Customized Aluminum Coils - Mill Finished Aluminium Coil AA8079 Temper H24

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Aluminum Coil Description:

Aluminum coil, is a rolled product, produced in a coiled form of continuous strip, and having an ID (Inner diameter) and OD (Outer diameter).Common alloy coil are used for a wide variety of applications, alloy 1050, 1060, 3003, 3105, 3005, 5052, 5754, 5083, 6061, 8011, 8021, and so on, in thickness from 0.0065-7mm, in width from 300- 2200mm.

Aluminium coil can be deep processed into aluminium foilstock, aluminium circle, aluminium coating products, aluminium ceiling, aluminium plastic composite panel (APCP), aluminium embossed products, etc.

2.Main Features of the Aluminum Coil:

• Great ductility

• Heat conductivity

• Anti-corrosion

• Moisture resistanve

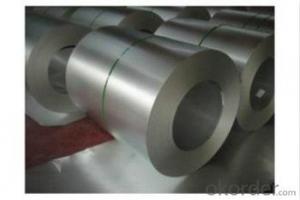

3.Aluminum Coil Images

4.Aluminum Coil Specification

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006, AA8079 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F |

Thickmess | ≥0.2mm |

Width | 30mm-2100mm |

Standard | GB/T 3880-2006 |

Special specification is available on customer's requirement | |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product. we have strict quality test; we resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(2) MOQ?

For trail order, we accept 3 MT.

(3) Payment term?

30% deposit, balance against the BL copy; 100% L/C at sight

(4) What is the delivery time?

Depends on actual order, around 30 to 35 days

- Q: What are the common sizes and thicknesses of aluminum coils?

- The sizes and thicknesses of aluminum coils differ depending on the application and industry. However, there are standard sizes and thicknesses that are commonly utilized across various industries. Regarding size, aluminum coils typically span from approximately 12 to 72 inches in width. This range allows for adaptability in accommodating diverse production processes and equipment. The length of the coils can also vary, but it often falls within the 1000 to 6000 feet range. Concerning thickness, aluminum coils are available in different gauges, typically measured in inches or millimeters. The most frequently employed thicknesses for aluminum coils range from 0.019 inches (0.48 mm) to 0.125 inches (3.18 mm). These thicknesses are suitable for a broad array of applications, including roofing, construction, automotive, and manufacturing. It is important to note that these are general guidelines, and the specific requirements for size and thickness may differ depending on the intended use of the aluminum coils. Additionally, custom sizes and thicknesses can also be manufactured to fulfill specific project requirements.

- Q: What are the different alloy grades used in aluminum coils?

- Aluminum coils employ various alloy grades, each possessing distinct properties and applications. Among the commonly used grades are the following: 1. 1100: Commercially pure aluminum grade renowned for its remarkable corrosion resistance and high thermal conductivity. Frequently utilized in applications necessitating good formability, like fin stock, heat exchangers, and chemical equipment. 2. 3003: This alloy grade boasts moderate strength and excellent workability. It finds extensive use in applications requiring both corrosion resistance and formability, such as packaging, cooking utensils, and general sheet metal work. 3. 5052: Offering a compelling combination of strength, formability, and corrosion resistance, this alloy grade is often employed in marine environments and transportation equipment like fuel tanks and vehicle bodies. 4. 6061: A heat-treatable alloy grade recognized for its outstanding strength and weldability. Commonly utilized in structural applications like bridges, aircraft parts, and bicycle frames. 5. 7075: Another heat-treatable alloy grade renowned for its high strength-to-weight ratio. Frequently employed in aerospace applications and the fabrication of high-stress components, including firearm parts and rock climbing equipment. These examples merely represent a fraction of the various alloy grades employed in aluminum coils. The choice of the appropriate grade hinges on the specific requirements of the application, encompassing desired strength, corrosion resistance, formability, and thermal conductivity.

- Q: What’s the difference between aluminum tile, coil and sheet? Why?

- Wood pallet is often used, which is easy to transport and can ensure the safety of products.

- Q: How are aluminum coils protected against dust and dirt during storage?

- Aluminum coils are protected against dust and dirt during storage through various measures to ensure their quality and prevent any potential damage. One common method is to wrap the coils securely with a protective covering, such as plastic or polyethylene sheets, to create a barrier against dust and dirt particles. This covering is usually tightly sealed to prevent any contaminants from entering. In addition to the wrapping, other precautions are taken to minimize the risk of dust and dirt accumulation. Storage areas are often kept clean and free from debris to reduce the likelihood of contaminants settling on the coils. Regular cleaning and maintenance of the storage space are necessary to maintain a dust-free environment. Moreover, proper ventilation and air filtration systems are employed in storage facilities to control airborne particles and maintain a clean atmosphere. These systems help to reduce the amount of dust and dirt that can settle on the coils. It is also crucial to handle the aluminum coils with care during transportation and storage to avoid unnecessary exposure to dust and dirt. Employing proper handling equipment and techniques, such as using clean gloves and avoiding dragging the coils on the ground, can prevent the accumulation of contaminants. By implementing these protective measures, aluminum coils can be stored safely and securely, ensuring their quality remains intact and preventing any potential issues caused by dust and dirt accumulation.

- Q: Which is better composite or aluminum, and what are some main differences between the two?

- There are great bats that are made out of each, but I generally tend to think that composite bats have better performance. There are aluminum bats that may be better than a given composite, but generally a high-end composite will be better than a high-end aluminum. Composites tend to have larger sweet spots, some span the entire length of the barrel, and the ball will still travel well if hit towards the outside of the sweet spot. contact hitters should look towards composites, because their slower swings will be compensated for with the spring action of the composite material. I think aluminums are better for power hitters because that material has been used for decades and the weight distribution has been better perfected for harder swings.

- Q: Can aluminum coils be used in power generation facilities?

- Yes, aluminum coils can be used in power generation facilities. Aluminum is a highly conductive material that offers several advantages for power generation applications. It has excellent thermal conductivity, meaning it can efficiently transfer heat away from the coils, which is crucial for cooling systems in power generation facilities. Additionally, aluminum is lightweight, making it easier to handle and install compared to other metals like copper. This lightweight property also reduces the overall weight of the equipment, resulting in cost savings. Furthermore, aluminum is corrosion-resistant, which is important for power generation facilities that often operate in harsh environments. Overall, aluminum coils are a viable option for power generation facilities due to their conductivity, thermal efficiency, lightweight nature, and corrosion resistance.

- Q: Can aluminum coils be customized to specific thicknesses and widths?

- Indeed, it is possible to tailor aluminum coils to meet specific thicknesses and widths. These coils find extensive utilization across numerous sectors like construction, automotive, and aerospace, considering their distinct dimensional necessities. The customization procedure entails adapting the aluminum coils' thickness and width to align with the customer's particular requirements. Achieving this objective involves employing diverse techniques, such as rolling, slitting, or cutting the coils in order to achieve the desired dimensions. Furthermore, the customization process may also encompass supplementary alterations such as surface treatments or coatings, contingent upon the application's specific demands.

- Q: Can aluminum coils be used for HVAC ducting?

- Yes, aluminum coils can be used for HVAC ducting. Aluminum is a popular choice for ducting due to its lightweight nature, corrosion resistance, and ability to efficiently transfer heat. It is commonly used in both residential and commercial HVAC systems.

- Q: Are aluminum coils suitable for signage and advertising applications?

- Yes, aluminum coils are suitable for signage and advertising applications. Aluminum is a highly versatile material that offers several advantages for these purposes. First, aluminum is lightweight, making it easy to handle and install. This is especially beneficial for large-scale signage or advertising displays. Second, aluminum is highly durable and resistant to corrosion, ensuring that the signage or advertising materials will withstand the elements and maintain their appearance over time. Additionally, aluminum can be easily fabricated and customized to meet specific design requirements, allowing for creativity and flexibility in signage and advertising applications. Moreover, aluminum is a sustainable material that is recyclable, making it an environmentally friendly choice for signage and advertising projects. Overall, the characteristics of aluminum coils make them an ideal option for signage and advertising applications.

- Q: What are the weight savings achieved by using aluminum coils?

- The weight savings achieved by using aluminum coils can vary depending on the specific application, but generally speaking, aluminum coils are significantly lighter than traditional materials such as steel. On average, aluminum coils can provide weight savings of around 50% or more compared to steel coils. This weight reduction is especially beneficial in industries like automotive, aerospace, and construction, where lighter materials can contribute to improved fuel efficiency, increased load capacity, and enhanced overall performance.

Send your message to us

Customized Aluminum Coils - Mill Finished Aluminium Coil AA8079 Temper H24

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords