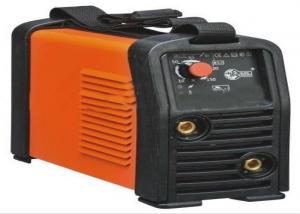

LGK8-40 63 100 160 Air Plasma Cutting Machine

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LGK8-40/63/100/160 Air Plasma Cutting Machine

Quick Details

· Condition: New

· Place of Origin: Shanghai, China (Mainland)

· Brand Name: OEM

· Model Number: LGK8-40

· Input Voltage: 3-380V+/-10%

· Rated Current: 40

· Dimensions: 70KGS

· Usage: Suitable for various rough pieces cutting, esp. for non-ferrous metal

· Certification: ISO9001:2008; CCC

· Color: Gray

Features

1 A new cutting technology for metal materials

2 Melt and cut the materials with high temperature and high speed air plasma

3 Only compressed air and 3 Phases power supply, no need expensive gas to cut Stainless steel, Carbon steel, Alloy steel, Aluminum, Copper, Nickel and Titanium, etc.

4 Cutting speed fast, cutting narrow, deformation less, materials saving and cost effective

Technical Parameter

Model | LGK8-40 | LGK8-63 | LGK8-100 | LGK8-160 |

Rated Input Voltage(V) | 3~380 | 3~380 | 3~380 | 3~380 |

Rated Input Power(kV/A) | 11.2 | 19.8 | 30 | 49.4 |

Rated Welding Voltage (V) | 96 | 105 | 120 | 144 |

Rated Cutting Current(A) | 40 | 63 | 100 | 160 |

Cutting thickness(mm) | ≤12 | ≤18 | ≤30 | ≤50 |

Air Pressure (MPa) | 0.3-0.5 | 0.3-0.5 | 0.4-0.6 | 0.25-0.4 |

Rated Duty Cycle (%) | 60 | 60 | 60 | 60 |

Weight | 70 | 85 | 120 | 290 |

- Q: There are several kinds of arc welding machine, argon arc welding machine and several kinds. What are their occupational hazards?

- Manual arc weldingArgon tungsten arc weldingCarbon dioxide gas shielded arc weldingsubmerged arc weldingmetal inert-gas welding

- Q: Excuse me: how about the power of 315 DC arc welding machine?

- Usually around 12~13 / taiwan.. The 3 is estimated to be 40KAV

- Q: How do we need welding with argon arc welding machine, and what tools do we need? Please explain in detail, satisfaction added 10 points

- DC argon arc welding machine is not welding aluminum, with DC argon arc welder, welding of aluminum can, to communicate with, if you need to pass beautiful with DC argon arc welder with pulse welding sheet, do not fill the thick aluminum wire, you need to fill in the aluminum wire.

- Q: You ask about the quality of argon arc welding machine which brand is good, the requirements of aluminum welding, welding and cutting thickness below 20mm, 12mm can also be used, or DC inverter AC / DC, what model is appropriate, about how much the price, thank you!

- To solder aluminum, the general welding machine or model is difficult to achieve good welding effect, technical requirements are higher. Still, this time choose Aotai welding quality and relatively high visibility. As for those small cards do not suggest that you buy, generally difficult to effect, but also delay the construction period. Our factory has encountered such a situation, then buy the okuta welding machine, the welding quality and reliability are also good.

- Q: Argon arc welding machine on the ignition, note: switch is not bad, what is the matter?

- Take a look at the fuse on the board

- Q: DC pulse TIG welding machine 315A, welding machine in normal operation, this machine can also be electric arc welding, arc welding, argon arc welding arc tungsten does not press the switch contact welding when the arc, but a contact will be brought to the short circuit, tungsten welding on nabuxialai, I put the machine box. The arc contact distance adjustable to 1mm, press the switch will arc slightly, but the feeling current is very small, not big, do not know what the reason is, the machine internal check in online photos, some say that the high frequency transformer is bad, but I see there is a high voltage transformer don't know what is.

- Is it all right to call the manufacturer?!

- Q: What is the straight line mark on an argon arc welding machine?

- This is the WSM welding machine, DC welding machine. A picture is square wave / DC choice. The next one is the 2 section welding, welding and 4 segment type specific choice. Do not say, you try to know. Hint, long welding is convenient

- Q: Reallink type 200 argon arc welding machine, power line with the square of the number of the power line to 10 meters?Hope to give professional answers!220 volt electricity input current manual 28-43 welding machine superscript 22-28 is the best professional electrician to answer O (a _ U) O thank you

- If the use of argon arc welding 2.5 square is enough, manual welding is also used, then use 4 square lines is enough, and the maximum input current is about 25A.

- Q: What products can be welded by automatic argon arc welding machine?

- There are so many things to weld that you are not very professional about it

- Q: How much electricity does an argon arc welding machine use in a day?

- 315 welding machine 12KW, 400 welding machine 15kw., this is full load when the power, output current is different, the total power consumption is different, and welding always has a pause, so the power consumption is uncertain!

Send your message to us

LGK8-40 63 100 160 Air Plasma Cutting Machine

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords