JH-850full-automatic Horizontal hydraulic waste paper baler machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

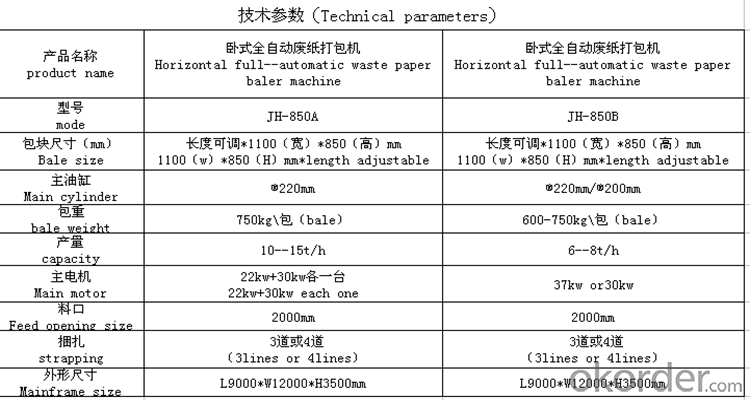

Specification

The waste paper baler machine is used for extruding and forming the waste paper and the similar products in the normal condition,and use the special packing belt bale forming ,make its volume greatly reduced,so as to cchieve the purpose of reducing the volume of transport,saving freight and increasing the efficiency of the enterprise . introducing advanced technology of similar products at home dad abroad.

Main Features

1、 PLC control ,human computer intenface and window monitoring ,sync action indication with error warning ,can set the length of the bale .

2、 Floating gate design,is conducive to the automatic distribution of all the ptessure

3、 Feed opening with distributed shear,cutting efficiency is high

4、 Automatic strapping improve pacing speed

Name: Electric machinery

Brand: jie hao

Original: china

The steel frame has high strength, light weight, and upper two-way oil cylinder. It needs no foundation, no local conditions, and easy to use.

Name: Fixed pressure package

Brand: jie hao

Original: china

Fixed pressure package length: high strength train rail joint structure; and timer control package length.

Name: system

Brand: Siemens

Original: Germany

1、The device has alarm indicator, fault display and prompt function

2、Cooling tower cooling system is adopted so that the equipment can maintain normal operation below 60° for a long period of time;

3、Lubrication system: automatic lubrication system reduces mechanical wear, reduces mechanical noise, and stabilizes mechanical operation.

1、Stranding mechanism: gear transmission, hydraulic winding; shred.

1、Stranding mechanism: gear transmission, hydraulic winding; shred.

2、Wire tie method: hydraulic hook line, trimming system, and 3 lines.

3、Bottom structure: roller track, track with wear-resistant high-quality steel 20mm. Bottom support ribs 180 GB channel.

4、Pushing system: roller device, reducing the mechanical resistance of the main hydraulic cylinder return movement, effectively increasing the speed of pushing the package. The composition of the pusher head is welded from 20mm pure steel plate with a rib thickness of 20mm.

5、Fixed pressure package length: high strength train rail joint structure; and timer control package length.

6、Lubrication system: automatic lubrication system reduces mechanical wear, reduces mechanical noise, and stabilizes mechanical operation.

Our Service

Pre-Sales Service

1.Your inquiry will be replied within 24 hours.

2.Any questions, you could email us or call directly.

3.24 hours technical support by e-mail.

After-Sales Service

One year guarantee period after installation.

During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, we will provide them at cost price.

- Q: Where is secondhand corrugated paper packaging machinery available?

- Carton factory and general production enterprise is different,General business is to face direct consumers, the need for their own sales network, sales staff, sales means......And carton factory as long as accurate manufacturers, show their means, get business.Maybe you walked into a food factory, an electrical factory, a furniture factory, a toy factory...... Can be your client.With business, but also to choose their own plant.Cartons are flammable and afraid of water. This is the disadvantage of cartons. If handled properly, there will be no problem.Site is best to avoid low-lying and rainy lots of water, the cardboard should not be piled directly on the ground, the bracket is a good choice.No smoking in the factory area, no open fire, and good fire fighting equipment, so as to ensure the safety of production.The size of the initial plant is best to be 500 square meters, or larger, smaller.

- Q: The role of food packaging machinery

- (8) can promote the development of packaging machinery related industry is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, the overall performance of any discipline problems will affect the packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.Fig. 3 is a flow chart of liquid filling. With empty bottles of boxes stacked on pallets, by the conveyor belt to depalletizers, will remove the tray one by one, the box with the conveyor belt to the machine, remove the empty bottles from the box, empty by the conveying belt to the washing machine, after cleaning, and transported to the packing machine next to filled with beverage bottles into them. The empty bottles removed from the unloading machine are sent into the bottle washing machine by another conveyor belt for disinfection and cleaning. They are tested by the bottle inspection machine and conform to the cleaning standard and then enter the filling machine and capping machine. The beverage is bottled from a filling machine. Packed beverage bottle capping machine with the sealed and transported to the labeling machine labeling, (see pictures) with various beverage bottle filling line of the process is similar. But because of the different nature of beverage, the filling machine and capping machine are also different.

- Q: What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q: What are the main functions of packaging machinery and equipment?

- Packaging machinery can be realized in the packaging process, including filling and wrapping,

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packing machine? Should the packing of the tableware be contracted? Tak Cheung packing machinery, automatic heat shrinkable tableware packing machine can be considered

- Q: What is the delay time of the packer's cross sealing?

- There is also a delay in the end of the last movement of the machine to the beginning of the sealing action.

- Q: How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- Urea formaldehyde resin is a water-soluble resin, easily cured, the cured resin colorless, non-toxic, good light resistance, long-term use does not change color, heat molding will not change color, can add various colorants to prepare various brightly colored products.Urea formaldehyde resin is hard, scratch resistant, weak acid, weak base and grease. It is cheap and has certain toughness, but it is easy to absorb water, so it has poor water resistance and electrical properties, and its heat resistance is not highThe use of urea formaldehyde resin is widely used in plastic, mold, laminated plastic, foam, also can be used for the production of water-soluble adhesive, the adhesive for wood; fabric shrinkproof and crepe treatment agent; used as a varnish of paper, in order to improve the wet strength of paper. The following is a simple Shaoxing on it the application of the plastic.

- Q: What are the structures of the packaging machinery?

- Is far from a professional engaged in "packaging machinery" research and development, production, sales as one of the multinational enterprise groups. It is the largest manufacturer of packaging machinery in china. Located in the Chinese science and Education City - Hefei, the geographical position is superior, the traffic condition is convenient, and the sale network extends the whole country. Is far from, with a group of the world's top machinery manufacturing R & D team, specializing in all walks of life packaging enterprises, for the efficient production of enterprises to provide power. It is a large enterprise that put forward the concept of packaging automation earlier in china. Brand with strong economic strength, first-class R & D level, advanced business philosophy and good brand service, more and more people all over the world are respected and trusted. The entire manufacturing process in full accordance with the highest standards of global manufacturing; at the same time according to the quality standard of global market development process, operating procedures and quality control system of production, all is "far Machinery" have reached world-class standards. "Far distance machinery" combines the characteristics of all kinds of products in China, such as packaging machinery, food packaging machines, two times packaging machines, powder packaging machines, particle packaging machines, liquid packaging machines, weighing machines, and so on. It is well received by Chinese enterprises!

- Q: What does the mechanical equipment include?

- Hydraulic lifting track machineHydraulic tamping machine, rail sawing machine, rail machine

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard specifies the terms and definitions, models, types and basic parameters, technical requirements, test methods, inspection rules and signs, packaging, transportation and storage requirements of the three-dimensional packaging machine for transparent film.

Send your message to us

JH-850full-automatic Horizontal hydraulic waste paper baler machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords