Magnesia Brick MZ91

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Tons m.t.

- Supply Capability:

- 30000 Tons per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Magnesia Brick MZ91

Magnesia bricks MZ91 are made from sintered magnesium. The magnesia bricks are belong to alkali series refractories and widely used in alkaline atmosphere. The magnesia bricks are produced by crushing, mixing, pressing, drying and burning. A variety of type could be done according to customer’s drawing.

Characteristics of Magnesia Brick MZ91

Our magnesia bricks MZ87 exhibit the following characteristics:

High refractoriness temperature

Strong resistance to slag

Good high temperature properties

Technical Data of Magnesia Brick MZ91

|

Sintered Magnesia Brick---MZ91 | ||

|

Physical Properties: |

|

|

|

Cold Crushing Strength |

Mpa |

60 |

|

Apparent Porosity |

% |

18 |

|

Refractories Under Load(0.2Mpa) |

℃ |

1560 |

|

Reheating Linear Change (1650 ℃x2h) |

% |

0~-0.4 |

|

Chemical Analysis: |

|

|

|

MgO |

% |

91.0 |

|

CaO |

% |

3.0 |

|

Note: Technical Data are typical average results from test pieces.The technical data is offered solely for your consideration.And CNBM reserve the right to modify the technical data without any prior notice.Users of CNBM products should make their own tests to determine the suitability of each products for their particular purposes. | ||

Typical Application of Magnesia Brick MZ91

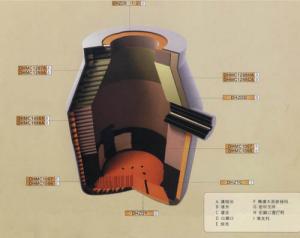

Typical applications of magnesia bricks include ferroalloy furnace, metal mixer, Non-metallurgy industry furnace, high temperature kiln, calcined lime furnace, regenerator in glass furnace.

We has success in magnesia bricks due to their cost-effectiveness, excellent thermal shock resistant and high temperature properties. CNBM also has experience in magnesia brick application and would like to assist you in product selection, system design, and installation techniques.

- Q: Brick price?

- Refractory brick series sintered magnesia brick, magnesia chrome brick, magnesia brick, magnesia spinel brick, magnesia calcium brick, unburned magnesia chrome brick, magnesia brick, magnesia calcium brick, magnesia brick, and al2o3-mgo-c bricks.

- Q: The index of magnesia brick

- Room temperature compressive strength≥(MPa)(15-25-)24.5-24.5-24.5-24.5-40-40-40

- Q: Manufacture of various refractory magnesia brick mainly comes from Magnesium Oxide, what kind of ore?

- Manufacture of various refractory magnesia brick Magnesium Oxide, mainly from magnesite.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- The super high alumina brick in high alumina refractory brick has the highest refractoriness, and the corresponding production cost is higher.

- Q: With different capacitance magnesia brick brick

- Fused magnesia brick brick has compact structure, high mechanical strength,It is mainly used for thermal storage of large glass furnaceHigh temperature area of the room.

- Q: Magnesia brick

- Magnesia brick (magnesite brick) basic refractories Magnesium Oxide content of more than 90%, with the main crystalline phase of periclase. General can be divided into sintered magnesia brick (also called burnt magnesia brick) and chemically bonded magnesia brick (also known as the two major categories of not burned magnesia brick). Purity and high firing temperature of magnesia, due to the direct contact of periclase grains, known as direct bonded magnesite brick; made of fused magnesia bricks called electrically fused magnesite brick.

- Q: How to identify the fused magnesia brick and sintered magnesia brick

- Magnesia brick (magnesite brick) basic refractories Magnesium Oxide content of more than 90%, with the main crystalline phase of periclase

- Q: Process for producing magnesia chrome brick

- The fine powder compacts after calcination produced by magnesia - chrome ore grinding method, brick with magnesia coarse particles, are effective measures to eliminate the effect of loose. Compared with the common magnesia chrome brick, the magnesia chrome brick made by this method has lower porosity, higher compressive strength, higher softening temperature and higher flexural strength. Compacts with chrome magnesite powder, magnesia chrome brick by synthetic magnesia chrome sand made of high-temperature calcination, slag resistance and high temperature strength are better than other magnesite chrome brick.

- Q: How do you differentiate between the two clearly? Where is the key? Thank you

- Burnt magnesia brick is made of high quality sintered magnesia as main raw materials, paper pulp as binder. After mixing and high pressure molding, it is fired in a high temperature tunnel kiln over 1550 degrees celsius. It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.Fused magnesia brick brick has compact structure, high mechanical strength, low impurity content, mainly used for the storage of large glass kiln

- Q: Magnesite chrome brick, magnesia chrome brick indicators? What is the price?.

- If you want to know the indicators of chrome brick, magnesia chrome brick must know you are in what furnace above, there is in what position

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | Taiwan; Germany; Italy; Turkey; France; England; Japan; Thailand; Vietnam; Idonesia; Egypt; Ukraine |

| Company Certifications | ISO 9001:2008;GB/T 19001-2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 10%-20% |

| No.of Employees in Trade Department | 3 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Fifty thousand tons per year |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Magnesia Brick MZ91

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Tons m.t.

- Supply Capability:

- 30000 Tons per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords