5052 Mill Finish Mirror Aluminum Coil for Channel Letter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Mirror Aluminium Coil for Channel Letter

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Mill Finish Mirror Aluminium Coil for Channel Letter

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PVDF Painted Aluminum Coil Competitive Price and BEST Manufacture and factor

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

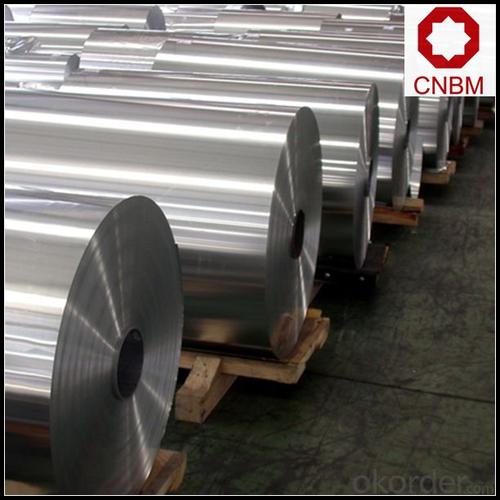

5. Image of Mill Finish Mirror Aluminium Coil for Channel Letter

6. Package and shipping of Mill Finish Mirror Aluminium Coil for Channel Letter

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the role of aluminum coils in the construction of power plants?

- Aluminum coils play a crucial role in the construction of power plants, especially in the cooling systems. The main purpose of these coils is to facilitate heat transfer and maintain efficient cooling within the power plant. Power plants generate a significant amount of heat during the process of converting fuel or other energy sources into electricity. To prevent overheating and ensure optimal performance, cooling systems are installed to dissipate this excess heat. Aluminum coils are a key component of these cooling systems. The aluminum coils are typically used in the construction of air-cooled condensers and evaporators, which are integral parts of the cooling systems. These coils allow for the transfer of heat from the plant's equipment to the surrounding air. They are designed to efficiently transfer and dissipate heat by utilizing the high thermal conductivity of aluminum. The use of aluminum coils offers several advantages in power plant construction. Firstly, aluminum is a lightweight material, making it easier to handle and install in large-scale power plants. This helps reduce construction time and costs. Additionally, aluminum is highly resistant to corrosion, ensuring the longevity and durability of the coils even in harsh operating conditions. Furthermore, aluminum coils provide excellent heat transfer capabilities. They have a high thermal conductivity, meaning they can efficiently transfer heat from the power plant equipment to the cooling medium, typically air. This allows the power plant to maintain stable operating temperatures and prevent any equipment failures or performance issues caused by excessive heat buildup. Overall, aluminum coils are essential components in power plant construction, primarily in the cooling systems. They enable efficient heat transfer, promote optimal cooling, and contribute to the overall performance and reliability of the power plant.

- Q: What are the safety precautions required when handling aluminum coils?

- To ensure the safety of individuals and minimize the risk of accidents, it is important to adhere to certain safety precautions when dealing with aluminum coils. 1. Wearing the appropriate Personal Protective Equipment (PPE) is essential. This includes safety glasses or goggles, gloves, and steel-toed boots. These protective items safeguard against injuries caused by sharp edges or flying metal particles. 2. To avoid strains or back injuries, it is important to employ proper lifting techniques when handling heavy aluminum coils. Lift with your legs, not your back, and utilize lifting aids or equipment when necessary. 3. Proper storage and handling of aluminum coils are crucial. Store them in a well-ventilated area that is free from excessive heat or moisture. It is imperative to stack them securely to prevent injury from falling or rolling coils. 4. Fire prevention measures are vital due to the high flammability of aluminum in the form of fine powder or shavings. Keep the working area clean and free from combustible materials. Smoking or open flames should be strictly prohibited in the vicinity. 5. Be cautious of sharp edges on aluminum coils, as they can cause cuts or lacerations. Handle the coils with care and use appropriate tools or equipment when cutting or shaping them to minimize the risk of injury. 6. Provide proper training and education to all individuals involved in handling aluminum coils. This includes understanding the properties of the material, safe handling techniques, and emergency procedures in case of accidents or spills. 7. Be aware of potential chemical hazards associated with coatings or treatments on aluminum coils. Follow the appropriate safety procedures when handling or working with them. By adhering to these safety precautions, the risk of accidents, injuries, and potential hazards can be significantly reduced when handling aluminum coils. Prioritizing safety and ensuring that all employees are trained and equipped with the necessary knowledge and protective gear is crucial.

- Q: How do aluminum coils contribute to the fire resistance of products?

- Aluminum coils contribute to the fire resistance of products in several ways. Firstly, aluminum has a high melting point, which means that it can withstand high temperatures before it starts to deform or melt. This property is crucial in preventing the spread of fire as it helps to maintain the structural integrity of the product, limiting the fire's ability to penetrate or weaken it. Additionally, aluminum has excellent thermal conductivity, meaning it can efficiently dissipate heat. This characteristic plays a crucial role in fire resistance as it helps to cool down the surrounding area, minimizing the risk of ignition or combustion of nearby materials. By quickly transferring heat away from the source, aluminum coils can prevent the fire from spreading or escalating. Moreover, aluminum is non-combustible, which means it does not burn or support combustion. This property is vital in fire resistance as it prevents the aluminum coils from adding fuel to the fire. Instead, aluminum acts as a barrier, preventing the flames from reaching other flammable materials and reducing the overall fire hazard. Furthermore, aluminum is resistant to corrosion, which enables the coils to maintain their structural integrity over time, even in high humidity or corrosive environments. This durability is crucial as it ensures that the fire resistance properties of products remain intact, providing long-lasting protection against fire hazards. Overall, aluminum coils contribute to the fire resistance of products through their high melting point, excellent thermal conductivity, non-combustible nature, and resistance to corrosion. These properties work together to limit the spread of fire, dissipate heat efficiently, prevent the addition of fuel to the fire, and maintain the structural integrity of the product, ultimately enhancing its fire resistance capabilities.

- Q: What is the difference between aluminum coils and aluminum sheets?

- Aluminum coils and aluminum sheets share the same material, aluminum, but they have distinct characteristics. Firstly, their form and shape differ significantly. Aluminum coils are elongated and wound into a coil shape. They find wide application in construction, automotive, and HVAC industries for purposes such as roofing, insulation, and air conditioning systems. In contrast, aluminum sheets are flat and come in various sizes and thicknesses. They are commonly utilized in aerospace, transportation, and packaging industries for aircraft parts, automotive body panels, and food packaging. Additionally, their manufacturing processes are distinct. Aluminum coils are produced using continuous casting, where molten aluminum is poured into a mold and cooled to solidify into a coil. This technique allows for the creation of long, continuous coils. Conversely, aluminum sheets are typically manufactured through a rolling process. The aluminum is passed through a series of rollers that gradually reduce its thickness until the desired sheet thickness is achieved. Consequently, this method enables the production of flat sheets with specific thicknesses. Furthermore, the applications of aluminum coils and sheets also differ. Due to their coil shape, aluminum coils are suitable for applications that require long, continuous lengths like roofing or HVAC systems. On the other hand, the flat shape of aluminum sheets makes them ideal for applications that necessitate a flat surface, such as panel or component manufacturing. To summarize, the main distinctions between aluminum coils and aluminum sheets lie in their form, manufacturing process, and applications. Coils are elongated pieces created through continuous casting, while sheets are flat pieces produced through rolling. The choice between coils and sheets depends on the specific requirements of the application at hand.

- Q: What are the pros and cons of utilizing aluminum coils in storage applications?

- <p>Aluminum coils offer several advantages for storage, including high durability, corrosion resistance, and lightweight properties which make them easy to handle. They are also recyclable and have good thermal conductivity, which can be beneficial in temperature-controlled environments. However, there are downsides such as higher initial costs compared to some other materials and potential for denting or damage if not properly handled. Additionally, while aluminum is generally non-magnetic, it can be attracted to strong magnets, which might be a consideration in certain storage scenarios.</p>

- Q: How do aluminum coils contribute to fire safety?

- Aluminum coils contribute to fire safety in various ways. First and foremost, aluminum is a non-combustible material, meaning it does not burn or support combustion. This makes it an excellent choice for applications where fire safety is paramount, such as in the construction industry. Aluminum coils are commonly used in the manufacturing of fire-resistant barriers and protective claddings. These barriers act as a shield, preventing the spread of flames and heat between different areas of a building. By containing the fire to its origin and preventing it from spreading, aluminum coils play a crucial role in limiting the damage caused by fires and ensuring the safety of occupants. Furthermore, aluminum coils are often used in the production of fire-resistant doors, windows, and curtain walls. These components are designed to withstand high temperatures and provide an effective barrier against the spread of fire and smoke. By using aluminum coils as the base material for these products, they can offer enhanced fire protection and help to prevent the rapid spread of flames in the event of a fire. In addition to being non-combustible, aluminum is also a highly conductive material. This property allows it to quickly dissipate heat, reducing the risk of ignition and minimizing the potential for fire accidents. Aluminum coils are often incorporated into heat exchange systems, such as HVAC units and refrigeration systems, where their thermal conductivity helps to regulate temperature and prevent overheating, thus reducing the risk of fire. Overall, aluminum coils contribute to fire safety by being non-combustible, acting as fire-resistant barriers, and being used in the production of fire-resistant doors and windows. Their ability to dissipate heat quickly also helps to minimize the risk of fire accidents. By utilizing aluminum coils in various fire safety applications, we can enhance the protection of buildings and ensure the safety of occupants in the event of a fire.

- Q: Are aluminum coils suitable for solar panel applications?

- Solar panel applications can benefit from the use of aluminum coils. This lightweight and highly conductive material offers several advantages. Firstly, aluminum coils effectively transfer and dissipate heat, playing a crucial role in maintaining solar panel efficiency and lifespan. By reducing the temperature of solar cells, aluminum's excellent thermal conductivity helps prevent overheating and potential damage. Furthermore, aluminum coils exhibit high resistance to corrosion, making them an ideal choice for outdoor solar panel installations. Given the exposure to various weather conditions like rain, snow, and humidity, solar panels are prone to corrosion and degradation. However, aluminum's natural oxide layer acts as a protective barrier, ensuring corrosion prevention and enhancing the durability of solar panels. Moreover, aluminum is a cost-effective material that is readily available and easy to manufacture. Additionally, its lightweight nature simplifies the transportation and installation of solar panels, resulting in reduced overall costs. To summarize, aluminum coils are a suitable option for solar panel applications due to their exceptional thermal conductivity, resistance to corrosion, durability, and cost-effectiveness.

- Q: im doing an a level physics presentation on aluminium and im trying to compare aluminium and copper in electricity pylons.i know that copper will have a better conductance than aluminium becasue it has a lower resitivity but i need to come up with a calculation to prove why aluminium is better for use in electricity pylons? i know its down to aluminium being more lightweight than copper and also much cheaper. But im not sure how to create an calculation to show this?:) any help is greatly appreciated

- Copper has lower resistance per unit volume, ie, a 1 cm diameter copper wire has less resistance than a 1 cm aluminum wire. BUT, aluminum is much lighter than Cu for the same diameter. If you used an aluminum wire that weighs the same as the 1 cm diameter copper wire, it would have LOWER resistance. And that is why aluminum is used in power transmission, and also in aircraft, where weight is important. to do this you calculate density resistivity which is (resistivity x density). Here is a partial table: Al 28.2e-9 Ω-m * 2700 kg/m? = 76e-6 Ω-kg/m? Cu 17.2e-9 Ω-m * 8960 kg/m? = 154e-6 Ω-kg/m? Ag 15.9e-9 Ω-m * 10500 kg/m? = 167e-6 Ω-kg/m? Au 22.14e-9 Ω-m * 19300 kg/m? = 427e-6 Ω-kg/m? Zn 68e-9 Ω-m * 7130 kg/m? = 485-6 Ω-kg/m? Fe 100e-9 Ω-m * 7870 kg/m? = 787e-6 Ω-kg/m? Note that Al is half that of Cu.

- Q: Can aluminum coils be used for automotive body panels?

- Yes, aluminum coils can indeed be used for automotive body panels. In fact, aluminum is becoming increasingly popular in the automotive industry due to its many advantages. Aluminum is lightweight, which can contribute to improved fuel efficiency and overall performance of the vehicle. Additionally, aluminum has excellent corrosion resistance properties, making it a durable choice for automotive body panels. Moreover, aluminum can be easily formed and molded, allowing for intricate designs and better aerodynamics. Overall, the use of aluminum coils for automotive body panels is a viable option that offers numerous benefits.

- Q: Can aluminum coils be used for signage and display applications?

- Yes, aluminum coils can be used for signage and display applications. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion, making it an ideal choice for various signage and display purposes. Its flexibility allows for easy shaping and customization, while its smooth surface provides a perfect canvas for printing graphics and designs. Additionally, aluminum coils can be easily mounted, making them suitable for both indoor and outdoor signage and displays.

Send your message to us

5052 Mill Finish Mirror Aluminum Coil for Channel Letter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords