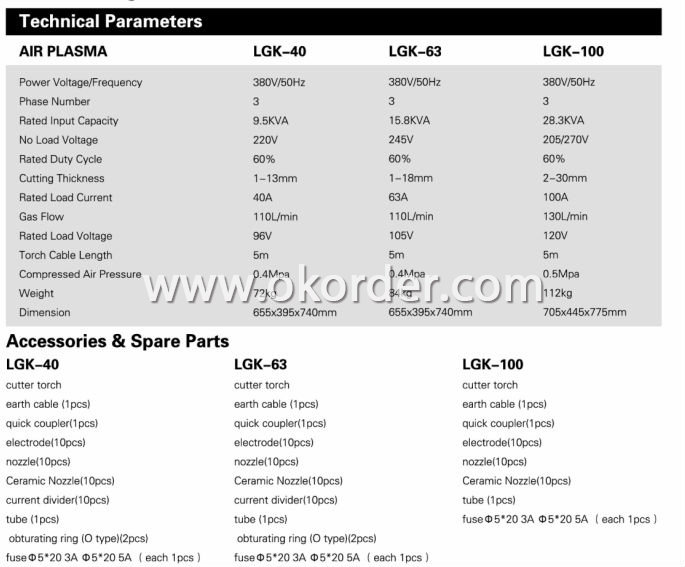

Air Plasma ARC Cutting Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1000 Sets per Week set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

AIR PLASMA ARC CUTTING MACHINE

1)can cut all kins of conductive material

3)manufacturer

4)ISO9001

- Q: What brand of MAG/MIG welding machine good stability high load rate (the main processing non-ferrous metals such as copper and aluminum) and the teacher requested to introduce.

- Germany's Fries 3000 type AC and DC welding machine, and then the aviation industry is very popular, but the price is high. And the Miller welding machine made in America, especially good for butt welding. You can refer to the reference.

- Q: What are the principles of Tandem twin wire welding and monofilament composite pulsed MIG welding?

- LZ, this name is interesting. Double wire welding is two welding machines, both guns at the same time welding, can be the same arc pit, can also be a front, a rear, two arc pit, or both sides simultaneously. Yes, the welding wire is different and the welding parameters are different. Double Pulse GMAW, two pulse superposition, with wave superposition theory as a pulse for welding, one droplet per pulse, a pulse, is responsible for the scale pattern.

- Q: MIG automatic welding is always broken arc is how ah?

- There are several reasons for arcing:First, the power load capacity is poor.1, power line is too long, too small;2, the power supply voltage is too low, two, welding machine itself problems1, secondary current adjustment is too small, and the diameter of the welding rod does not match.2, each node serious corrosion, bad contact.Three. Welding rod quality problem.1, welding rod itself quality is slightly lower,2, welding rod damp, medicine skin deterioration or failure.

- Q: The difference between TIG welding and MIG welding

- TIG is a non melting electrode TIG welding, is a manual electric arc welding with argon gas protection, while MIG belongs to inert gas welding consumable electrode, and the TIG is different to manual wire for automatic wire feeding.

- Q: Which is better, TIG welding method and MIG welding method?

- TIG welding method and MIG welding method must be MIG better, mainly reflected in1) shaping well2) high efficiency3) TIG can be welded to some limited materials, and sizes, such as large plates, thick platesFrom a practical point of view, TIG welding method is more practical than MIG welding, mainly reflected in1) TIG generally based on the same brand, TIG is cheaper2) the cost of using is also lower3) general TIG is relatively easy to carry4) more popular, more suitable for small batch and spare parts welding.

- Q: The difference between MAG welding machine and MIG welding machine

- Active gas shielded arc welding (MIG) can be applied to most of the major metals, including carbon steel and alloy steel.Inert gas shielded welding (MAG) is suitable for stainless steel, aluminum, magnesium, copper, titanium, zirconium and nickel alloys. The arc welding can be carried out by using the welding method.

We produce high quality and outstanding performance AC drives. We have developed full range AC drives to meet the most needs of customers. Sanyu drives have been widely used in many industries from low end market to high end market. In China, there are hundreds of authorized distributors and technicians who are ready to serve our customers at any time.

1. Manufacturer Overview

| Location | Shanghai,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia |

| Company Certifications | CE ,certificate of conformity;CE LVD;ISO certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | SHANGHAI,GUANGZHOU |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese, Spanish, Portuguese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Air Plasma ARC Cutting Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1000 Sets per Week set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords