High Alumina Brick - Low Thermal Conductivity Diatomite Firebrick for Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

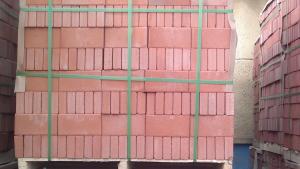

| Packaging Details: | Standard export wooden pallet with cardboard, 480pieces/pallet for standard size |

low thermal conductitity diatomite firebrick for kiln

Product Description

B series insulation bricks are made from high purity raw material according to different brick type to meet different requirement.

They are ideal thermal insulation material usually used in industrial furnaces and heating pipe.

Our insulation bricks are in accordance with JIS Industrial Standard of JAPAN, have excellent properties as light weight, low ferrous, low shrinkage, atmosphere erosion resistant and so on.

Features and advantage:

1. Light weight

2. Low density

3. High strength,good thermal shock resistance

4. Low heat storage, low thermal conductivity

5. Saving energy

6. Precise size

7. Good thermal insulation effect

8. Good quality and low price

Application:

It is widely used as a primary hot face refractory lining or as back-up insulation behind other refractory in furnace(such as carbon furnace, cracking furnace, heating furnace for oil refining, roller kiln, tunnel kiln.), flues, refining vessels, heaters, regenerators and similar high temperature industrial equipment.

- Q: What's the difference between high alumina refractory bricks and high alumina refractory bricks?

- High alumina refractory brick in all thermal shock properties except performance are better than clay refractory brick, masonry in furnace and thermal equipment, such as clay bricks can be competent the work environment is not high aluminum brick masonry.

- Q: How to reduce porosity of high alumina brick

- High alumina brick used as refractory products in refractory material, has a great application in masonry kilns, insiders pointed out that the quality of high alumina brick general porosity and it has a great relationship! So, how to reduce the porosity of high alumina brick rate is very important!

- Q: What are the alloy wear resistance materials?

- According to the composition of Beijing Naimo metal materials company will wear resistant metal materials is divided into the following five categories: one: high manganese steel series: high manganese steel (ZGMn13),

- Q: What are the specifications for bricks?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels. Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: Are there any differences between insulating bricks and refractory bricks?

- The refractoriness of insulating bricks is generally below 1400 tons, while the refractoriness of refractory bricks is above 1400 degrees. 3. density insulation bricks are generally lightweight insulation materials, the density is generally in 0.8-1.0g/cm3, and the density of refractory bricks are basically above 2.0g/cm3.

- Q: How are the grades of high alumina bricks differentiated?

- If the content of Al2O3 is higher than 90%, it is called corundum brick. Because of the different resources, the standards of different countries are not exactly the sameFor example, European countries limit the content of Al2O3 for high alumina refractory materials at 42%.

- Q: Is glass wool inorganic thermal insulation material?

- The use of glass wool, glass wool is usually used as raw materials of various types of insulation materials, such as glass wool board, glass wool, glass wool, glass wool pipe, can be used in the following areas:1) roof insulation, cold protection, sound-absorbing materials; 2) building exterior wall insulation and cold protection; 3) entertainment places, theaters, television stations, radio stations, laboratories, sound absorption treatment.

- Q: Which thermal shock stability of clay brick and high alumina brick is good?

- Generally, the thermal shock resistance of high alumina brick products is worse than that of clay brick products

- Q: What is the difference between fireclay bricks and high alumina refractory bricks?

- A neutral refractory with an alumina content of more than 48%. Made from alumina or other raw materials of high alumina content; formed and calcined. High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining.

Send your message to us

High Alumina Brick - Low Thermal Conductivity Diatomite Firebrick for Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords