JLP-120 Automatic Bottle Unscrambler Made In China Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Product ShortDesc:

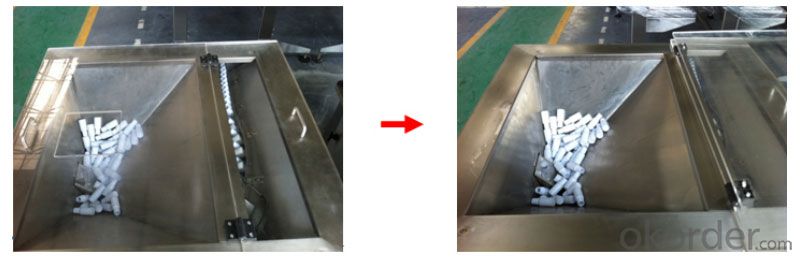

JLP-120 Automatic Bottle Unscrambler is making up of the bottle holder, unscrambling plate and bottle stand. It is applied to the bottle unscrambling of plastic round and flat bottle. When putting the disordered bottle into the bottle holder, through the unscrambling plate, then the bottles will be in the filling line in order. The machine has the features of simple structure, easy operation and good stability.

2、Product Details

JLP-120 Automatic Bottle Unscrambler is making up of the bottle holder, unscrambling plate and bottle stand. It is applied to the bottle unscrambling of plastic round and flat bottle. When putting the disordered bottle into the bottle holder, through the unscrambling plate, then the bottles will be in the filling line in order. The machine has the features of simple structure, easy operation and good stability. It can reduce the labor force. It is your ideal choice for unscrambling the small bottles.

3、Features

3.1 Bottle Holder

3.2 Bottle Unscrambling Structure

Simple structure and easy operation

3.3 Automatic Control

Complete control function, easy operation. It uses frequency converter to control the bottle unscrambling speed.

3.4 Automatic Coordination Function

The machine has the automatic coordination function. When the sensor checks the jam before the filling machine ,the bottle unscrambler will stop. After the jam problem solves, it will restart working.

4、Main Technology Parameter

4.1 Applicable Bottle Size:10-200ml Round, Flat Bottle

4.2 Bottle Diameter:Ø20-40mm

4.3 Capacity:≤120 bottles/hour

4.4 Power:0.5Kw

4.5 Power Source:220V 50Hz

4.6 Amount of Air-consuming : 0.3m³/min

4.7 Weight:350㎏

4.8 External Dimension:900×900×1200(mm)

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q: What is the charge for packing materials?

- Included in the purchase of goods purchased by the cost, such as material in transit, fixed assets, raw materials and so on, but in the material to the buyer designated place, because the buyer's own reasons again the transport costs included in administrative expenses.

- Q: Paper bags, milk and plastic bags. What's the difference between milk and paper bags?

- Plastic bags - aseptic plastic bags are specially treated with a black coating inside the plastic bag, which serves as a barrier to light. However, due to the relatively thin plastic bags, even after special treatment, the effect of isolation of light can not be compared with aluminum foil, so the normal temperature guarantee period of milk is about 30 days.

- Q: What are the packing materials for heavy cargo transportation?

- Common transport packaging materials are: lining board, foam plastic, air cushion film, air cushion film, other fillers and so on.

- Q: What are biodegradable packaging materials?

- Biodegradable packaging has a bright future and has attracted worldwide attention. In this paper, the properties, degradation mechanism, processing technology and application of various kinds of degradable packaging materials are reviewed. According to the mechanism of degradation, it can be divided into biodegradable plastics, biodegradable plastics, light / biological double degradable plastics and water degradation plastics.

- Q: What are the common material choices, printing options and common sense?

- Moon high-end gift box: the use of 157G coated paper laminating grey board or board, can also be wove paper or other special craft paper.Printing: more 4C+0 printing, can be printed spot color (special gold or silver).After the process: light glue, matte plastic, local UV, matte, hot embossing, platinum (metallic film with gold, silver, blue and other colors for choice) or anti-counterfeit film (so that others can not copy), box mounted silk cloth, sponge or foam flocking plastic etc. material. Most of the handicraft is made by hand, and the materials should be chosen according to the needs and grades of the products. It has the artistic taste of elegant and elegant appearance.

- Q: What is accessory material? What is the difference between it and raw material?

- Auxiliary materials are indirect materials used in manufacturing and in manufacturing, but not the main products of the product.

- Q: What are the sales packing materials?

- Packaging in the main plastic bags and corrugated box packaging, corrugated boxes are mainly FOL, TUCK, TOP, BOX and so on; (three) the outer packing is generally used in export cartons, 5 corrugated boxes, corrugated mainly B/C watts. The outer box price calculation formula is: (long + width +8) /100 x (width + high +6) /100 X per square unit price. The length, width and height of the units are CM. For example, the size of an outer box is 60 X, 30 X, 40 CM, and the price is (60+30+8) /100, X (30+40+6), /100, X 6 (market price) = 4.47 yuan.

- Q: How many kinds of packing are there?

- According to packaging products, materials are: paper products packaging, plastic packaging, metal packaging, bamboo and wooden packaging, glass container packaging and composite materials packaging;

- Q: Does the desiccant belong to the packing material?

- Many used desiccant is involved in metal industry, some equipment and parts in the transport process, to prevent corrosion, reduce the humidity inside the packaging, the possibility of reducing dew temperature, the general formula is the packaging materials used.

- Q: Is the antistatic value of PS material (or other packing material) as small as possible?

- PS materials need special antistatic agent, Wuxi giant plasticized material has an antistatic agent, good, can be used in ABS, GPPS, HIPS, PPS, EPS and so on, the effect is good.

Send your message to us

JLP-120 Automatic Bottle Unscrambler Made In China Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords