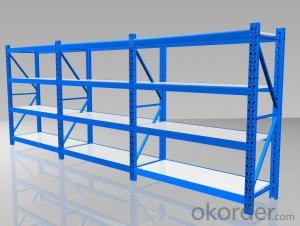

Mediem Sized Pallet Racking Shelving System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

The Medium duty pallet rackging system is used for medium weight goods. It has standard and non standarn type and could be customized design for goods, pallets and etc.

Feature:

· use bean and layer structure

· Height could be adjusted

· Big loading weigh

Images:

Specification:

Size | 2000L*600W*2000H |

Loadging | 200-500 KG |

FAQ:

What is note for purchase?

Pallet size,good weight, warehouse sapce and height, etc.

How is quality guaranteed?

The production use professional roll forming technology and material of steel for production have strict test. The finished product into market are all guaranteed for users

How about the project installation?

Drawing for installation is provided for users. We also could send engineers to users's spot to carry out installation.

- Q: What are the basic principles of warehousing?

- The "warehouse" also known as the warehouse, store items for buildings and facilities, for housing construction, large containers, caves or specific sites, is to store and protect the function of items; "reservoir" said storage for use, storage, storage, delivery and use of means, when applied to tangible items also for storage. "Warehousing" is the act of using a warehouse to store and store items that are not immediately available. In short, warehousing is the act of storing goods in a particular place.

- Q: What are the key functions of warehouse management logistics informatization construction?

- WMS and automatic identification technology are inseparable, with large technology, a dozen focus on enterprise warehouse management research and development, the success of many large domestic enterprises to solve the problem of warehouse management.According to the existing customer database system for analysis, for each product to establish a bar code identification, bar code bar code printer to print the barcode label, resulting in the sequence number, the relevant information should be included in each of the barcode products. (customized by the customer) can include the product name, specifications, quantity, bar code serial number, date of warehousing and date of delivery. ---- initial information collection, EBIG logistics and warehousing management system (WMS)

- Q: The role of warehouse management in Enterprises

- Warehouse management, that is, library management. Warehouse management refers to the warehouse and its inventory management, warehousing system is an indispensable subsystem of the enterprise logistics system. The overall objective of logistics system is to provide customers with satisfactory service at the lowest cost, while the warehouse system plays an important role in it. Storage activities can promote enterprises to improve customer service levels, and enhance the competitiveness of enterprises. Modern warehouse management has changed fundamentally from static management to dynamic management, and has put forward higher requirements for the basic work of warehouse management.

- Q: What are the advantages of automated warehousing and its role in logistics systems?

- Information flow and logistics can not be unified in time. On the one hand, the traditional warehouse is often low level of information technology, resulting in low level of overall logistics management, unable to provide customers with high-quality and flexible logistics services. On the other hand, because of the information flow and logistics can not be unified, resulting in the error costs described above, so that the overall cost of warehousing increased.

- Q: What are the main differences between the electricity supplier warehouse and the traditional warehouse?

- Average order lines are few. Traditional retail logistics has dozens, even more, hundreds of orders line, these goods may be distributed in all corners of the warehouse, according to order picking, warehouse go round to complete order picking. But only a few of the electricity supplier logistics orders, in most cases such as Jingdong, such as dangdang is no more than 10, a few such as shop No. 1 will be between 10 to 20, if still use the traditional retail logistics commonly used to order not picking, picking up for each trip only a few parts need to go a large number of road in the warehouse. A large number of actual combat statistics show that as much as 70% of the time spent in the picking process is on walking. Therefore, it is necessary to design a picking order, and can complete multiple orders at the same time, to improve the efficiency of picking, such as first picking, picking, planting, or picking the same model.

- Q: What's the sea cucumber logistics equipment?

- Sea cucumber is a kind of spiny animal that grows on the bottom rock of the sea or between seaweeds. It is named after its "warm, warm and sufficient ginseng". Sea cucumber as a rarity, its nutritional value is high, the treatment effect of magic, has long been recognized and praised.

- Q: How to classify logistics facilities and equipment is more reasonable and scientific

- Logistics infrastructure mainly includes warehousing, carrying facilities, and computing and information communication equipment.Since human society has surplus production, there is storage, and warehouses are facilities for storing materials. In accordance with different angles, features and signs, the warehouse has its own warehouses, warehouses, public warehouses, bonded warehouses and bonded goods. Warehousing facilities play an important role in the whole logistics process:(1) the function of material storage. Any warehouse has a certain space to accommodate materials. The modern warehouse is not only a place for placing goods, but also a variety of facilities, with moderate storage and maintenance functions.(2) regulating the supply and demand of materials. There is a wide range of linkages between supply and demand as well as considerable complexity. When the supply and demand are unbalanced, the storage of the warehouse can act as a "reservoir" type.(3) regulating the function of material transportation. Transport capacity varies greatly because of the different means of transportation. The transportation contradiction caused by the difference of transportation capacity can be solved by the storage of materials, which is the function of material storage, regulation and transportation.(4) the function of material distribution. In modern logistics, warehouses in developed countries have been changed from original storage to distribution centers. That is to say to warehouse homework material sorting, matching, processing and circulation, in the new requirements, the warehouse has material distribution function.(5) the function of material saving. The role of material saving is indirectly manifested. Because people's production surplus is stored for a certain period of time without waste.

- Q: What are the characteristics of electric power supplies (such as transformers, cables, etc.), mainly in logistics, warehousing and transportation?

- Storage of electric power materials should be prevented from dampness, good rain proof water and moist air intrusion, and electric porcelain equipment should be placed in strict accordance with the requirements, and can not be taken down at will. To prevent collisions and matters should be noted, but also to strengthen ventilation and humidity control and regulation.

- Q: What shelves are there in the logistics equipment?

- Logistics equipment has been applied in every link of logistics. At present, both in the production, warehousing, circulation process of transportation and distribution, logistics center packaging processing, handling, loading and unloading, logistics equipment has been a certain application.Specialized new logistics equipment and new technology, logistics equipment constantly emerging. With the continuous refinement of the logistics sector, with the increasing demand for logistics services to meet customer needs, the new logistics equipment and new technology, logistics equipment continue to emerge. Most of these equipments are specialized in logistics operation of a logistics link, a specialized commodity, a specialized customer's equipment, and its specialization is very high.

- Q: Common equipment for warehouse logistics equipment

- Three dimensional shelf, conveyor equipment, AGV trolley, reciprocating lift, pallet, etc. 134313 dragon 67497 provide reference!

Send your message to us

Mediem Sized Pallet Racking Shelving System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords