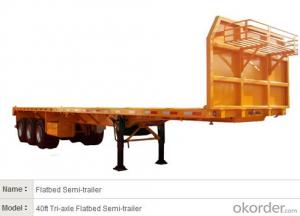

Dropdeck Flatbed Semi Trailer with Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Name: Dropdeck Flatbed Semi Trailer with Good Quality

1. Specification

ITEM | Semi Trailer | MODEL | CMAX211468 |

DIMENTION(mm) | 8450×2500×2700 | TOTAL WEIGHT(Kg) | 16000 |

LOAD WEIGHT(Kg) | 12500 | ||

STEELSPRING PLATE | 8/10 | MACHINE WEIGHT(Kg) | 3500 |

AXLES | 1 | ||

AXLES DISTANCE | 6000 | ||

TIRE NUMBER | 4 | ||

FRONT/BACK OVERHANG(mm) | -/1700 | ||

TIRE STANDARD | 11.00-20,12.00-20,11.00R20,12.00R20 | ||

2. Application

Cement Container and delivery.

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce Dropdeck Flatbed Semi Trailer with Good Quality according to customers request?

A4: Yes, we can produce Dropdeck Flatbed Semi Trailer with Good Quality according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

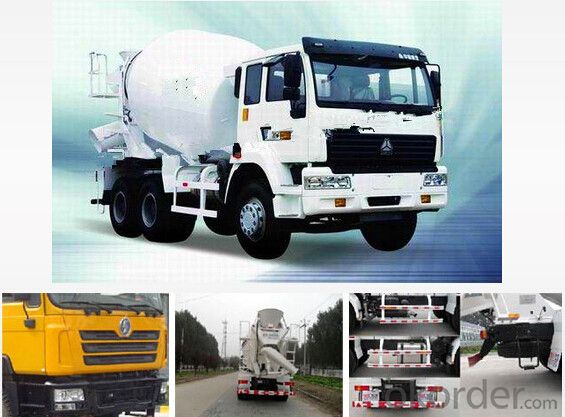

- Q: How many layers of steel wire tyres are used in concrete mixers

- 1200R20 R: represents a wire or a meridian 20: a hierarchy.

- Q: Is it possible to mix the concrete in a mixing truck for eight hours?

- The concrete was stirred in the blender truck for eight hours and if it was added, there was no problem. In the case of not add water to let out a bit to see, if haven't lost the plastic concrete, slump of qualified, can continue to use, otherwise, had to be abandoned, or as aggregate, points repeatedly to stir.

- Q: How many years does the concrete agitator truck go away?

- Usually use life for 8 to 10 years, but there is no special provision for discarded concrete transporter, is generally in accordance with the provisions of other vehicles in the motor vehicle standards: use fixed number of year for 10 years, can carry out the delay to 4 years. Because of concrete transport vehicle is a special vehicle, this is generally will have certain preferential treatment for scrap.

- Q: The concrete mixer transporter is running continuously for no more than one hour

- The concrete mixer transporter is running for no more than 8 hours. Concrete mixing is divided into two kinds: artificial mixing and mechanical stirring Manual stirring search When stirring, try to be quick, stirring time from adding water, should meet the following rules in general: The volume of the mixture is 4 ~ 5min (minute) under 30L. The volume of the mixture is 30L - 50L at 5-9min The volume of the mixture is 51L - 75L at 9 ~ 12min After mixing, it is required to do the slump measurement or the specimen forming according to the test requirement. The total operation must be completed in 30min from the beginning of the addition of water.Mechanical agitation First, it is the first batch, which is to make the ripper first, so as not to affect the mixing ratio of the mix. Start the mixer, blender, in turn, to join the gravel, sand and cement, stir evenly, add the water slowly again, all charging time not more than 2 min, water after all to join, to continue mixing 2 min.

- Q: s the collapse of four concrete mixer trucks

- Do you mean the concrete can be transported by the concrete mixer? If that's the case, then I say clearly, no, it's a problem that the slump is put in and out of the car. The average slump is 100 to 120mm, and it is better not to transport the concrete transporter, and the best way to do it is to search for it.

- Q: What are the three main parts of the concrete mixer car

- The three main parts of a concrete mixer are oil pump, motor and speed reducer. The function of oil pump: provide constant power for hydraulic oil. The function of the motor: converts the power of the hydraulic oil into mechanical power and is transmitted to the decelerator. Decelerator: reduce the speed of the hydraulic motor

- Q: How many cubic meters of concrete mixer transport vehicle

- Dongfeng 140 concrete mixer truck, dongfeng 145 concrete mixer truck, dongfeng 153 concrete mixer truck, dongfeng hercules concrete mixer truck, dongfeng tianlong build concrete mixer truck concrete mixers, liberation, steyr, concrete mixer truck concrete mixer truck, hongyan, Europe man special concrete mixer truck concrete mixers and other projects.

- Q: Does it affect the ease of mixing too long?

- Are now using concrete products, easy to control the quality, intensity can be measured, can also add additive, etc., only their own building the in-situ mixing, transportation for a long time will affect the workability, so the project will adopt water mud and water reducing agent, etc.

- Q: What is the driving license for a concrete mixer truck?

- It requires a B2 photo, and the corresponding driving model is a large van. Heavy-duty, medium sized special operations vehicle, quasi-driving and code name:

- Q: What can be done to remove the concrete from the concrete mixer truck

- The shovel shovel Conditional to buy a pneumatic spatula knife, only to find in the area of material removal lon-izing dozen, can a small amount of hydrochloric acid or outside the shovel shovel shovel, car or flushing timely, keep clean can adhere to, once the dirty is not in the mood in the lane

Send your message to us

Dropdeck Flatbed Semi Trailer with Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords