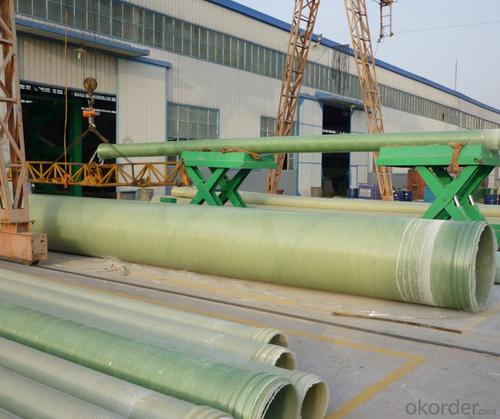

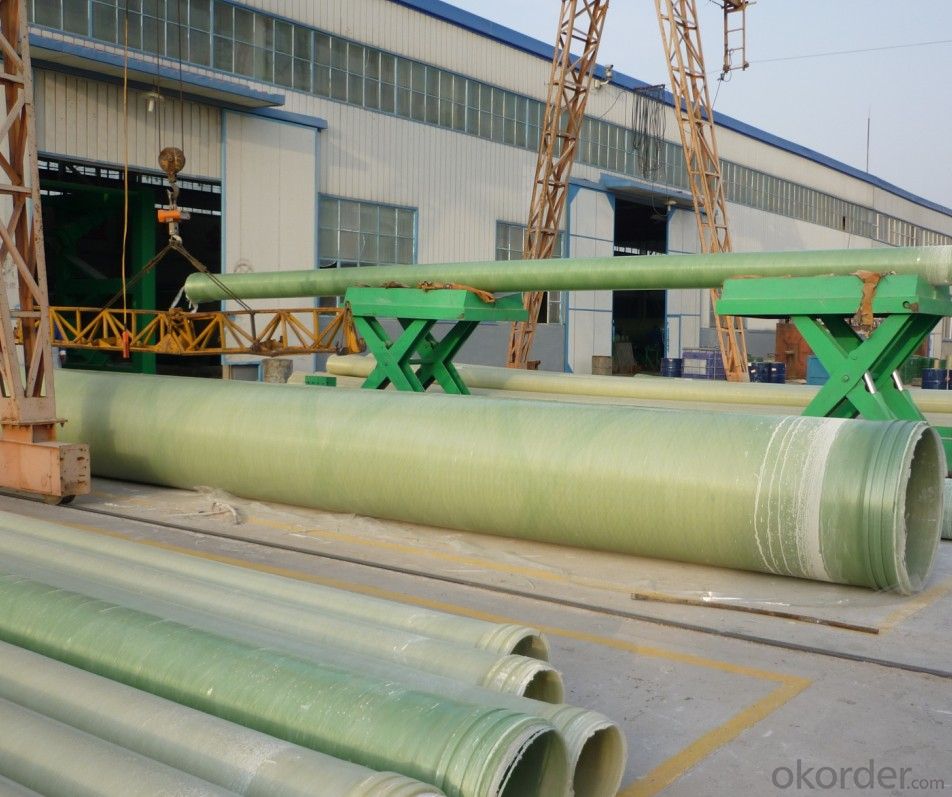

Composite Pipes - Lightweight FRP Pipe with High Endurance and Rapid Assembly

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

1.Pipe Introduction

It is the ideal product for the transportations of the chemicals, drinking water, wastewater, waste gas and sewer.

2.Characteristics

1. High anti-corrosion capability, long designed service time of 20 years;

2. Good hydraulic property, smooth inner surface with absolute roughness of 0.01mm, which is far less than that of carbon steel pipe or cast iron pipe;

3. Lightweight and facility to install and transport;

4. High specific intensity and reliable mechanical performance;

5. Low thermo-conductivity and small thermo-stress, which are allowed to be used in various conditions: exposed buried or suspended, in ocean or in deserts, freezing or humid;

3.Technical Data

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

PACKAGING & DELIVERY

1.Packaging Details

standard packing or your requirement

2.Delivery Detail

Shipped in 26 days after payment

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

- Q: Glass fiber reinforced plastic pipe to withstand 1.0MPa pressure, pipe wall to do how much thickness?

- Glass tube wall thickness is generally determined by the manufacturer design, with stereotypes products and sequences, you can choose according to the pressure level.

- Q: Is it useful to make gas pipelines with glass steel pipes? Or the idea that the technology is mature?

- There are ideas, corrosion problems resolved, you can consider the use of casing, you have to consider the length of the pipeline, glass tube links. And that's the pressure on the glass.

- Q: Glass fiber reinforced plastic GRE pipe broken hole how to repair and repair?

- Don't let the powder go. It is autumn, the temperature is low, so to put more than summer curing agent, as to the exact proportion, I just guess should be: curing agent, accelerator, resin; 1:1.5:8 with glass fiber wrapped around the pipe, coated on the glass fiber cloth to make glass steel with good quickly, let the glass steel the glass fiber cloth fully soaked, waiting for the full glass steel after curing, and then repeated several layers. It will be strong.

- Q: Glass tube has different diameters with different prices. Who can elaborate?

- The standard for FRP pipe execution is GB21238-2007

- Q: What are the materials used in smoke exhaust pipes?

- According to the current national standards: ventilation pipe exhaust pipe material selection of steel pipe (steel), galvanized plate (Bai Tie) smoke pipe, the exhaust pipe exhaust pipe, exhaust pipe, stainless steel pipe, plastic glass smoke exhaust pipe, composite sandwich insulation board, industrial exhaust pipe exhaust exhaust pipe.

- Q: Is there any ventilation duct made of glass fibre reinforced plastic in Baotou?

- 1. Corrosion resistant FRP pipes resist acid, alkali, salt, sea water, untreated sewage, corrosive soil or groundwater, and the corrosion of numerous chemical fluids.2, good frost resistance FRP heat pipe temperature range between 40 to 80 DEG C, if the first with a special resin use temperature can reach higher.

- Q: How to repair and repair the broken hole of GRE glass fiber reinforced plastic pipe?

- The service will be restored in 24 hours, and I hope this will help you! Can private letter to contact is not clear!

- Q: Glass fiber reinforced plastic pipeline to do anti-corrosion?

- Glass steel pipe does not need to do anti-corrosion treatment, the material itself is the biggest advantage of corrosion resistance

- Q: What kind of diamond saw blade for cut glass steel pipe?

- It is better to use ceramic stem slice, thin, toothless and wear less.

- Q: What are FRP pipes used for making? What raw materials?

- The glass tube with its unique strong corrosion resistance, smooth surface materials, low energy consumption and long service life (50 years), convenient transportation and installation, maintenance and many other advantages of low cost and low cost in electric power, petroleum, chemical industry, papermaking, city water supply and drainage, sewage treatment plant, seawater desalination, gas transportation other industries have been widely applied.

Send your message to us

Composite Pipes - Lightweight FRP Pipe with High Endurance and Rapid Assembly

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords