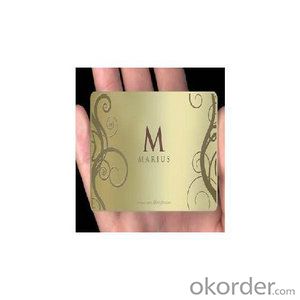

metal business cards wholesale good quality

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1: Very exquisite products

2: OEM/ODM is welcome

3: Definitely new high quality material

4. Factory price

Card designs are the front line image of your business. And since most of us will judge a business by their image (consciously or unconsciously), it is imperative that your business

card portrays professionalism and high quality.

Specifications:

Product type | metal card

|

Material | stainless steel, copper or as customer request

|

Size | 86*54mm or customized

|

Thickness | 0.2mm,0.3mm,0.5mm, 0.76mm,0.82mm or customized

|

Logo | can be Stamped, Enamel, Printed, Engraved, Embossed or customized

|

Available crafts | magnetic stripe, embossing number, signature panel, photo, barcode, hot foil stamping with gold/silver color, scratch-off panel, serial number thermal printing, hole punching, UV printing, laser engraving etc.

|

Lead time | 7-15 days(depend on quantity and personalization craft work)

|

Payment term | pay by T/T, Western Union or Paypal. 50% deposit of the total payment before bulk production and left payment before left factory. (We will take photos after finishing the goods to make sure quality)

|

Samples | 1. Samples is free if just send sample cards we made before for you to test quality.

|

2. If make sample according to your artwork, you will request to pay sample cost.

| |

Package details | 500pcs per inner box with shrink wrap 2000pcs per carton (carton size: 21.5cm*14cm*49cm)

|

Application | public transportation, access management,even ticketing, gaming identity, club, visiting, advertising, retail shop, super market, medical care, bank, parking, school etc |

Weight | 11.6kg per carton(carton size:21.5cm*14cm*49cm)

|

Certificate | ISO 9001-2008

|

- Q: What are the allowable quantity differences in printed packaging materials?

- The ink thickness, three-dimensional sense of common offset and letterpress 5 microns to about 12 microns in gravure printing, flexo printing ink layer (aniline) is 10 microns thick, and the wire net printing ink thickness than the ink layer thickness is generally up to about 30 microns. Thick screen printing special printed circuit board, ink film thickness of up to 1000 microns. Foam ink printing Braille, foaming layer thickness of up to 300 microns. Screen printing ink layer thickness, printing texture rich, three-dimensional feeling strong, this is other printing methods can not match. Screen printing can not only print in monochrome, but also capture and screen color printing.

- Q: What's the printing process for PC material? Is the print content on PC or other surfaces?

- Roll material, screen printing or rotary printing (relatively few, only for thickness below 0.125MM), printing the same as above.

- Q: Carton printing process and materials

- Art paper gravure composite carton process, when the production of large quantities, without film, and requires good printing effect, low cost, you can use this process. This process is to use paper gravure printing machine printing thin coated paper, and then the printed coated paper and ordinary slag paper board or cardboard composite as a whole, carton paper, and then mounted on the carton forming normal.The process is characterized by:(1) the cost of making cartons is low. The main reason for the cost reduction is that the white board is changed into low weight coated paper, which is combined with cheap carton paper to reduce material cost.(2) beautifully printed. The gravure printing effect of paper is very exquisite.(3) gravure printing process is more complicated, and the cost is high, it is not suitable for printing, often revised carton products.(4) the operation and control methods of the printing process, such as paper compounding and box making, should be carefully explored and continuously accumulated and reasonably implemented. Otherwise, the waste rate will be easily increased.

- Q: What are the materials used in screen printing?

- Divided into printed screen and printed material, screen according to different processes are divided into water-based and solvent based, printed material according to different substrate is divided into ink and ink

Send your message to us

metal business cards wholesale good quality

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords