18mm Black Film Faced Tongue and Groove Plywood with Melamine Glue

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

film faced plywood manufacturers

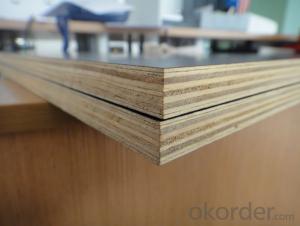

1.Size: 1220 *2440mm

2.Thickness: 18mm

3.Core: hardwood

4.Glue: MR or E1

Description

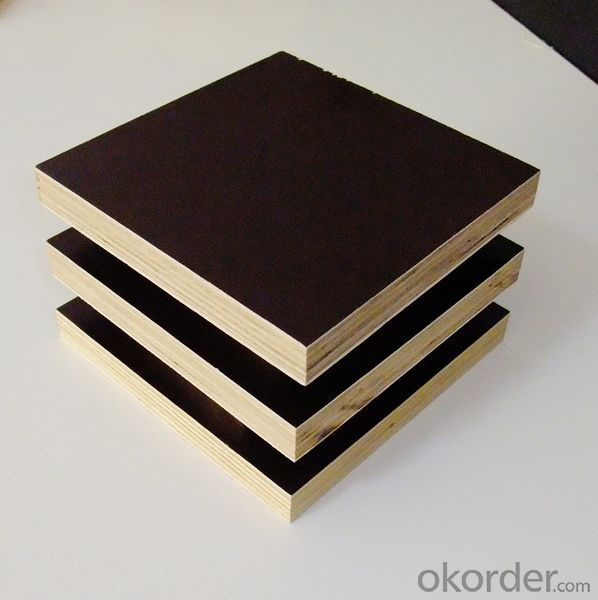

| Name | Film faced plywood,formwork plywood,shuttering plywood,marine plywood |

Size | 1.Small sizes:915x2135mm,1200x1800mm,1525x1525mm 2.Standard sizes:1200X2400mm,1220x2440mm 3.Big size:1250x2500mm |

Thickness | 12,15,16,17,18,20,21,25,27,30mm |

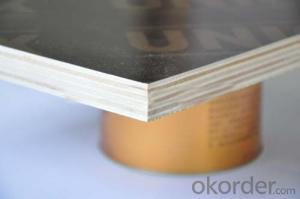

F&B | Black film,chinese brown film,imported brown film,red film,yellow film |

Finish | Smooth,mesh(anti-slip),with or without logo |

Core | Poplar,Hardwood,Eucalyptus,Birch,Pine,Combi and etc |

Glue | MR,melamine WBP,Phenic WBP |

Tolerance | +/-0.5mm |

MOR/MOE | MOR ≥30Mpa;MOE ≥6000Mpa |

Moisture | Less than 14% |

Density | poplar:530~500kgs/cbm,hardwood:600~580kgs/cbm |

Edges | Four edges will be sealed with water-proof paint(red, green or others) |

Usage | Ideal concrete construction materials |

Packing | Inner packing:0.2mm thickness plastic bag Outer packing:pallet with carton and strpped with steel tape |

Delivery | Within 15days after confirm the order |

Load Qty | 1>In container:20GP--8Pallets,40GP--16Pallets,40HC--18Pallets 2>In bulk ship:35sheets/pallet |

| Payment | T/T or L/C at sight |

Features

1. Excellent performance of flame retardant;

2. High chemical stability and Anti-aging;

3. Excellent performance of bonding, coating and machining;

4. Mechanical properties meet the requirements of first-class product to national standard;

5. Non-toxic, non-polluting;

6. Non-corrosive metal;

7. Improved performance of Anti-Mildew;

8. Free formaldehyde content superior to class E1 of GB;

9. Low smoking and the high level of safety.

FAQ

1.free samples are available

2.MOQ is one 40HQ container

3.delivery time 30 days after getting deposit

4.payment term T/T or L/C at sight

- Q: The structure of the plywood at the same time meet two basic principles

- So the plywood is usually three, five, seven odd level layer. The name of each layer of the plywood is: the surface of the board is called the table, the inner plate is called the core board;

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- partition panel, the board formed by drilling a variety of patterns, the surface spraying a variety of coatings, decorative effect is better

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides

- Q: Judging wood is the standard for plywood

- If you can identify the type of wood used by your own furniture, it will help you identify the true value of the furniture

- Q: What are the defects in plywood material?

- holes In the process of shipment, holes are caused by hooks and tools for workers' picking.

- Q: What is the difference between plywood glue E0E1?

- Melamine gel: moisture-proof, and has a certain resistance to boiling, weather resistance / can be used for outdoor or indoor, but can not often be water immersion.

- Q: Classification of plywood for construction

- if you want to make outdoor use of wood products, you can use E1 (even E0 level) phenolic plasti

- Q: What is the amount of construction works used for this plywood?

- Three types of plywood for moisture-resistant plywood, can be immersed in cold water for a short time, suitable for indoor use at room temperature. For furniture and general construction purposes;

- Q: Why is the plywood commonly used in the singular layer

- and take a vertical put a then put the plastic in the horizontal put a then In the vertical put a piece into a plywood

- Q: What are the types of veneer veneer veneer?

- according to the decorative veneer texture can be divided into radial decorative veneer veneer plywood chord decorative veneer veneer plywood

Send your message to us

18mm Black Film Faced Tongue and Groove Plywood with Melamine Glue

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords