JXP-180 Automatic liner Bottle Rinser Made In China Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Product Details:

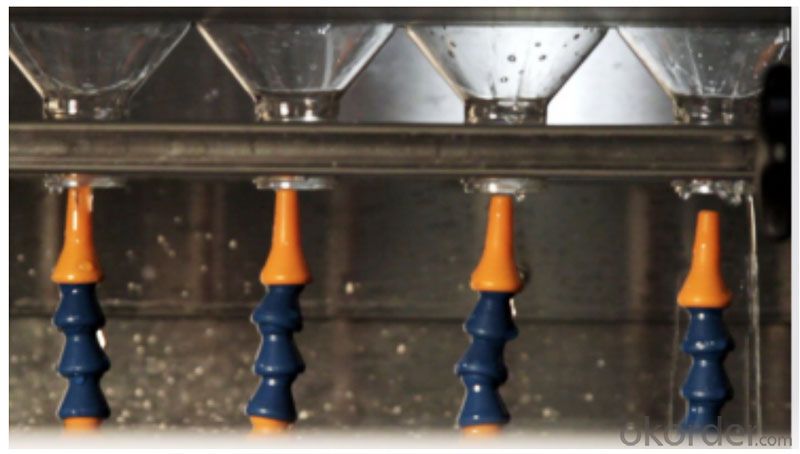

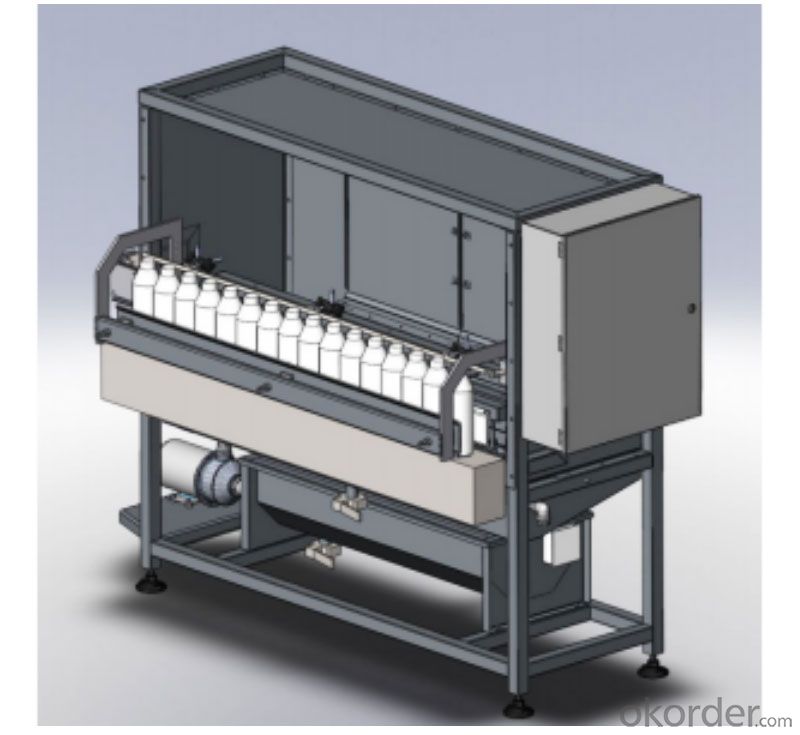

JPACKS Automatic Linear Water Rinser is used to remove dust particles and other dry contaminants from clean containers. Typically used in the bottled water industry, this Water Rinser can also be utilized in a variety of other industries that require rinsed containers prior to filling. The containers are automatically indexed into the Rinser. The grippers capture the containers and then invert them 180 degrees over the adjustable Rinse Heads. High pressure jets individually rinse the containers internally with product water or customer-supplied rinse media. Once rinsed, containers are briefly drained and are reverted back onto the conveyor. The Automatic Linear Water Rinser comes standard with PLC Controls and color touch screen HMI, Pneumatic Indexing Gates, No bottle/No rinse and Bottle Backup Sensors, plus many more. Additional options are available for even more versatility.

2、Standard Features:

1 Fingertip knob adjustable jets for different bottle width

2 PLC Controls with color touch screen HMI

3 Pneumatic Indexing Gates (Entry and Exit)

4 Overall electronic production counter

5 No bottle/No rinse Sensor

6 Bottle Backup Sensor (downstream) delays operation 1.7 until jam is cleared

7 On/off and speed controls for Conveyor

8 10 memory locations for rinse and indexing recipes

9 Front panel Start and Emergency Stop

10 Mounted on 4 heavy duty casters, plus threaded leveling legs

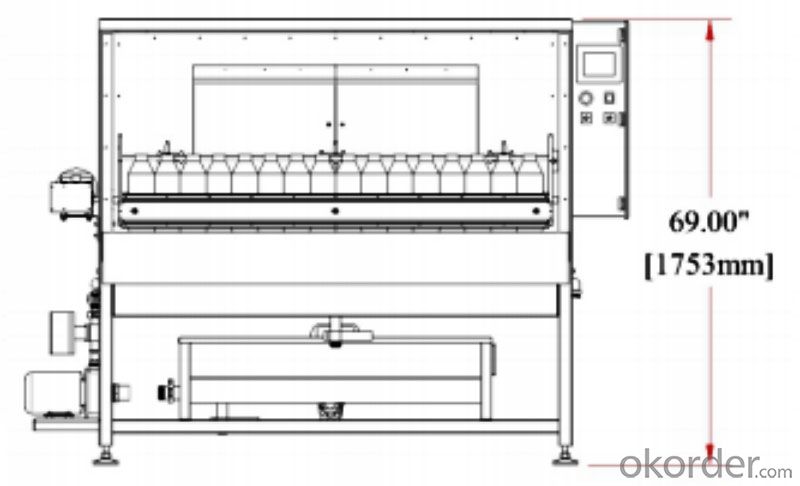

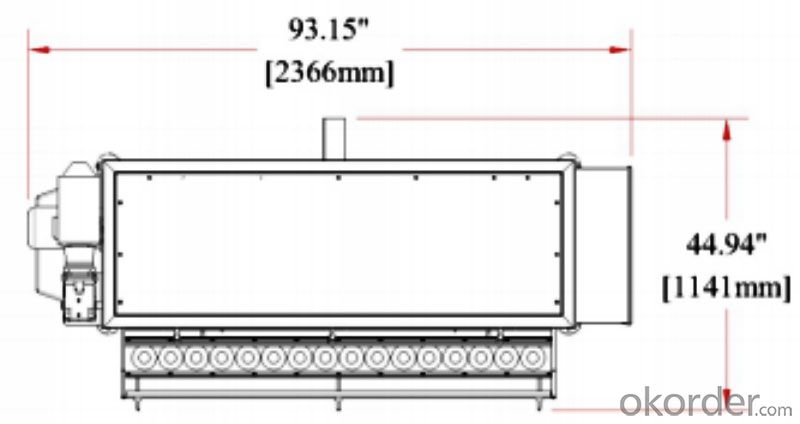

3、Specifications:

1 Standard Construction: Heavy duty 304SS 48” frame with some anodized aluminum

2 Rinse Head: Virtually all container sizes

3 Rinse Time: Variable, typically 2 to 3 seconds per container

4 Standard Line Height: Typically 36”

5 Power Requirement: 220VAC, single phase, 30 amp, 50-60Hz

6 Air Requirement: 2CFM @ 90PSI clean, dry, compressed air

7 Dimensions & Weight: Subject to model configuration

4、Options:

1 1 to 16 Rinse Heads

2 Larger frame for more Rinse Heads

3 Air Knife

4 Custom applications

5 Special electrical requirements

6 Sanitary, hazardous, flammable and corrosive environment construction

5、Images:

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q: Cookies with tinplate packaging has what advantage

- Barrier: tinplate cans have excellent barrier properties than any other materials are excellent, gas barrier properties, moisture resistance, shading and aroma were good, and the sealing is reliable, reliable protection products.

- Q: What are the categories of packing materials?

- Ceramic packaging materials: ceramic bottles, ceramic cylinders, ceramic altar, ceramic pot; 5, glass packaging materials: glass bottles, glass cans, glass boxes;

- Q: What's the packing bag for rice and noodles?

- When the temperature is more than 50 degrees centigrade, the poisonous components in the plastic bag will seep out and contaminate the food. When the temperature reaches 80 degrees centigrade, the heat will be melted and the poisonous substance will be released.

- Q: What are the sales packing materials?

- Packaging in the main plastic bags and corrugated box packaging, corrugated boxes are mainly FOL, TUCK, TOP, BOX and so on; (three) the outer packing is generally used in export cartons, 5 corrugated boxes, corrugated mainly B/C watts. The outer box price calculation formula is: (long + width +8) /100 x (width + high +6) /100 X per square unit price. The length, width and height of the units are CM. For example, the size of an outer box is 60 X, 30 X, 40 CM, and the price is (60+30+8) /100, X (30+40+6), /100, X 6 (market price) = 4.47 yuan.

- Q: What's the difference between the materials used in kraft paper packaging?

- Kraft paper, packaging, color boxes, books, flowers, etc., is very goodAccording to the kraft paper kraft paper packaging is often used for Baixin generally useful good grades three points almost useful useful still better.Almost crisp, the surface is not so smooth, generally more smooth, stiffness, tension, a little better, the better is the double-sided smooth, similar to cement bags that kind of paper packaging is sure that the wood has a problem ~!

- Q: What are the commonly used packing materials?

- Metal packaging materials: tin foil hoop steel strapping buckle Blister aluminum PTP aluminum foil steel buckle ceramic glass material wood

- Q: What kind of fruit package do you have?

- Fruit packaging, pet plastic fruit packing box, PET material, environmental protection non-toxic, not only moisture-proof, the product is also transparent, beautiful, smooth, light weight. And there are air holes, to ensure the flow of air, but also affixed labels, indicating fruit information, so that customers at a glance.

- Q: What's the difference between a package and a package?

- Packaging refers to the packaging of products for the storage of various types of containers, such as barrels, boxes, bottles, jars, bags and other materials used for storage and custody of products.Packaging used in the manufacturing process as a component of a product and included in the cost of production at actual cost".

- Q: What's bread packing? Polyethylene film, waterproof cellophane, etc.

- BOPP (biaxially oriented polypropylene), //VMCPP (aluminized cast polypropylene) or PET (biaxially stretched polyester film), //VMCPP (aluminium plated cast polypropylene), exactly the same as what was said upstairs, two, just like that.Carton: carton with various specifications, 3.5.7.9.11, K type, W type, A type, B type, C type, E type, F type, B3B pit paper, Taiwan yellow K paper. The angle of paper available in cartons with additional protection, fixed on the tray outside angle, the cushioning edge protection reinforcement effect.

- Q: What's the function of pearl cotton packing material?

- Polyethylene foam cotton is a non crosslinked closed cell structure, also known as EPE pearl cotton, is a new type of environmentally friendly packaging materials. It consists of low density polyethylene, which is physically foamed and produces numerous independent bubbles. To overcome the ordinary styrofoam brittle deformation, recovery of the shortcomings of the poor.

Send your message to us

JXP-180 Automatic liner Bottle Rinser Made In China Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords