Magnesite Zirconia Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

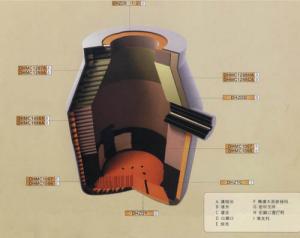

CMAX magnesite-zirconia brick is a kind of magnesia brick which added ZrO2, and is a kind of alkali resistance refractory brick.

Quick Details

| Place of Origin: | Shape: | Material: | |||

| SiO2 Content (%): | Al2O3 Content (%): | MgO Content (%): | |||

| CaO Content (%): | Refractoriness (Degree): | CrO Content (%): | |||

| SiC Content (%): | Model Number: | Brand Name: |

Packaging & Delivery

| Packaging Detail: | According to customer requirements |

| Delivery Detail: | 40-60 days after the order |

Specifications

Magnesite-Zirconia Brick is used for regenerator of glass tank furnace,the service life can reach more than 8 year.

Magnesite-Zirconia Brick | HMZr-A | HMZr-B |

MgO% ≥ | 76 | 73 |

ZrO2 %≥ | 12.5 | 12.5 |

Apparent Porosity%≤ | 13 | 15 |

Bulk Density (g/cm3)≥ | 3.18 | 3.10 |

Cold Crushing Strength (MPa)≥ | 60 | 50 |

Refractoriness Under Load°C≥ | 1700 | 1650 |

Thermal Shock Resistance(950-wind cold)≥ | 20 | 20 |

- Q: Application of electric high temperature regulating valve?

- Magnesia brick has good resistance to alkaline slag and slag, refractory clay brick and brick high ratio. Mainly used in open hearth furnace, oxygen converter, electric furnace, non-ferrous metal smelting equipment and glass industry as well as some high temperature equipment. Magnesia chrome brick more resistant to alkaline slag, and thermal shock stability are much higher than the more widely used, magnesia, magnesia chrome bricks in iron and steel smelting and non-ferrous metal smelting industry has almost replaced the brick, chrome oxide containing (Cr2O3) can be spread, the magnesium chromium brick can easily sticking kiln the skin, so in the past 30 years, has been used with refractory preferred cement kiln, magnesia chrome brick in Cr2O3 water after the reaction of trivalent chromium into six chromium can cause the pollution on the water, facing gradually out of the cement industry market trends. Magnesia and magnesia alumina brick using alumina as raw materials, a magnesia brick compared to thermal shock resistance and high temperature creep performance, use parts and magnesia brick is almost the same. Dolomite brick and magnesia calcium brick performance is almost the same, dolomite brick using dolomite as raw material, calcium magnesium brick with synthetic calcium magnesium sand as raw materials, calcium oxide content in 15-30%, the other is the main component of Magnesium Oxide, with the function of purifying molten steel, usually only used for special steel smelting, the production process of magnesia calcium brick complex water and water steam, easy decomposition, not easy to save transportation, do preventive work must be used in the process of. Magnesia spinel brick is a kind of new products, mainly for the zone and transition zone of cement rotary kiln, will be the main products of the cement industry to replace magnesia chrome brick.

Send your message to us

Magnesite Zirconia Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords