Plastic Tubes Lasted PPR Pipe Fitting for Industrial System

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Application

Distribution for cool and hot water;

Duct for drinkable water system;

Pipes for kinds of high-temperature and low-temperature heating system;

Pipes for heating and cooling settings in solar energy system;

Connecting pipe for air conditioners.

Product Description

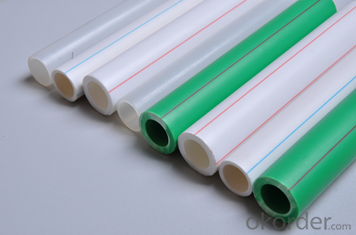

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Show

FAQ

Q: If the products have some quality problem ,how will you deal with it?

A: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind. Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q.How can I get a sample?

A: FREE SAMPLE can be sent to you .Freight will be collect

Q. Is free design assistance available for clients?

A: If you have problems in designing or beautifying the customized product, we will offer you the best design assistance.Pictures

Q:, Which factors can be customized?

A: Material, Color, Size, Packing ,Brand, delivery

Q; Advantages of your products?

A:Company products, good quality, high reputation guarantee.

Our Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

- Q: How do you connect plastic tubes together?

- Plastic tubes can be connected together using various methods such as push-fit connectors, compression fittings, barbed connectors, or using adhesive or solvent-based joining techniques like gluing or welding. The appropriate method depends on the specific application, tube material, and required strength and durability.

- Q: why doesnt the plastic top of superglue stick to the tube?

- The glue does not stick because the plastic on the inside is to smooth for it to stick. Also it does not dry on the inside because they need air to dry in

- Q: Are plastic tubes safe for food packaging?

- Yes, plastic tubes can be safe for food packaging. However, it depends on the type of plastic used and whether it meets food-grade standards. Food-safe plastics like high-density polyethylene (HDPE) or polypropylene (PP) are commonly used for packaging foods in plastic tubes. These materials are non-toxic, resistant to chemicals, and have low risk of leaching harmful substances into the food. It's important to ensure that the plastic tubes are manufactured according to food safety regulations and properly labeled as food-grade packaging.

- Q: How do plastic tubes compare to metal tubes?

- Plastic tubes generally offer advantages such as lower cost, lightweight nature, and resistance to corrosion, while metal tubes tend to provide better durability, higher strength, and increased temperature and pressure resistance. The choice between plastic and metal tubes depends on the specific application requirements and priorities.

- Q: What are the temperature limitations of plastic tubes?

- The temperature limitations of plastic tubes vary depending on the type of plastic used. Generally, most common plastics can withstand temperatures between -40°C to 80°C (-40°F to 176°F). However, some specialty plastics can handle higher temperatures up to 200°C (392°F) or more. It is always recommended to check the specific specifications provided by the manufacturer for precise temperature limitations.

- Q: I was changing my engine oil via the dipstick tube and a special suction device that pumps the old oil out of the sump to be replaced with fresh oil. Unfortunately, i had to patch up a hole in the tube on the suction device with parcel tape/sellotape wrapped around and a small piece of tape (around 2x2 square) fell into the engine dipstick tube and appears to have slid down into the oil sump.Will the oil filter make any difference in keeping melted plastic out of the engine? Am i best calling up the manufacturer, not the dealer as i don't want them to know about my error. The engine still runs and i have driven 20 miles so far with no problems. 2009 year Citroen C1Thanks

- if the peice of tape gets 'sucked onto the oil pump pick up screen it will stop lubrication of the whole engine and engine failure. I would get it out asap and do the next oil change in the proper manner.

- Q: A meat baster consists of a squeeze bulb attached to a plastic tube. When the bulb is squeezed and released, with the open end of the tube under the surface of the basting sauce, the sauce rises in the tube to a distance h, as the drawing shows. It can then be squirted over the meat.Using 1.013e+05 Pa for the atmospheric pressure and 1100 kg/m3 for the density of the sauce, find the absolute pressure in the bulb when the distance h is each of the following.(c) h = 0.140 m Pa=?(d) h = 1.10 10-1 m Pa=?

- The pressure difference dP from the top to the bottom of a liquid column of height h = gh*density. Then at the top of the column and in the bulb, P = 1.013E5 Pa - dP = 1.013E5 - 9.8*0.14*1100 = 99790.8 Pa (for question C). You can do the same for question D.

- Q: I am looking for a lightweight, easy-to-tear, food-safe plastic to be used with a heat sealer to package homemade baked goods. More specifically, dipped pretzel rods. Ideally, a roll of narrow width would be best. That way, I can insert the pretzel and seal both short ends, and so on. There seems to be an abundance of the more rubbery polyethelene tubing available, but it is very difficult to break apart. Think Twinkie plastic. Suggestions would be greatly appreciated! Thanx.

- They also might be able to steer you to someone

- Q: What is the minimum bending radius of plastic tubes?

- The minimum bending radius of plastic tubes depends on the specific type of plastic being used. However, as a general rule, most plastic tubes have a minimum bending radius of around 1-2 times the tube's outer diameter.

- Q: How long do plastic tubes last?

- The lifespan of plastic tubes can vary depending on their quality, usage, and maintenance. On average, plastic tubes can last anywhere from a few months to several years. However, factors such as exposure to harsh chemicals, extreme temperatures, or physical stress can significantly impact their durability and longevity.

Send your message to us

Plastic Tubes Lasted PPR Pipe Fitting for Industrial System

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords