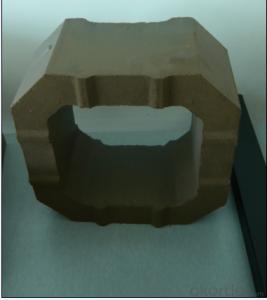

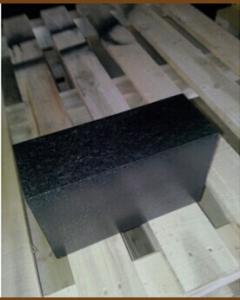

Magnesite Carbon Refractory Brick for Steel Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fused Magnesite (Ordinary Grade)

Magnesia Carbon Refractory Brick for Steel Mill (Ordinary Grade) is manufactured through fusing high quality raw magnesite in electric arc furnace with the characteristics of big crystal, dense structure and strong corrosion resistance. As an excellent basic refractory raw material, its MgO content is between 87 – 98%.

Fused Magnesite (Big Crystal)

Magnesia Carbon Refractory Brick (Big Crystal) is manufactured through fusing high quality calcined magnesite at high temperature in electric arc furnace with the characteristics of complete crystal, dense texture, good high temperature performance and strong corrosion resistance.

Magnesia Carbon Refractory Brick (Big Crystal) whose MgO content is between 97 – 99% is widely used in refractory industry. Meanwhile, it is also an excellent high-temperature endurable insulating material.

Brand Specifcation | YFM-98 | YFM-97.8 | YFM-97 | YFM-96 |

| MgO% | 97.8-98 | 97.5-97.8 | 97 | 96 |

| SiO2 ≤ % | 0.55 | 0.6 | 0.8 | 1.0 |

| CaO ≤ % | 1.1 | 1.2 | 1.6 | 2.0 |

| Fe2O ≤% | 0.5 | 0.6 | 0.8 | 1.0 |

| AL2O3 % | 0.2 | 0.2 | 0.2 | 0.2 |

| Bulk Density ≥% | 3.5 | 3.5 | 3.45 | 3.4 |

| Size | 0-150mm | 0-150mm | 0-150mm | 0-150mm |

Features of Magnesia Carbon Refractory Brick

High refractoriness

Good spalling resistance and wear resistance.

Good corrosion resistance.

Good thermal shock resistance.

High mechanical strength.

High-temperature creep rate is low.

- Q: Brick price?

- There are various series of unshaped refractory gunning, magnesia ramming material, mending material, coating material, dry lining material, composite refining agent, covering agent, tundish and tundish slag wall, ladle drainage sand and electric furnace taphole filler etc..

- Q: The index of magnesia brick

- Room temperature compressive strength≥(MPa)(15-25-)24.5-24.5-24.5-24.5-40-40-40

- Q: High purity magnesia brick masonry mortar for what?

- You try a mixture of aluminum phosphate. It itself is the main component of aluminum, which can not cause pollution. We use high temperature electric stove to bond with this.But this 800 degree won't be sintered. It won't sinter until more than 1000 degrees.

- Q: Manufacture of various refractory magnesia brick mainly comes from Magnesium Oxide, what kind of ore?

- Manufacture of various refractory magnesia brick Magnesium Oxide, mainly from magnesite.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- High alumina brick clay brick up to 1700 degrees above 1500 degrees -1750 degrees of magnesia brick and magnesia chrome brick 1500-1650 degrees, I is the production of clay brick, brick my temperature at 1500-1700 degrees. Specific depends on what kiln, brick is only part of it

- Q: With different capacitance magnesia brick brick

- It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.

- Q: Magnesia brick

- Magnesia brick have high refractoriness, alkali slag good performance, high load softening temperature, but poor thermal shock resistance. The sintering magnesia brick brick magnesite as raw material, crushing, proportioning, mixing, forming, in 1550 ~ 1600 degrees firing, high purity products firing temperature is over 1750 DEG C. Don't add chemical bond magnesia brick is appropriate in magnesia, through mixing, molding and drying

- Q: How to identify the fused magnesia brick and sintered magnesia brick

- Magnesia brick (magnesite brick) basic refractories Magnesium Oxide content of more than 90%, with the main crystalline phase of periclase

- Q: How do you differentiate between the two clearly? Where is the key? Thank you

- Magnesia brick have high refractoriness, alkali slag good performance, high load softening temperature, but poor thermal shock resistance. The sintering magnesia brick brick magnesite as raw material, crushing, proportioning, mixing, forming, in 1550 ~ 1600 degrees firing, high purity products firing temperature is over 1750 DEG C. Don't add chemical bond magnesia brick is appropriate in magnesia, through mixing, molding and drying.

- Q: Magnesite chrome brick, magnesia chrome brick indicators? What is the price?.

- According to the actual situation, design the brick you need, and the price of brick is determined by the index.

Send your message to us

Magnesite Carbon Refractory Brick for Steel Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords