.0×6.0 | 1.5×20 | 38 |

4.0 | 8.0×8.0 | 1.5×20 | 50 |

4.0 | 10.0×10.0 | 1.5×20 | 43 |

5.0 | 12×12 | 1.5×20 | 56 |

5.0 | 15×15 | 1.5×20 | 47 |

6.0 | 20×20 | 1.5×20 | 52 |

7.0 | 25×25 | 1.5×20 | 58 |

8.0 | 40×40 | 1.5×20 | 50 |

10.0 | 50×50 | 1.5×20 | 63 |

5.FAQ of Mine Sieving Mesh

①The general use?

Welded Wire Mesh with excellent corrosion resistance and oxidation resistance, is extensively used as fencing, decoration and machinery protection material in agriculture, construction, transport, mine, sports field, lawn and various industrial fields

② Our Advantages?

1. Low cost for molding or tooling

2. Advanced & Standardization workshops and facilitates.

3. High-tech and high precision manufacturing equipment.

4. Strict ISO14001:2004 , ISO9001:2008 standards.

5. ROHS compliant & enviroment friendly products.

6. Professional technical specialists and management personel

7. 100% in house inspection before delivery

③Why you choose us?

We can make high precision parts from foil as thin as 0.025mm.

Main metal material we can photo etching including:

Stainless steel, iron, brass, copper, Kovar, Molybdenum

Surface can be paint color, gold/silver plated or mirror finish

Products can be made according to your drawing in .dxf or .dwg format.

Please feel free to contact us for the quotation

- Q: What are the reasons for the hair making of the screen plate?

- Ink with hardening agent is also likely to cause the printing ink is not enough to produce the edge of the lack of ink and produce hair phenomenon.

- Q: Screen printing and other printing methods of the difference

- Ink variety, can print a variety of special effects, three-dimensional sense of strong. The printing method is infinitely changing.

- Q: The difference between screen printing characteristics

- The screen printing can be a large area of printing, the largest format up to 3 m × 4 m, or even greater.

- Q: What is the commonly used mapping software for screen printing?

- The principle of stencil printing is: the printing plate (paper version or other version of the foundation to produce through the ink hole) in the printing, through a certain pressure to the ink through the hole version of the hole transferred to the substrate (paper, ceramics ), The formation of images or text.

- Q: Screen printing has several characteristics

- The principle of stencil printing is: the printing plate (paper version or other version of the foundation to produce through the ink hole) in the printing, through a certain pressure to the ink through the hole version of the hole transferred to the substrate (paper, ceramics

- Q: Is the screen printing the best way? And other printing methods than it?

- Irregular printing can also be used for printing, but it is best to print the area is relatively small

- Q: Screen printing ink firmness problem

- If it is PVC tablecloth, you can try to corona the first surface of the printing process, so that the surface tension higher (recommended to 55 - 60 dyne), and then see if there is improvement.

- Q: Screen printing, how to choose the screen

- You have to choose according to different moments, printing different products, imports a little better

- Q: What is the screen printing plate?

- Silk cloth is generally the quality of domestic and imported polyester is far worse.

- Q: Screen printing and printing the difference

- ink, pressure and other processes, so that ink transferred to paper, fabric, Leather and other materials on the surface, the bulk copy of the original content of the technology.

Send your message to us

Mine Sieving Mesh -- The Best Quality Ever

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 3000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords