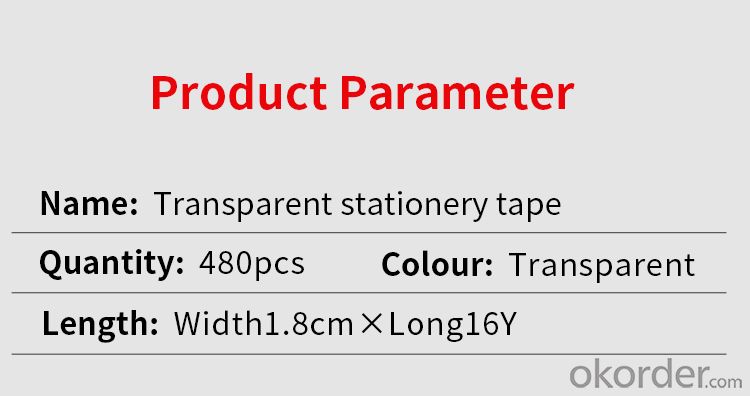

Manuli Packaging Tape 1.8cmx25y (480 Rolls)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 480 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stationery tape: 1.8cmX25y (480 rolls), material: OPP, the finished product will be shipped after pasting the product label (the label artwork is provided by our company)

Q&A

Q:Does our product support customization?

A:Our products can support customization, but there are requirements for the quantity, you can contact us for details.

Q:When you call or send a quotation request, what information do you need to provide?

A:Your needs for the product, and what you want to know in detail.

- Q: How does packaging tape perform on oily or greasy surfaces?

- Packaging tape generally does not perform well on oily or greasy surfaces. The adhesive on packaging tape is designed to bond to clean and dry surfaces, so when applied to oily or greasy surfaces, the tape may struggle to stick securely. The oil or grease can act as a barrier, preventing the adhesive from effectively bonding to the surface. As a result, there is a higher probability of the tape peeling or coming loose. To ensure proper adhesion on oily or greasy surfaces, it is recommended to thoroughly clean and degrease the surface before applying packaging tape. Using a degreasing agent or detergent can help remove the oil or grease, allowing the tape to adhere more effectively. Additionally, selecting a high-quality packaging tape with a strong adhesive can also help overcome the challenges posed by oily or greasy surfaces.

- Q: Can packaging tape be used for bundling items together?

- Yes, packaging tape can be used for bundling items together.

- Q: Does packaging tape come in different allergen-free options?

- Yes, packaging tape is available in various allergen-free options. Many manufacturers offer packaging tapes that are specifically designed to be hypoallergenic and suitable for individuals with allergies or sensitivities. These tapes are typically free from common allergens such as latex, gluten, and certain chemical irritants. It is important to check the product description or contact the manufacturer to ensure that the packaging tape meets your specific allergen-free requirements.

- Q: Does packaging tape come in different odor-free options?

- Yes, packaging tape does come in different odor-free options. Many manufacturers offer packaging tape that is specifically designed to be odor-free, making it suitable for use in sensitive environments or for individuals who may have allergies or sensitivities to certain scents. These odor-free options are typically made from materials that do not emit any strong smells or fragrances, ensuring a neutral and pleasant packaging experience. When purchasing packaging tape, it is always a good idea to check the product description or labeling to see if it is specifically mentioned as odor-free.

- Q: Does packaging tape have a specific shelf life?

- Indeed, there is a designated lifespan for packaging tape. The duration of this lifespan fluctuates depending on the type and caliber of the tape. In general, the majority of packaging tapes possess a shelf life spanning from one to two years. Nevertheless, this lifespan can be elongated or abbreviated due to certain factors such as storage circumstances and exposure to sunlight or extreme temperatures. It is crucial to consult the manufacturer's guidelines or packaging for any explicit instructions regarding the tape's shelf life. To guarantee optimal performance and adhesive potency, it is advisable to employ packaging tape within its designated shelf life.

- Q: Can packaging tape be used for sealing plastic folders?

- Yes, packaging tape can be used for sealing plastic folders. Packaging tape is designed to be strong and adhesive, making it suitable for securing and sealing various materials including plastic folders. It can help keep the contents of the folder secure and protected. However, it is important to ensure that the tape is applied properly and securely to ensure a tight seal. Additionally, it is recommended to use a clear packaging tape that will not obstruct the visibility of the folder's contents.

- Q: Is packaging tape safe to use on plastic cutting mats?

- Before using packaging tape on plastic cutting mats, it is important to take a few factors into consideration. Firstly, make sure that the cutting mat is made of a durable and food-safe material. Some lower quality mats may get scratched or torn when tape is applied, so it is advisable to check the manufacturer's recommendations. Secondly, think about why you want to use packaging tape on the cutting mat. If it is for temporary storage or transportation, packaging tape can provide a secure seal. However, if the tape will come into direct contact with food or be used during food preparation, it is best to avoid using packaging tape. The adhesive residue from the tape could transfer onto the food or contaminate the cutting surface, which could be a health risk. In such cases, it is better to use food-grade or specialized tape that is specifically designed for cutting mats or food preparation surfaces. In conclusion, although packaging tape can be safe to use on plastic cutting mats, it is crucial to consider the quality of the mat, the purpose of using the tape, and potential food safety concerns. Always prioritize the safety and hygiene of your food preparation surfaces by choosing the appropriate tape.

- Q: Are there any specialty packaging tapes for specific applications?

- Yes, there are specialty packaging tapes available for specific applications. These tapes are designed to cater to specific needs and requirements in various industries. Some examples of specialty packaging tapes include: 1. Double-sided tapes: These tapes have adhesive on both sides and are commonly used for mounting purposes, such as attaching posters or signs to surfaces. 2. Tamper-evident tapes: These tapes leave a visible mark or pattern when removed, indicating that the package has been tampered with. They are commonly used for sealing sensitive or valuable items during transportation. 3. Filament tapes: These tapes have fiberglass strands embedded in them, providing high tensile strength. They are commonly used for bundling heavy items or reinforcing packages that require extra strength. 4. Masking tapes: These tapes have low adhesive strength and are easily removable without leaving residue or damaging surfaces. They are commonly used for masking off areas during painting or for temporary holding applications. 5. Printed tapes: These tapes can be customized with specific messages, logos, or branding to enhance the presentation of packages and promote brand awareness. 6. Cold temperature tapes: These tapes are designed to withstand extremely low temperatures and are commonly used in cold storage facilities or for shipping goods that require refrigeration. 7. Hazard warning tapes: These tapes are brightly colored and have warning messages or symbols printed on them. They are commonly used to mark hazardous areas or indicate potential dangers. These are just a few examples of the many specialty packaging tapes available in the market. Each tape is designed to meet specific requirements, ensuring the safe and secure packaging of different products or materials in various industries.

- Q: Is packaging tape resistant to chemicals?

- Packaging tape is typically resistant to a wide range of chemicals. Most packaging tapes are made from materials such as polypropylene or polyvinyl chloride (PVC), which are known for their chemical resistance properties. These materials have the ability to withstand exposure to various chemicals, including solvents, acids, and bases. However, it is important to note that the level of chemical resistance can vary depending on the specific type and quality of packaging tape being used. Some tapes may have a higher resistance to chemicals than others. Additionally, the duration and intensity of chemical exposure can also affect the tape's resistance. To ensure the tape's chemical resistance, it is recommended to check the manufacturer's specifications and guidelines regarding chemical compatibility. If you are dealing with particularly harsh chemicals or specialized applications, it may be necessary to seek out specific types of packaging tapes that are specifically designed for those conditions.

- Q: Can packaging tape be used for securing cables or cords?

- Yes, packaging tape can be used for securing cables or cords. While it may not be the most ideal choice, especially for long-term or heavy-duty applications, packaging tape can temporarily secure cables or cords together. It can help prevent them from tangling or getting in the way, especially during transportation or storage. However, it is important to note that packaging tape is not designed specifically for cable management, and as such, it may not provide the same level of durability or flexibility as specialized cable ties or straps. For more permanent or heavy-duty cable management, it is recommended to use products specifically designed for that purpose.

Send your message to us

Manuli Packaging Tape 1.8cmx25y (480 Rolls)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 480 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords