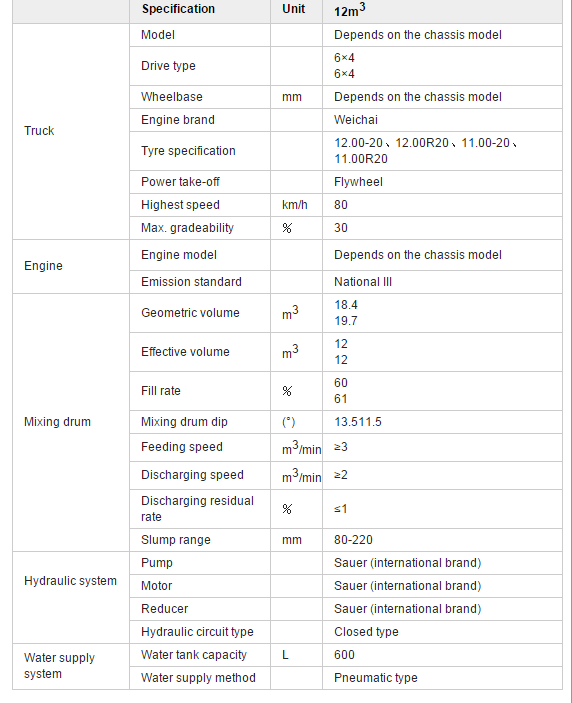

12m³ Concrete truck mixer / ISO & CE certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 8 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

12m³ Concrete truck mixer / ISO & CE certificate

Specification

Hydraulic system

•The split hydraulic system features low cost and easy maintenance;

•The best hydraulic system assembly in the world.

•The company has good relationship with leading hydraulic system manufacturers. The hydraulic system is the most reliable, featuring compact structure and easy maintenance.

•The hydraulic pump suspension frame adopts U type bolt fixing, featuring good interchangeability and easy maintenance; It adopts Sauer hydraulic oil pump, motor and reducer.

Water supply system

•Large water tank capacity; One-time water using cycle is long;

•Pneumatic type water supply; Washing system, high water supply pressure, clean the feeding hopper and, discharging slot, tank and other equipment;

•One switch on the bottom of the cleaning system, which can discharge the water completely in winter.

•The water pump and shower nozzle are arranged reasonably, which are easy to operate.

Operation system

•It adopts the control method of mechanical linkage, and optimize the traditional operation structure, which is easier and more reliable for the operator.

•The cab adds the internal operation handle, which is easy for operation without getting off.

•Control the mixing and discharging speed by the throttle, and load (acceleration) and unload (acceleration) the material.

•Optimize the operation reliability, and eliminate the safety loophole.

Feeding and discharging system

•Add the quick coupler for watering, and the optimized hopper is easy to feed and discharge the concrete;

•The feeding height of less than 3850mm is suitable for the mixer, and the upper of feeding hopper is less than 650mm;

•The discharging height of 1350mm-1550mm is suitable for the feeding inlet of the pump;

Upper electrical system

•The electrical system is in single line, with negative pole on iron. The line voltage is 24V.

•The electrical system consists of illuminator, hydraulic oil temperature control switch, relay, and fan motor. When the oil temperature is over 60°C, the temperature control switch will connect and the cooling fan will rotate; when the oil temperature is below 55°C, the temperature control switch will disconnect and the cooling fan will stop.

•The work lamp switch controls the work lamp.

- Q: How many layers of steel wire tyres are used in concrete mixers

- Concrete agitator truck tyres are usually used in 18 levels of steel wire tyres, which is used in 20 levels

- Q: What is the normal speed in the transportation of the concrete mixer

- 1 to 3 RPM for transportation Normal 0 -- 6 is all right

- Q: How many years does the concrete agitator truck go away?

- Usually use life for 8 to 10 years, but there is no special provision for discarded concrete transporter, is generally in accordance with the provisions of other vehicles in the motor vehicle standards: use fixed number of year for 10 years, can carry out the delay to 4 years. Because of concrete transport vehicle is a special vehicle, this is generally will have certain preferential treatment for scrap.

- Q: What is the car for concrete

- These trucks are equipped with cylindrical agitating cylinders to carry mixed concrete. During the course of transportation, the mixer will be kept rotating to ensure that the concrete is not frozen. After the concrete is transported, it is usually used to flush the inside of the cylinder to prevent the hardened concrete from taking up space, making the cylinder volume less and less

- Q: The concrete mixer transporter is running continuously for no more than one hour

- In the tolerable weight, as long as the complete system is not subject to problems (such as heat, oil pressure, stirring, etc.), it can be continuously constructed. The farthest shipping distance I've ever seen is 45 kilometers, no problem at all.

- Q: s the collapse of four concrete mixer trucks

- The degree of slump refers to the ease of concrete, which is specifically to ensure the normal operation of the construction, including the water retention, liquidity and cohesion of the concrete. Workability is refers to the concrete mixture is easy to operation, mixing, transportation, pouring and tamping), and uniform quality, compacted concrete performance. It is a comprehensive technical property, including water retention, liquidity and cohesion. The main factors of influence and ease are the water usage, the ratio of water ash ratio, the ratio of sand, including the variety of cement, aggregate condition, time and temperature, admixture and so on.

- Q: Is a tanker and a mixer a thing

- Usually a concrete mixer is called a tanker But the tanker also has a concrete factory that transports the bulk cement, and USES the long can to drag the engine

- Q: What can be done to remove the concrete from the concrete mixer truck

- This is the worst case scenario, you don't have to think about it, just change the tank, don't think about how you can save the money. It's a big lesson.

- Q: Why is the concrete mixer turning on the road?

- Because concrete is according to certain proportion with the mixture of the water cement ratio is one of the important factors, the size of water cement ratio directly determine the quality of concrete. In the process of concrete transportation, which is to keep the concrete maintain form without condensation, otherwise it will make concrete loss have building performance.

- Q: What is the difference between a concrete mixer and a tanker?

- A special truck used to transport construction concrete; Because of its appearance, it is also commonly referred to as the tian. These trucks are equipped with cylindrical agitating cylinders to carry mixed concrete. By the automobile chassis, mixing barrel, transmission system, water supply equipment, take full power and power, before and after the mixing drum support, deceleration machine, hydraulic transmission system, material in and out of the system, operating mechanism and other parts. Due to the technical bottleneck, the domestic mixer can be made from 3m to 8m cubic meters, and the four large parts of the volume are imported. Composition: type 2 chassis, drive system, hydraulic system, frame, mixing tank, feeding system, water supply system, operating system, ladder and so on. The top of the mixing tank is mounted on the rack, and the rear end is supported by two supporting wheels mounted behind the chassis.

Send your message to us

12m³ Concrete truck mixer / ISO & CE certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 8 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords