Rock Wool Reinforced High Quality Industrial Furnace Used High Chrome Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | Material: | chrome |

| SiO2 Content (%): | none | Al2O3 Content (%): | 0-80% | MgO Content (%): | none |

| CaO Content (%): | none | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 12-93% |

| SiC Content (%): | none | Model Number: | high chrome refractory brick | Brand Name: | Lepe |

| Cr2O3 %: | more than 12%,30%,60%,86%,93% | Al2O3 %: | o, less than 38% or 68%, more than 80% | Shape & size: | customizable |

| Application: | High chrome refractory brick for furnace key part, lining ,etc |

Packaging & Delivery

| Packaging Details: | wooden box pakcing, standard export packing |

| Delivery Detail: | 15-25 days after the receiving the payment |

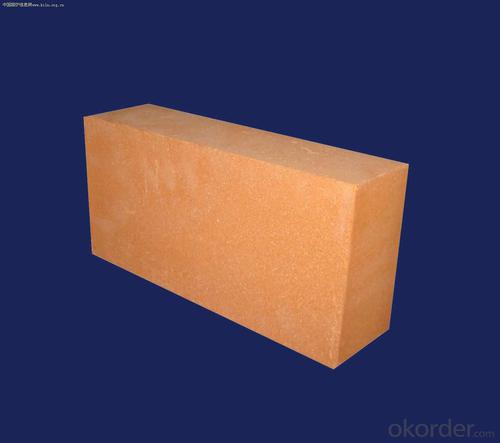

High quality industrial furnace used high chrome refractory brick

High chrome refractory brick, based on corundum and fused chromium oxide as the main raw materials, with micro-powder and other additives, through mixing, molding and drying, are made by baking at high temperature in shuttle kiln.

It is characterized by high temperature, good corrosion resistance, thermal shock and bulk stability under high temperature etc .

Parameter

| Item | High Cr2O3 | Middle chrome | Chrome-Corundum | Chrome-Corundum | Chrome-Corundum |

| brick | brick | brick | brick | brick | |

| Cr2O3 % | ≥93 | ≥86 | ≥60 | ≥30 | ≥12 |

| Al2O3 % | -- | -- | ≤38 | ≤68 | ≥80 |

| Fe2O3 % | -- | -- | ≤0.2 | ≤0.2 | ≤0.5 |

| Apparent porosity | ≤17 | ≤17 | ≤14 | ≤16 | ≤18 |

| Bulk density | ≥4.3 | ≥4.2 | ≥3.63 | ≥3.53 | ≥3.3 |

| Cold crushing strengh | ≥100 | ≥100 | ≥130 | ≥130 | ≥120 |

| Refractoriness under load | ≥1680 | ≥1670 | ≥1700 | ≥1700 | ≥1700 |

| Reheating linear change rate | ±0.2 | ±0.2 | ±0.2 | ±0.2 | ±0.2 |

Application

High chrome refractory brick is mainly used in the key parts of the furnaces for coal chemical industry, chemical industrial, alkali-free glass fiber and garbage incinerator, etc.

It also used for the linings of carbon shoot furnace and copper smelting furnace, the skid rail molten pool of glass furnaces, and tapping platform of rolling mill furnace.

- Q: What does the rock wool board look like?

- The initial development of Hebei Langfang Dacheng in the building is a common type of application for industrial buildings should be consistent with "building insulation materials, the type of application and basic requirements"

- Q: What role does dolomite play in rock wool products?

- What role does dolomite play in rock wool products?

- Q: Rock wool products are divided into several categories

- In the rock wool by adding special adhesive can be processed into rock wool board, rock wool stave, rock wool insulation and other products, as the building insulation, insulation, cold, sound-absorbing material

- Q: How to judge the quality of rock wool

- Burning performance: Combustion performance refers to all the physical and chemical changes that occur when the building material is burned or in case of fire. This performance is caused by the fire and flame propagation of the material surface, heat, smoke, carbonization, weight loss, and toxicity And other characteristics to measure. The burning performance of the products of rock wool products is zero.

- Q: The difference between rock wool and rock wool

- Flexible, medium strength rock wool board: for building walls / roof insulation, fire, sound, such as curtain wall, wall partitions, elevator wells, etc

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- Rock wool products and aluminum silicate acupuncture blankets are same

- Q: Rock wool insulation material fire rating is how much

- Fire protection and noise reduction of the elevator shaft of the building wall, the roof of the insulation, the firewall, the fire door, the large and medium diameter pipes, the small and medium sized storage tanks, the kilns, the thermal power plants, Boilers and other equipment insulation.

- Q: Rock wool board is inorganic composite insulation material

- Rock wool composite insulation material depends on what you compound the material

Send your message to us

Rock Wool Reinforced High Quality Industrial Furnace Used High Chrome Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords