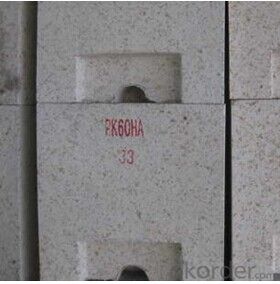

Low Creep Andalusite Fused Cast Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: Made from Mullite and andalusite as starting materials, the bricks are processed into shapes by moulding under high pressure and sintering are high temperature, with feature of lower impurity contents, low porosity ,low bulk density,strong strength at high temperature,steady bulk at high temperature,high thermal shock resistance and small creep rate,which are mainly used for HBS.

Brand Index | LHZ-150 | LHZ-145 | LHZ-140 | LHZ-135 |

Al2O3, % ≥ |

|

|

|

|

Fe2O3, %, ≥ | 1.0 | 1.0 | 1.3 | 1.3 |

AP, % ≤ | 1810 | 1810 | 1790 | 1790 |

BD, g/cm³ ≥ |

|

|

|

|

Refractoriness, °C ≥ |

|

|

|

|

CCS, MPa ≥ | 65(55) | 65(55) | 70(60) | 70(60) |

0.2MPa RUL, °C ≥ | 1650 | 1650 | 1630 | 1600 |

PLC(1500°C x 5h), % | 0~+0.5 | 0~+0.5 | 0~+0.5 | 0~+0.5 |

Thermal shock resistance, | 30 | 25 | 25 | 20 |

Creep rate, % ≤ | 0.8 (1500°Cx50h) | 0.8 (1450°Cx50h) | 0.8 (1400°Cx50h) | 0.8 (1400°Cx50h) |

Specifications

1,Low Creep andalusite brick

2,Resisting high temperature.

3,Great bulk density.

4,Low iron content.

- Q: How are qualitative and qualitative refractories understood?

- Unshaped refractory products, referred to as bulk loading, are made at the place of use for the required shapes and for heat treatment, such as castable, ramming, projection, spray, refractory clay, etc..

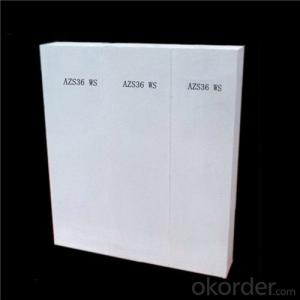

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- The fused zirconia corundum brick is mainly made of fused zirconia and corundum. ZrO2-Al2O3-SiO2 three element system fused brick, containing Al2O3:40% to 50%, ZrO2:30% to 50%, SiO2:10% to 17%.From the point of view of data analysis, there is no radioactive substance in it, and it will not cause harm to the human body.

- Q: What are the categories of bricks?

- Fired shale brick as a new building energy-saving wall materials, which can be used for masonry walls, but also has good thermal properties, in line with the construction of the building module, reduce the loss in the process of construction, loss and high work efficiency; the hole rate reached more than 35%, can reduce the weight of the wall, save the foundation engineering cost. Compared with common sintered porous brick, the Jian Ling brick has the characteristics of heat preservation, heat insulation, light weight, high strength and high construction efficiency. The product is made of shale as raw material. It is produced by high vacuum extrusion molding machine and one yard firing process

- Q: Just what is in the furnace material?

- It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Referred to as refractory brick. Refractory wood made from refractory clay or other refractory material

- Q: What are kiln bricks?

- Furnace (kiln; furnace; oven) is made of refractory material used for firing products; it is a necessary facility in the formation of ceramic art. Millions of years of human porcelain history, has accumulated rich experience and made kiln style. From the primitive society to open pile burn, burn up like digging to build Steamed Buns flame round kiln, half pour flame kiln, kiln, Banpo horseshoe shaped kiln to duck's egg, indoor gas kiln, kiln kiln electric current, in the continuous improvement in the development of science and technology.

- Q: What are the specifications for bricks?

- Thecompressive node as a new type of building energy-saving wall materials, which can be used for masonry walls, but also has good thermal properties, in line with the construction of the building module, reduce the loss in the process of construction, improve work efficiency; the hole rate reached more than 35%, can reduce the weight of the wall, save the foundation engineering cost. Compared with common sintered porous brick, it has the characteristics of heat preservation, heat insulation, light weight, high strength and high construction efficiency. The product is made of shale as raw material. It is produced by high vacuum extrusion molding machine and one yard firing process

- Q: Is the wall around the fire area using a firewall? What's the difference between a fireproof brick and a regular brick?

- Fire bricks burn well!!In fact, the firewall does not necessarily have to use the so-called "fire brick", but to see the brick fire limit!240, the fire limit seems to be 4 hours, 370 I do not remember clearly, fire codes have, you see, do not think so naive!

- Q: What's the use of refractory bricks?

- Refractory bricks are mostly used in the lining of furnaces of high temperature industries. Such as iron and steel industry, blast furnace, hot blast furnace, converter, colored reverberatory furnace, rotary kiln, etc.

- Q: Can the fire clay be reused?

- Refractory soil cannot be reused.Clay refractory soil 1, characteristics and uses: Clay refractory brick is a weak acid refractory material, its thermal stability is good, suitable for hot air furnace, all kinds of boiler lining, and flue, smoke room, etc.. 2, product specifications form: standard shape, general, special-shaped and special-shaped brick. Physical and chemical properties of fireclay bricks.

Send your message to us

Low Creep Andalusite Fused Cast Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords