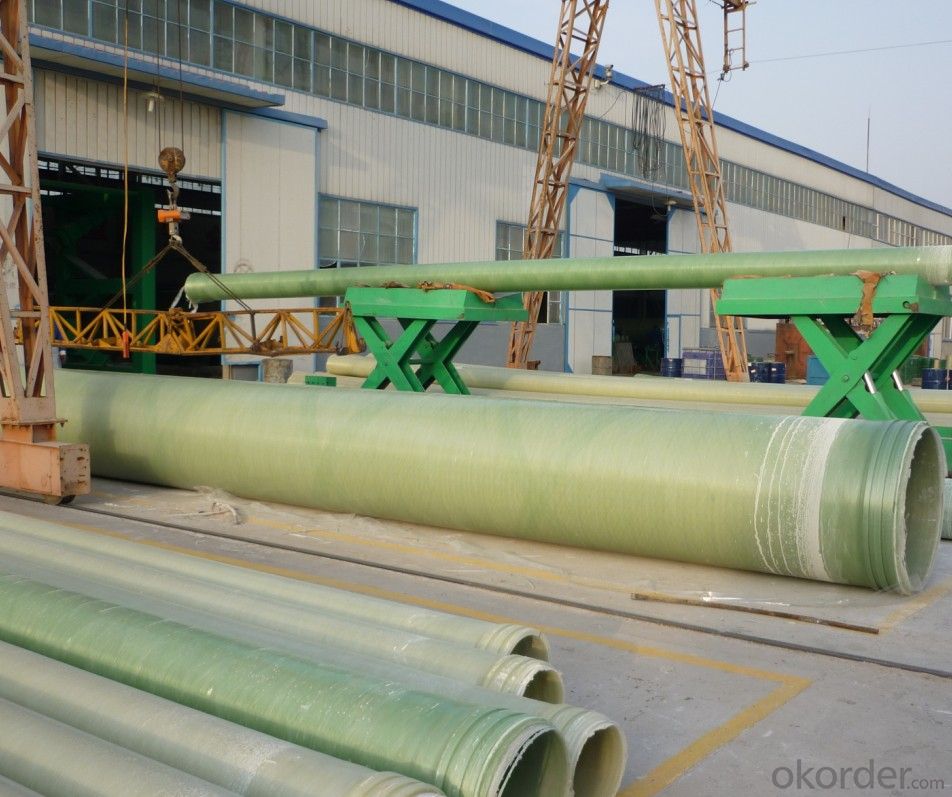

Composite Pipes - Maintenance Free FRP with Long Life Span Latest Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 430000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

COMPANT DESCRIPTION

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products, professional service and complete solution to our customers. Strong delivery capacity, advanced technology & management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

PRODUCT DESCRIPTION

1.Pipe Introduction

It is the ideal product for the transportations of the chemicals, drinking water, waste water, waste gas and sewer.

2.Characteristics

1. High anti-corrosion capability, long designed service time of 20 years;

2. Lightweight and facility to install and transport;

3. High specific intensity and reliable mechanical performance;

4. Low thermo-conductivity and small thermo-stress, which are allowed to be used in various conditions: exposed buried or suspended, in ocean or in deserts, freezing or humid;

5. Good electrical insulation

6. Not rust, rot or corrode, not permeate, and without consequent pollution.

3.Technical data

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

PACKAGING & DELIVERY

1.Packaging Details:

standard packing or your requirement

2.Delivery Detail:

Shipped in 25 days after payment

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce frp machines and frp products.

2.Q:If can customzied by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarntee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

- Q: Why FRP pipe corrosion?

- If it is ordinary water, generally does not count corrosion, there will be no obvious corrosion, long time began to soak rotten.

- Q: Is there any ventilation duct made of glass fibre reinforced plastic in Baotou?

- 1. Corrosion resistant FRP pipes resist acid, alkali, salt, sea water, untreated sewage, corrosive soil or groundwater, and the corrosion of numerous chemical fluids.2, good frost resistance FRP heat pipe temperature range between 40 to 80 DEG C, if the first with a special resin use temperature can reach higher.

- Q: Galvanized steel sheet and inorganic glass fibre reinforced plastic pipe are calculated according to this norm or norm

- The use of a fixed fare set without further consideration to duct losses has been included in the quota project

- Q: Pipe installation of glass fibre reinforced plastic pipe

- The slope of the pipeline shall be adjusted according to the requirements of the drawing. The adjustment method can be achieved by using the support to reach the slope requirement. The weld shall be located where it is convenient for inspection and observation.

- Q: Slurry circulation glass fiber reinforced plastic pipe

- The slurry circulation glass fiber reinforced plastic pipe has good heat resistance and frost resistance. It can be used in the range of 40 to 80 degrees for a long time. If the resin is specially formulated, it can work at temperatures above 110 degrees celsius.

- Q: What's the price of fiberglass reinforced sand pipes?

- Specifications: DN100--DN4000 are available.Thickness: 5mm--20mm, bothQ:28O5--9I343I/ I86+O38I+2OO7

- Q: What are the construction methods of glass fiber reinforced plastic paint anticorrosive pipes?

- Epoxy coal tar pitch is a kind of anti-corrosion form with high cost performance. The engineering test shows that the epoxy coal asphalt is used as cathodic protection.

- Q: What kind of diamond saw blade for cut glass steel pipe?

- Glass fiber reinforced plastic pipe is also called glass fiber winding sand pipe (RPM pipe). Mainly to the glass fiber and its products as reinforcing material, polymer composition of unsaturated polyester resin, epoxy resin as basic material, quartz sand and calcium carbonate and other inorganic non-metallic particles as filler materials as the main raw material. The standard effective length of the tube is 6m and 12M, and the production methods include fixed length winding process, centrifugal casting process and continuous winding process of three kinds. Classification can be carried out according to the product process method, pressure grade PN and stiffness grade SN.

- Q: What is the elastic modulus of glass fiber reinforced plastic?

- If so, the modulus of elasticity is 72000MPa, and the glass is isotropic, so the modulus of elasticity in the three directions is the value.

- Q: Excuse me, what standard does the glass fiber that check mechanical and electrical use accord with GB?

- The pipe wall structure reasonable and advanced, can give full play to the role of material, to meet the premise of use strength, improve the rigidity, ensure the stability and reliability of the product. Because of its excellent chemical resistance, light weight, high strength, no scaling and strong seismic resistance, the glass steel sand inclusion has the advantages of long service life, low overall cost, quick installation, safety and reliability compared with ordinary steel tubes.

Send your message to us

Composite Pipes - Maintenance Free FRP with Long Life Span Latest Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 430000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords