USPS Approved Packaging Tape - Masking Tape in Various Colors with Tower Shrink Package

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 200000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Masking Tape In Various Colors

Interior paint masking, silk screening, Light duty packaging, bundling, holding, splicing &Tabbing, and other non-critical applications where a pressure-sensitive tape is needed.

Size of Masking Tape In Various Colors

Paper Core ID: 76mm

Jumbo size: 0.99m x 1800m, 1.22m x 1800m, 1.51m x 1800m

Cut roll size: As per customer's requirement

Cut rolls: Shrink package, placed in cartons, with or without pallet

Packing of Masking Tape In Various Colors

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

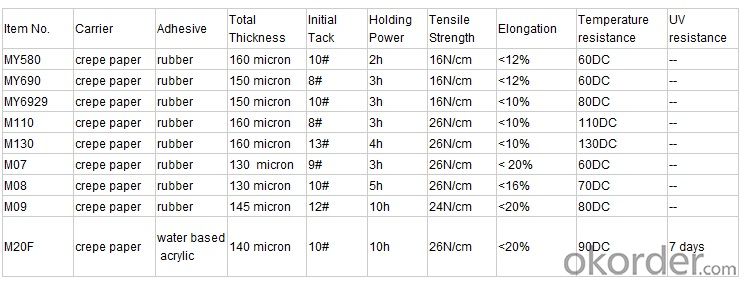

Technical Data of Masking Tape In Various Colors

Picture Show of Masking Tape In Various Colors

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s world wide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferencial shipping channels, with a separate team dealing with shipping.

- Q: How do I prevent packaging tape from wrinkling?

- To prevent packaging tape from wrinkling, there are a few things you can do: 1. Use a tape dispenser: A tape dispenser helps ensure a smooth application of tape, reducing the chances of it wrinkling. It also provides better control while taping, making it easier to keep the tape straight and tight. 2. Apply the tape with tension: When applying the tape, pull it tightly as you stick it down. This helps prevent any slack or loose areas that could cause wrinkling. Be careful not to stretch the tape too much, as it may lose its adhesive properties. 3. Use the right type of tape: Different types of packaging tape have different adhesive properties and thicknesses. Choosing a high-quality tape specifically designed for packaging can help minimize wrinkling. Additionally, consider using a tape with reinforced fibers for added strength and resistance to wrinkling. 4. Ensure a clean surface: Before applying the tape, make sure the surface is free from dust, dirt, or any other debris. These particles can cause the tape to wrinkle or not adhere properly. Clean the surface thoroughly and dry it before taping. 5. Avoid extreme temperatures: Packaging tape can be sensitive to temperature changes, which may lead to wrinkling. Avoid using the tape in extremely cold or hot environments. If possible, store the tape in a controlled temperature area before use. 6. Apply pressure: After applying the tape, run your hand or a roller over it to ensure good adhesion. This helps smoothen out any potential wrinkles or bubbles and ensures that the tape is securely attached. By following these tips, you can significantly reduce the chances of packaging tape wrinkling, resulting in a neater and more secure package.

- Q: Has anyone done a tape cut? What about profit?

- If you sell the home directly, the profit may be higher (but the payback period is longer, and there is no strong capital will be difficult to do). The overall evaluation is not recommended sub cut, direct dealers do better.

- Q: Can packaging tape be used for sealing ceramic items?

- Yes, packaging tape can be used for sealing ceramic items. Packaging tape is designed to be strong and durable, making it suitable for securing and sealing various materials, including ceramics. However, it is important to note that packaging tape may not provide the same level of protection as specialized ceramic sealants or adhesives. If you are looking for a more secure and long-lasting seal, it is recommended to use a ceramic-specific adhesive or sealant that is designed to withstand the unique properties of ceramics, such as temperature changes or moisture exposure.

- Q: Does packaging tape come in different lengths?

- Indeed, packaging tape does come in a variety of lengths. Diverse lengths of packaging tape are accessible to cater to distinct packaging requirements. Standard lengths for packaging tape comprise 55 yards, 110 yards, and 1000 yards, although additional lengths might also be obtainable. The length of the packaging tape you opt for is contingent upon the size and quantity of packages you intend to seal. It is crucial to take into account the required length of packaging tape to guarantee an adequate supply for securely sealing your packages, without the risk of running out.

- Q: How does packaging tape perform on rubber surfaces?

- Rubber surfaces can be effectively secured using packaging tape, which has been designed with adhesive that adheres well to various materials, including rubber. When applied correctly, packaging tape creates a strong bond, ensuring the secure packaging or fastening of materials. It is important to consider that the effectiveness of packaging tape on rubber surfaces may vary depending on the specific type of rubber and the condition of the surface. In certain instances, the tape may not adhere as strongly to certain types of rubber, particularly if the surface is rough or dirty. To achieve optimal adhesion, it is always advisable to clean and dry the rubber surface before applying packaging tape. Additionally, extreme temperatures and moisture can impact the performance of packaging tape on rubber surfaces. Therefore, it is recommended to store and use the tape within the recommended temperature range and avoid exposing it to excessive moisture. In general, packaging tape is a reliable and secure option for bonding materials on most rubber surfaces, making it suitable for packaging and securing purposes.

- Q: Can packaging tape be used for other purposes?

- Packaging tape has a wide range of uses beyond its intended purpose of sealing packages. Its strong adhesive properties and durability make it suitable for various applications. One popular alternative use for packaging tape is organizing and bundling items together. It can be used to sort and secure cables, cords, loose items, or similar objects, effectively keeping them organized. Additionally, it can be used to temporarily attach items like posters or decorations to walls or surfaces without causing any damage. Furthermore, packaging tape is great for crafting and DIY projects. Its adhesive nature allows it to create both temporary and permanent bonds between different materials. It can repair torn papers, create labels or tabs, or even make personalized stickers. Its versatility, available in different widths and lengths, makes it a valuable tool for creative endeavors. Moreover, packaging tape can be used for household fixes and repairs. Its strong adhesive properties can temporarily mend broken items or reinforce weak joints. It can also provide a temporary seal for minor leaks or cracks until a proper repair can be done. In conclusion, packaging tape's strong adhesive properties and versatility make it suitable for various purposes beyond sealing packages. Whether for organizing, crafting, or quick fixes, having packaging tape on hand can be highly useful.

- Q: Can packaging tape be used for sealing plastic shoeboxes?

- Yes, packaging tape can be used for sealing plastic shoeboxes. It provides a strong and secure seal, keeping the contents of the shoeboxes safe and protected.

- Q: Can packaging tape be used for sealing wooden furniture?

- Yes, packaging tape can be used for sealing wooden furniture. While it may not be the most conventional or aesthetically pleasing option, packaging tape can effectively seal gaps or cracks in wooden furniture, preventing dust, moisture, or insects from entering. However, it is important to note that packaging tape is not a long-term solution, as it may not provide the same level of durability or stability as other sealing methods specifically designed for wooden furniture, such as wood glue or epoxy. Therefore, it is recommended to use packaging tape as a temporary fix until a more appropriate sealing method can be applied.

- Q: Are there any specialty packaging tapes for specific applications?

- Indeed, there exists an array of specialty packaging tapes tailored for distinct applications. These tapes are specifically crafted to cater to the diverse needs and demands across various industries. Illustrative instances of specialty packaging tapes encompass: 1. Double-sided tapes: These tapes possess adhesive on both surfaces and are widely employed for mounting purposes, such as affixing posters or signs onto surfaces. 2. Tamper-evident tapes: These tapes produce a discernible mark or pattern upon removal, serving as evidence that the package has been tampered with. They are frequently utilized for securely sealing sensitive or valuable items during transportation. 3. Filament tapes: These tapes integrate fiberglass strands, imparting them with remarkable tensile strength. They are commonly employed for bundling weighty items or reinforcing packages that necessitate augmented sturdiness. 4. Masking tapes: These tapes offer a weak adhesive force and can be effortlessly detached without leaving residue or causing surface damage. They are frequently employed for masking off areas during painting or for temporary holding applications. 5. Printed tapes: These tapes can be customized with specific messages, logos, or branding in order to enhance the presentation of packages and foster brand recognition. 6. Cold temperature tapes: These tapes are engineered to endure exceedingly low temperatures and are frequently employed in cold storage facilities or for shipping goods that necessitate refrigeration. 7. Hazard warning tapes: These tapes boast vibrant hues and feature printed warning messages or symbols. They are often employed to mark hazardous areas or indicate potential dangers. These aforementioned examples merely scratch the surface of the extensive variety of specialty packaging tapes accessible in the market. Each tape is meticulously designed to meet distinct requirements, guaranteeing the secure and dependable packaging of diverse products or materials across various industries.

- Q: Can packaging tape be used for sealing household or kitchen items?

- Certainly! Packaging tape is indeed suitable for sealing household or kitchen items. With its versatility as an adhesive tape, it is widely employed for sealing cardboard boxes. However, it can also serve the purpose of sealing numerous items found in the household or kitchen. Whether you require sealing food containers, plastic bags, or even small appliances, packaging tape guarantees a robust and reliable seal. To optimize its adhesive strength, it is crucial to ensure that the surface is both clean and dry prior to applying the tape.

Send your message to us

USPS Approved Packaging Tape - Masking Tape in Various Colors with Tower Shrink Package

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 200000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords