Melamine Faced Particle Board 16mm for Furniture and Decoration

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³ m³

- Supply Capability:

- 10000 CBM/month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

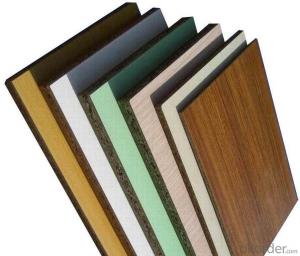

Specifications of Melamine Faced MDF Boards:

Name:Melamine Faced MDF Boards Manufacturer for Furniture and Decoration

Quality standard: GB/T 15102-2006

Size: 1220x2440mm (4'*8')

Thickness: 2.5mm to 25mm or as customised

Formaldehyde emission: E1,E2, E0, Cabon P2

Density: 650kg/m3-820kg/m3

Surface texture: Quality UV lacquered,corner with ABC protecting

Certificate:ISO9001,FSC,

Usage:Widely used for kitchen cabinet,showcase

Packing:Pallet packing or any sea worthy packing

Lead time:10-30 days after done payment

____________________________________________________________________________________________

Features of Melamine Faced MDF Boards:

1:High eco-friendly.low VOC discharge

2:Excellent glossy and mirro effect,surface hardness with 3H which difficult to make scratch

3:Smooth surface easy to clean and durable

4:Moisture-proof, fire-proof,anti-acid and anti-alkali against a variety of disinfector

5:OEM,designed painting would be welcome

__________________________________________________________________________________________

Various Color Choices

Our Factory

- Q: What are the types and usage of interior panels?

- From the board surface texture can be seen: natural wood trim panel is to look texture pattern natural, variability is relatively large, there is no rule. Artificial veneer panel looks texture is basically straight texture, or pattern is particularly regular.

- Q: What is the plate? Is it really environmentally friendly?

- Ordinary melamine plywood has long been in the domestic production, was originally used to do computer desk and other office furniture, mostly monochrome board, including everyone familiar with the "double white" "double gray." With the popularity of furniture in the family, melamine plywood gradually become the first choice for the furniture factory manufacturing materials,

- Q: What is the difference between a melamine plywood and a flat sheet?

- While not causing any pollution to the building, you can strictly limit the amount of harmful gas emissions.

- Q: What are the quality requirements for decorative panels?

- Decorative veneer - Material quality requirements: First, depends on the thickness of the decorative panels have reached the specified thickness (commonly used 1mm 2mm the thickest thickness of 3mm different prices, with the exception is also different) Second, Texture direction or pattern as a whole is not a third to see the decorative panel toughness (the bigger the better) Fourth, look at the surface of the decorative panel is smooth

- Q: Home improvement commonly used plate which?

- Decorative panel technology: the splint as the substrate, the veneer made by the adhesive process. Different types of panels have different uses

- Q: What are the types of wood panel?

- 2. Maple: pattern was obvious water ripples, or was thin stripes. Milky white, elegant color uniformity, high hardness, high shrinkage rate, low strength. Used for solid wood flooring, as well as furniture trim panels.

- Q: What are the advantages of ecological boards and other boards?

- Consumers in the selection of such plate furniture, in addition to taking into account the color and texture satisfaction, but also from several aspects to identify the appearance of quality: whether stains, scratches, indentation, porosity, color gloss is not uniform, there is no Bubbling phenomenon, with or without local paper tear or defect phenomenon and so on. If the phenomenon of veneering cracking or damage, you can use the following methods to repair: first in the damaged place to put a damp cloth, and then put a hot iron on the hot cloth, forcing the moisture into the veneer, so that the veneer becomes tough and difficult Fragmentation. So that you can first clean the old plastic, and then coated with a layer of milk at the grass layer of wood, and then in the loose surface of the negative coated with a layer of new plastic, compaction, to be completely dry glue.

- Q: Do you want to paint the panel, what panel?

- Decorated panels, according to their favorite wood grain selection panel, such as maple, white rubber, ash and so on. Come out better.

- Q: What is the paper for pvc plywood?

- Search the veneer of the paper after three o-melamine glue 2 and a g of some additives after impregnation, that is, three j polyamide impregnated paper.

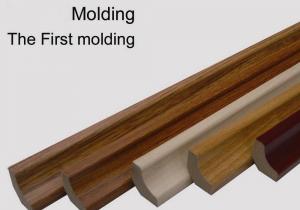

- Q: How many types of wooden lines

- Second, the protective effect, especially in the panel of the mouth of the mouth, if not to protect the line, the future use of the process of the surface of the panel can easily be scratched, affecting the use.

Send your message to us

Melamine Faced Particle Board 16mm for Furniture and Decoration

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³ m³

- Supply Capability:

- 10000 CBM/month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords