JPN-5000 Automatic Piston Filling Machine Made In China Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ⅰ、Introduction

1.1 The machine adopts PLC and touch screen automation control, with accurate measurement, advanced structure, smooth operation, low noise, large adjustment range, the filling speed, etc. .

1.2 The delicate servo system precisely control the filling amount with precise piston stoke provides high filling accuracy, intelligent piston is designed with miner adjusting mechanism enable users to adhesive ultimate higher accuracy.

1.3 the application of touch-screen technology, the operation of the machine is more reliable, convenient and human-machine interface more friendly. Photoelectric sensors, proximity switches, etc. are used in advanced sensing elements, so no bottle no filling, plugging bottles will automatically stop and alarm.

1.4 filling way with dive style, using different materials seal rings, to meet the different characteristics of the filling material.

1.5 the machine produced according to GMP standards , all piping connections using quick way to disassemble and clean convenient location and contact with the material exposed parts are made of high quality stainless steel , machine safety, environmental protection , health, beauty, able to adapt a variety of work in different environments.

1.6 This filling machine is widely used for food, pharmaceutical, chemical, cosmetics and various industries.

Ⅱ、Feature

2.1 Controlled by Panasonic servo system.

2.2 Controllable and various filling speed.

2.3 Integrated digital control with MITSUBISHI PLC and Touch Screen controls

2.4 Designed for easy change-over and cleaning.

2.5 GMP standard Stainless Steel.

2.6 No bottle-no fill system.

2.7 Quick change of volume with digital readout.

2.8 Individual piston adjustment for fine tuning.

2.9 Adjustable speed while filling, it can fill slowly at the beginning and then accelerate to faster speed, finally slow down once again to finish up. This can prevent foamy liquids from bubbling and avoid spillage.

Ⅳ、Specifications:

4.1 Filling Capacity:500cc-5000cc

4.2 Model :JPF-4A/6A/8A

4.3 Filling Heads :4/6/8

4.4 Filling error:±0.5%

4.5 Power:2.5kw

4.6 Speed:≤2000B/H

4.7 Air source: 0.6Mpa——0.8Mpa clean and stable air source

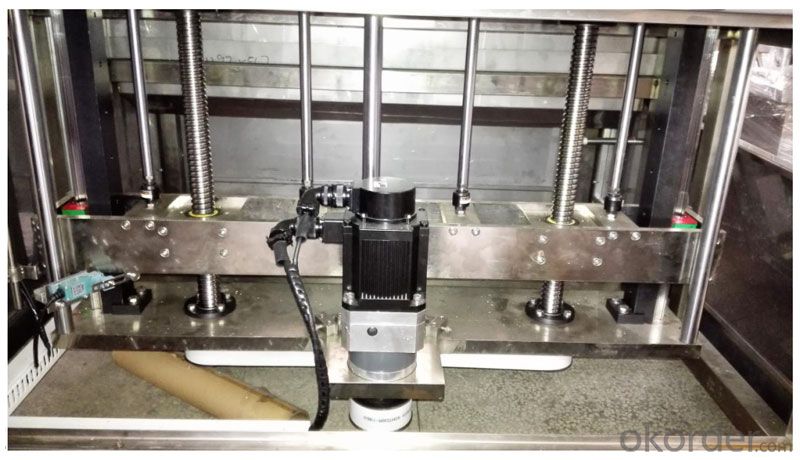

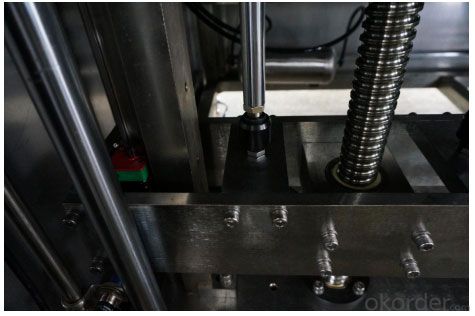

Ⅴ、Images

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q: What packing materials should be understood in purchasing?

- Other specific products, specific problems specific analysis, because the product form is not the same, liquid or chemical products packaging is not the same, the general small commodities, daily necessities of packaging almost the same

- Q: Billycan what are the advantages compared with other packaging materials?

- Shapes: tinplate cans can be made into various shapes according to different needs, such as cans, cans, cans, circular elliptical horseshoe and trapezoid etc, can satisfy the different needs of product packaging, and the packaging container more change, promote sales.

- Q: What are the characteristics of paper holders in comparison with other packaging materials?

- The first is the protection of the environment, paper packaging raw material is waste paper pulp, not only has no pollution to the environment, but also conducive to conserve resources, protect the environment. The use range of paper tray is very extensive, with the improvement of technology paper,

- Q: What advantage does PET material have in packing?

- As a packaging material, PET has good mechanical properties, and its impact strength is 3~5 times of that of other films. It has good folding resistance

- Q: What's the packing bag for rice and noodles?

- Snakeskin bag is PP (polypropylene) prepared under the high temperature, the decomposition of toxic substances, toxic substances without the plastic products, plastic products reached 65 degrees in temperature, toxic substances will precipitate and penetrate into the food, it will cause harm to the important parts of liver and kidney, reproductive system and central nervous system in human.

- Q: What material is the vacuum packing bag, please?

- Vacuum packaging is a general term for flexible packaging composite membrane products. If the temperature is different, there will be a lot of division: there is less than 100 bactericidal, and some need 100 degrees of sterilization, and 121 degrees and 135 degrees. Of course, there is also room temperature, the choice of this temperature under the condition of the sterilization method is irradiation sterilization. And also consider the content and weight of the package to determine the reasonable use of the packaging materials. There is no static, and the right is the best.

- Q: What kind of fruit package do you have?

- Fruit packaging, pet plastic fruit packing box, PET material, environmental protection non-toxic, not only moisture-proof, the product is also transparent, beautiful, smooth, light weight. And there are air holes, to ensure the flow of air, but also affixed labels, indicating fruit information, so that customers at a glance.

- Q: What material or paper should I use for high-grade packaging?!

- Coated art paper or special paperMDF or industrial paperboardI provide the classic blue sky blue the Yanghe River Daqu wine with glue

- Q: What's the difference between a package and a package?

- Packaging materials are used in the manufacture of packaging containers, packaging, packaging and printing, packaging and transportation to meet the packaging requirements the use of materials, which include the main packaging materials, metal plastic, glass, ceramics, paper, Takemoto, wild mushroom, natural fiber, chemical fiber, composite materials, coatings, adhesives and, banding, decoration, printing materials and other auxiliary materials.

- Q: Is the antistatic value of PS material (or other packing material) as small as possible?

- PS materials need special antistatic agent, Wuxi giant plasticized material has an antistatic agent, good, can be used in ABS, GPPS, HIPS, PPS, EPS and so on, the effect is good.

Send your message to us

JPN-5000 Automatic Piston Filling Machine Made In China Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords