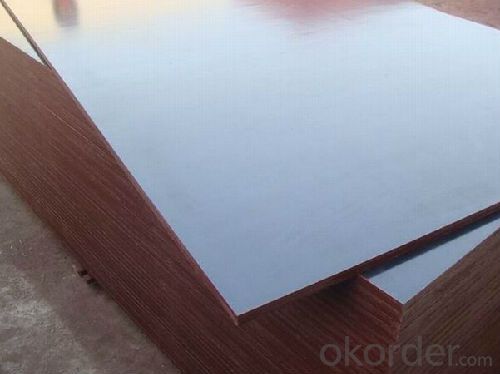

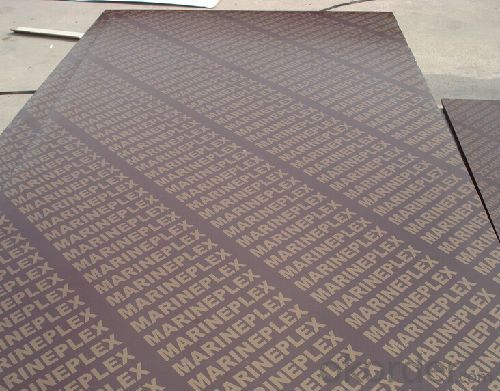

1/4 Plywood 4x8 Marine Plywood with First Class Quality

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 6000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

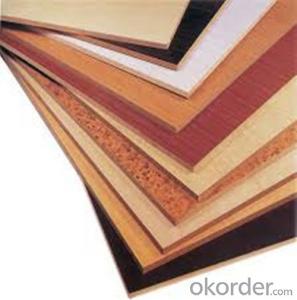

Plywood Introduction :

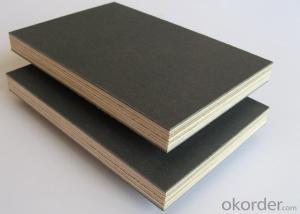

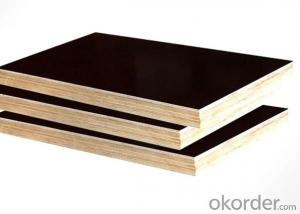

Plywood is with film faced , it is widely used in construction formwork system , it is the direct close with concrete .To make sure flat concrete surface, we ask the plywood better surface and long using lifetime .It can be with brown film and black film and plastic film.

Feature:

1.High bending strength

2.Strong nail holding

3.Moisture-proof and easy work

4.Tight construction and high strength

Specification:

Film | Chinese film 180-240g/m2 | |

Core | birch,poplar, hardwood ,combined or others | |

Grade | A/A or requested by customers | |

Glue | WBP,MR,Melamine(waterproof) | |

Size(mm) | 2440X1220, 2500X1250, 3000x1500 | |

Thickness(mm) | 6-27mm | 1/4inch(6-6.5mm) |

1/2inch(12-12.7mm) | ||

5/8inch(15-16mm) | ||

3/4inch(18-19mm) | ||

Moisture | ≤10% | |

Thickness tolerance | ≤ 6mm | +/-0.2mm to 0.3mm |

6-27mm | +/- 0.5mm | |

Packing | For transportation of Ocean and Land, Inside Pallet is wrapped with 0.2mm plastic bag, Steel strip or PVC for strength, More than 2mm plywood sheet or hard paper covering all the sides left, right,top and bottom. | |

Quantity | 20GP | 8 pallets/21M3 |

40GP | 16 pallets/42M3 | |

40HC | 18 pallets/53M3 | |

Usage | Usage Adequate for concrete forming for construction | |

Min Order | 1x20'ft container | |

Payment | T/T or L/C at sight | |

Delivery time | Within 20days after receiving deposit or Original L/C at sight | |

- Q: What is the general use of plywood in decoration works?

- Plywood is one of the common materials for furniture, one of the three panels of man-made board, but also for aircraft, ships, trains, cars, construction and packaging materials

- Q: What is the composition of the plywood?

- Plywood usually refers to the plywood or multi-layer board, that is, with the same thickness of two or more layers of veneer plus glue from high temperature suppression

- Q: Class I resistant weather plywood Class II water resistant plywood

- Hard fiber board sound absorption, waterproof performance is good, durable, easy constructio

- Q: How do you choose plywood in plywood production?

- But should be described in the name of the product, such as "cedar veneer plywood", or "fir slices plywood", or "cherry wood trim".

- Q: How is the current market outlook for plywood?

- Although China plywood has developed rapidly, but still encounter the EU and other importing countries of the anti-dumping complaints

- Q: Wood board, plywood, MDF What is the difference

- The quality of the two panels is different, the quality is better called the panel, the other side is the backplane.

- Q: The Decorative veneer veneer plywood grade classification

- To remind manufacturers and other forms of consumer do not meet the requirements of China's decorative veneer veneer plywood standards

- Q: Now the market prospects for plywood

- regulate export order. With the expansion of China's infrastructure construction and the strengthening of the development of the Midwest, plywood market has great potential.

- Q: What is a joinery board?

- Blockboard core board should be the same species or similar properties of the tree species, water content of 6 to 12%. Core width is not greater than three times the thickness, do not allow a larger crack, holes and so on

Send your message to us

1/4 Plywood 4x8 Marine Plywood with First Class Quality

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 6000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords