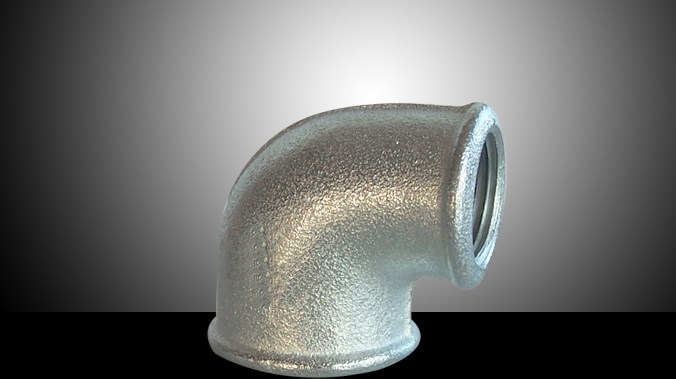

Malleable Iron Pipe Fitting Hot Dipped Galvanized on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: Are there any special coatings or linings used for ductile iron pipes?

- Ductile iron pipes utilize specialized coatings and linings to protect against corrosion and increase their lifespan. The interior and exterior surfaces of the pipes are treated with these coatings and linings. Several popular options for ductile iron pipes include cement mortar lining, polyethylene encasement, fusion bonded epoxy (FBE) coating, and polyurethane lining. Cement mortar lining is frequently employed to create a safeguarding layer on the inside of ductile iron pipes. This mixture of cement, sand, and water is applied to the pipe's interior surface. By doing so, it effectively prevents corrosion caused by water or other fluids flowing through the pipes. Polyethylene encasement is an additional protective coating used for ductile iron pipes. This method involves enveloping the pipes with a layer of polyethylene material. This barrier protects against environmental factors and inhibits direct contact between the pipe and the surrounding soil, minimizing the risk of corrosion. Fusion bonded epoxy (FBE) coating is a thermosetting epoxy powder coating that is administered to the exterior of ductile iron pipes. This coating provides exceptional corrosion resistance and mechanical protection. FBE coating is often utilized in aggressive environments where pipes are exposed to chemicals or high moisture conditions. Polyurethane lining is another type of lining employed for ductile iron pipes. It offers superior resistance to both corrosion and abrasion. This liquid polymer lining is sprayed onto the interior surface of the pipes, resulting in a smooth and durable protective layer that extends the life of the pipes. These coatings and linings are essential for maintaining the integrity and longevity of ductile iron pipes, ensuring optimal performance in a variety of applications such as water distribution, wastewater management, and industrial processes.

- Q: DN300 how long is it for water polo and iron pipes?

- Blue interface cast iron pipe, blue fixed inner cushion rubber, blue gasket seal; rigid joint like cast iron pipe mouth, compared with straight pipe inserted cement sealing process, has been basically eliminated

- Q: Comparison of ductile iron pipe and spiral steel pipe

- Ball milling cast iron pipe: corrosion resistance, high compressive strength, cheap, non pressure, socket connection.

- Q: DN1800 can the length of ductile iron pipes be several meters? What is the total weight?

- In quality, the spheroidization of cast iron pipes is controlled to be 1-3 (spheroidization rate 80%), so the mechanical properties of the cast iron pipes, ductile iron pipes and finished product libraries can be better improved, with the nature of iron and the properties of steel.

- Q: How are ductile iron pipes joined to fittings and valves?

- Ductile iron pipes are typically joined to fittings and valves using mechanical joint or push-on joint methods. The mechanical joint involves using a gland and a rubber gasket to create a tight seal when the pipe is bolted to the fitting or valve. On the other hand, push-on joint method uses a rubber gasket that is compressed when the pipe is pushed into the fitting or valve, providing a secure connection without the need for bolts or additional hardware.

- Q: Are there any specific standards or specifications for ductile iron pipes?

- Yes, there are specific standards and specifications for ductile iron pipes. The most commonly used standards for ductile iron pipes are set by the American Water Works Association (AWWA) and the International Organization for Standardization (ISO). The AWWA standard for ductile iron pipes is known as AWWA C151. This standard covers the design, manufacturing, testing, installation, and maintenance requirements for ductile iron pipes used in water and wastewater applications. It specifies the materials, dimensions, and mechanical properties of the pipes, as well as the required coatings and linings. Similarly, the ISO standard for ductile iron pipes is ISO 2531. This standard provides guidelines for the design, manufacturing, testing, and installation of ductile iron pipes for water and wastewater systems. It covers various aspects such as dimensions, mechanical properties, coatings, and linings. In addition to these two widely recognized standards, there may be other regional or national standards specific to certain countries or regions. These standards often align with the AWWA and ISO standards or may have additional requirements specific to local conditions or regulations. Compliance with these standards ensures that ductile iron pipes meet the necessary quality and performance requirements. It also facilitates the interoperability and compatibility of ductile iron pipes across different systems and countries, enabling reliable and efficient water distribution and wastewater management.

- Q: Are ductile iron pipes suitable for industrial applications?

- Ductile iron pipes are highly suitable for industrial applications, given their exceptional mechanical properties and durability. This material is strong and sturdy, making it ideal for high-pressure and heavy-duty tasks. These pipes possess a high tensile strength, enabling them to withstand extreme conditions like high temperatures and corrosive environments. Moreover, ductile iron pipes exhibit superior resistance to cracking and fracturing, resulting in a longer lifespan and reduced maintenance costs. They can also handle external loads effectively, making them perfect for underground installations and industrial settings where heavy loads or vibrations may be present. Furthermore, these pipes offer excellent flow characteristics due to their smooth interior surface, ensuring efficient fluid transportation in industrial systems. Their resistance to wear and abrasion guarantees a consistent flow rate over time. Additionally, ductile iron pipes are versatile and can be utilized in various industrial applications, including water supply, wastewater treatment, industrial processes, and mining operations. They are available in a wide range of sizes to meet different requirements and can be easily connected using various jointing methods. In conclusion, ductile iron pipes provide the reliability, strength, and longevity required for industrial applications, making them an ideal choice for industries where durability and performance are essential.

- Q: How many casting methods are there in ductile iron casting? A 60*6 discus can not have sand holes. Its surface is smooth. What process can be used to make it?

- The metal mould is ok! The surface quality of the casting is better than that of the sand mold. But later heat treatment is needed.

- Q: What is the expected external protection system for ductile iron pipes?

- The expected external protection system for ductile iron pipes typically includes a combination of coatings and cathodic protection. Coatings, such as fusion-bonded epoxy (FBE) or polyethylene, are applied to the external surface of the pipe to provide a barrier against corrosion and protect it from the surrounding environment. These coatings are highly resistant to moisture, chemicals, and abrasion, ensuring the longevity of the pipe. In addition to coatings, cathodic protection is often employed to further enhance the external protection of ductile iron pipes. Cathodic protection involves the use of sacrificial anodes or impressed current systems to create a protective electrical current that counteracts the corrosive effects on the pipe's surface. This technique helps prevent corrosion by ensuring that the ductile iron remains in a cathodic state, where it is less prone to degradation. The combination of coatings and cathodic protection provides a robust and comprehensive external protection system for ductile iron pipes. These measures effectively safeguard the pipes from corrosion, extending their service life and minimizing the need for costly repairs or replacements. Regular inspection and maintenance are also essential to ensure the ongoing effectiveness of the external protection system and to address any potential issues promptly.

- Q: Usage of ductile iron pipe expander

- Usage of ductile iron pipe expander:1, the expansion device should check its type, specification and piping configuration before installation, must comply with the design requirements.2, the expansion of the inner sleeve should be noted that the direction of the inner sleeve is consistent with the direction of the medium flow. The hinge rotation plane of the hinge type telescopic device should be consistent with the displacement rotation plane.3, the need for "cold tight" expansion device, pre deformation of the auxiliary components should be installed in the pipeline before they can be removed.4, it is strictly prohibited to use telescopic deformation method to adjust the installation of the pipe, so as not to affect the normal function of the telescopic device, reduce the service life and increase the piping, equipment and supporting components of the load.5 、 during installation, welding slag is not allowed to splash to the surface of wave shell, and the wave shell is not allowed to suffer other mechanical damage.6, pipe installation is completed, should be removed as soon as the wave expansion device used for installation and transportation of yellow auxiliary positioning components and fasteners, and according to the design requirements will be transferred to the specified position limiting device, the pipe system has the ability to compensate fully in the environmental conditions.

Send your message to us

Malleable Iron Pipe Fitting Hot Dipped Galvanized on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords