Corundum Magnesia Alumina Spinel Brick with CE Certificate for Fired Cement Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Place of Origin: | Shandong, China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 50%~65% | Al2O3 Content (%): | 42% | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) |

| Model Number: | SK34 | Brand Name: | CCEFIRE | Product name: | CNBM |

| Standard: | ASTM &JIS | Density: | 2.15-2.2g/cm3 | Fe content: | ≤2% |

| Standard Size: | 230*114*65/75mm | Porosity: | ≤26% | Refractoriness under Load (C): | ≥1300% |

| Refractoriness: | ≥1730C |

Packaging & Delivery

| Packaging Details: | Pallet or carton |

| Delivery Detail: | 7-15 working days after payment |

Product Description

MAKE FURNACE ENERGY EFFICIENCY SIMPLER

Fired Cement Kiln Magnesia Alumina Spinel Brick

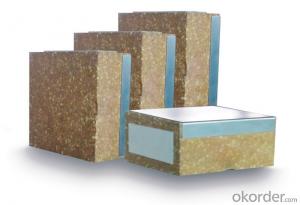

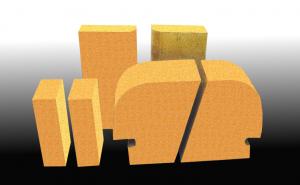

refers to fire brick containing Al2O3 more than 48%, which is made of high grade bauxite through high temperature calcinations. It is is a kind of neutral refractory material so that it enjoys excellent resistance to acid and alkali corrosion. It has characteristic of high refractoriness under load, which decide high alumina brick is a n ideal material for various kinds of industrial furnace. It is widely used in building lining of hot-blast stove, blast furnace, coke oven, rotary kilns of cement and so on.

Name | CCEFIRE Fired Cement Kiln Magnesia Alumina Spinel Brick |

Size and Specifications | 230x114x65mm 230x114x75mm |

Type | High Alumina Brick |

Characteristics | 1 Excellent thermal stability 2 High refractoriness under load 3 Chemical stability and anti-corrision 4 Small high temperature creep rate 5 Excellent thermal shock resistance |

Typical Use | 1 Building materials for blast furnace 2 Building materials for hot-blast stove 3 Building materials for coke oven 4 Building materials for steel making furnace 5 For ladle 6 For construction material in steel industry |

- Q: What are the advantages of refractories?

- Aluminosilicate refractory refractory material refers to SiO2-Al2O3 as the main ingredient, according to how much the Al2O3 content can be divided into semi silica (Al2O3 15~30%), clay (Al2O3 30~48%), high alumina (Al2O3 > 48%) three.

- Q: What is the price of concrete self insulation bricks?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q: What is the blast furnace ceramic cup called by the refractory factory?

- In fact, a kind of ceramic cup of blast furnace refractories, application in blast furnace bottom and hearth contact steel lining using a layer of non carbon refractory materials, such as Theron with corundum brick, corundum mullite and synthetic mullite bricks etc..

- Q: What's the jade stove for?

- Is it a furnace made of corundum or a furnace for smelting corundum?Corundum brick stove is commonly used as a refractory material sintering furnace, can be fired refractoriness in refractories, below 1700 degrees such as brick, corundum brick, brick, alumina hollow ball and so on

- Q: Expansion ratio of lightweight corundum refractory bricks

- Now with the production of lightweight foam corundum brick, basically still meters with molding casting, moulding after together with die in the drying room drying in 60~70 C 4 days of release, then the appropriate drying, finally after 1300 and 1550 C firing, the total burning time: 50~60h. Light corundum brick after firing is usually not the size and shape of accurate, so that products after the kiln to mechanical or manual cutting, can be made into a density of 0.8 - 1.3g/cm3, 4MPa compressive strength and porosity, the thermal conductivity of 70%~80% 0.17W/ (M - K), light-weight corundum brick use temperature of 1500~1700 DEG C.

- Q: How to improve the induction furnace campaign, from the promotion of refractory life start

- According to the use of atmosphere, choose the appropriate spraying materials, such as infrared radiation paint

- Q: What is the hardness of corundum refractory bricks?

- Al2O3 containing more than 90% greater than the refractory brick called corundum refractory brick, also known as pure alumina refractory products. Corundum has a high hardness (9 Mohs hardness) and a high melting point. These are closely related to the firmness of the Al - 0 bond in the structure. Therefore, a-Al2O3 is the main phase of making high temperature refractory bricks and high temperature electrical insulating materials.

- Q: What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- The fused zirconia corundum brick is made up of 30% ~ 41% zirconia two in the alumina burden. The main mineral compositions are corundum, zircon and glass phase. The main varieties are fused (or cast) zirconium corundum brick (also known as AZS casting brick) and sintered zirconia corundum brick. Generally speaking, zircon corundum brick means sintered zirconia corundum brick. It is made from alpha -Al2O3, partially stabilized zirconia and zircon corundum clinker, which is prepared by proportioning and molding at 1700~1750 DEG C and then sintered at two. The sintered zirconium corundum brick has a strong resistance to molten glass, and its thermal shock resistance is stronger than that of fused zirconia corundum brick. It is mainly used as lining of glass furnace and induction furnace, as well as steel rolling furnace, slide rail, etc..

- Q: What are the refractory materials?

- Basic refractories in Magnesium Oxide and calcium oxide as the main ingredient, commonly used is brick. Magnesium Oxide 80% to more than 85% containing magnesia brick, has good resistance to alkaline slag and slag, refractory clay brick and brick high ratio. Mainly used in open hearth furnace, oxygen converter, electric furnace, non-ferrous metal smelting equipment and high temperature equipment.

- Q: What kind of rock is corundum produced?

- Aluminum oxide (Al2O3) mineral. Due to Mohs hardness of up to 9, mainly used as high-grade abrasives. The crystal belongs to the three party system, a dolioform six square column, some are needle or plate. Aggregates are massive or columnar. Usually white, gray, yellow and other colors. If a small amount of Cr3+ is red, a ruby is called;

Send your message to us

Corundum Magnesia Alumina Spinel Brick with CE Certificate for Fired Cement Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords