Mannheim Furnace Potassium SulfateSOP Complete Sets Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

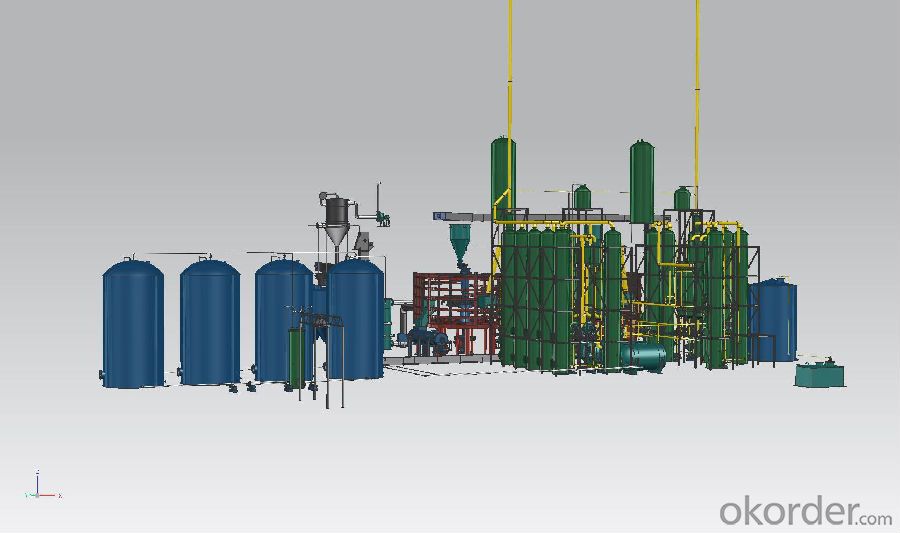

Potassium chloride reacts with concentrated sulfuric acid at a temperature of 500~530 to produce potassium sulfate and hydrogen chloride.Hydrogen chloride is absorbed into hydrochloric acid.Potassium sulfate complete set meets the above process requirements.The equipment includes the following systems:

1. Feeding system, sulfuric acid storage tank, acid high tank, lower acid pipe road, potassium chloride hopper, lower material pipe, KCL dryer, scraper, bucket lift.

2. The reaction system, mainly the host system.Center rounded corners, distribution of potassium chloride, sulfuric acid distribution, mixing arm, wind water cones and wick protection tile, trailing arm, trailing arm cases, axis, axis, base system, big gear and small gear, main motor, main reducer, large and small pulley.

3. Discharging system, potassium sulfate, potassium sulfate inclined exports, cooling material piling machine, sealing device, pulley, blowing machine, bucket, crusher, screw conveyor, potassium sulfate product hopper.

4.The acid system and the generated chlorinated hydrogen are exported from the hydrogen chloride into the buffer tank, and in the graphite cooling machine, desulphurization tower, and then the hydrochloric acid is generated through a suction tower and two suction tower.The remaining exhaust is further washed and then discharged into the air.The above description is the complete equipment of the potassium sulfate process, as well as the cooling water system and the electric control system.

1 | SOP Equipment manufacturer | The development, design and manufacture of mechanical parts and non mechanical parts of potassium sulphate have 30 years' history of producing the equipment. |

2 | SOP Production equipment | Discharging equipment reacting furnace, material equipment making acid equipment |

3 | Mannheim Machinery and equipment | Main motor,belt, scraper,bucket elevator,grinder (output and delivery value 4 tons /omn. hor.) |

4 | Mannheim Equipment manufacturer | The history of making Mannheim furnace is 30 years. |

5 | SOP host system | Including:Spiral feeding machine ,output pipe, Furnace central cylinder,distributor,Rake arm,Rake teeth,Sweeper brick container,Potassium sulfate exit ,Discharging cooler,Upper shaft,Air cooled and water cooled cone,Central axis,Base system,Big belt pulley,Small belt pulley,Pinion gear set,Big gear,Main motor,Main Reduction box |

6 | SOP Material Delivery system |

KCL Dryer ,KCL scraper,KCL bucket elevator, Big spiral feeding machine,sop belt,sop bucket elevator |

7 | SOP feeding system | Disc dryer ,scraper,bucket elevator,KCL charging bucket,KCL pipe,KCL distributor,Sulfuric acid storage tank,Sulfuric acid high level tank,H2SO4 pipe,H2SO4 distributor |

8 | SOP acid system. | Carbon cooling tower, desulfurizing tower, falling film absorption tower, two suction tower, tail gas washing tower, hydrogen chloride fan, hydrochloric acid intermediate tank, hydrochloric acid storage tank, and hydrochloric acid entrucking system

|

9 | SOP crusher | hammer crusher,4 tons /omn. hor. |

10 | SOP production line | Output system, reaction system, discharging system, acid making system, and finished product packaging system |

11 | SOP Production accessories | quick-wear part: KCL pipe,H2SO4 pipe,KCL distributor,H2SO4 distributor,Rake teeth, Rake teeth protective sleeve,Furnace core protective cap |

12 | SOP Equipment system Rake teeth | New -type rake teeth,the fourth generation and the fifth generation,they are: cardiac fixation and back fixation, which can be used for 3 years. |

13 | SOP Equipment system protective sleeve | The new material: Hua Ming 1, can be used for 3 years consecutively. |

14 | SOP Equipment system Rake arm | Durable, life for 10 years. |

15 | SOP Equipment system H2SO4 distributor | Pipe blanking, no spatter. |

16 | SOP Equipment system KCL distributor | The lengthening of the feeding trough solves the problem of material accumulation in the center. |

17 | SOP Equipment system Airtight conveyor |

It output on side for enhancing the seal, and the reducer adopts the droop structure to save space. |

18 | SOP Equipment system Discharging cooler | |

19 | SOP produces vulnerable parts | quick-wear part: KCL pipe,H2SO4 pipe,KCL distributor,H2SO4 distributor,Rake teeth, Rake teeth protective sleeve,Furnace core protective cap |

Send your message to us

Mannheim Furnace Potassium SulfateSOP Complete Sets Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords