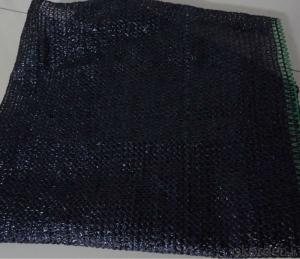

ISO Standard PE Tarpaulin for Waterproof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PE Tarpaulin

Company and Product Introduction

Our company was founded in 1984, with production area more than 100000m2, more than 300 production lines, including 10 sets drawing machine, 250sets woven machine, 20 sets coating machine, 20 printing machine.

We specializing in producing and exporting tarpaulin, including PE tarpaulin, PP tarpaulin, PVC tarpaulin, Mesh tarpaulin, Camouflage tarpaulin, and special customized tarpaulin.

Feature of Tarpaulin

-Waterproof

-Sun block

-Freezing-resistant

-Anti-aging

-corrosion-resistant

-Portable, easy folding and durable

Application of Tarpaulin

-Make shock proof shed

-Greenhouse

-Woven bag

-Grass prevention cloth

-Furniture cover

-Insulation quilt

-Truck cover

-Also widely used in shipyard, oil field, industrial and mining area, petroleum industrial, construction site, etc.

Tarpaulin technical data

Material | HDPE woven fabric with LDPE coating in both sides |

Density | 6*6~16*16 mesh |

Weight | From 50g/m2 up to 300g/m2 |

Color | Blue/ Grey/ Green/ White/ Yellow/ Red, any color is avalible |

As customer required | |

Tarpaulin Roll Size | 100m per roll or as customers’ requirement |

Tarpaulin Sheet Size | Regular size(m*m): 2*3, 3*4, 3*5, 4*5, 4*6, 5*8,6*8,6*10,10*50, or as customers’ requirement |

Package | 1.Tarpaulin roll is packed on paper coil, packed by tarpaulin same with inner products. 2.Tarpaulin sheets are packed in a bale every 5sheets or as customers’ requirement. Carton packing is also available. |

Container Loading | 1. Tarpaulin rolls: 20GP can load 17 tons. 2. Tarpaulin sheets in bale packing: 20GP can load 10ton, 40HQ can load 25 tons. 3. Carton packing: 20GP can load 8 tons, 40HQ can load 22 tons. |

FAQ:.

1. What’s the payment term?

TT: 50% before production, 50% before shipment.

Or LC at sight.

2. Can you provide free samples?

Yes, we support you with free of charge samples, you’ll just need to pay for the express cost.

3. What’s your leading time?

For regular items, 2~3 days will finish one 40HQ. For special items, 7~15days will finish one 40HQ.

4. Will you support factory inspection and products inspection before shipment?

Yes, warmly welcome you to visit our factory and inspect products quality before shipment.

- Q: How do automotive plastic products contribute to sustainability?

- Automotive plastic products contribute to sustainability in several ways. Firstly, they help reduce the weight of vehicles, leading to improved fuel efficiency and lower emissions. Plastic components are lighter than their metal counterparts, resulting in reduced energy consumption during manufacturing and improved overall vehicle efficiency. Secondly, plastics are highly recyclable materials, allowing for the reuse of automotive plastic products in various applications. This reduces waste and conserves resources. Additionally, plastic parts are often more durable and resistant to corrosion, extending the lifespan of vehicles and reducing the need for replacements. Overall, automotive plastic products play a significant role in promoting sustainability by enhancing fuel efficiency, enabling recycling, and prolonging the life of vehicles.

- Q: Can a motorcycle use a plastic tank?

- It seems I haven't seen a plastic fuel tank yet! I didn't see any of the two cars upstairs. They were made of plastic. They just looked like they were plastic, but they weren't plastic. You can tear it apart if you don't believe it.

- Q: Can automotive plastic products be used in suspension and steering systems?

- Yes, automotive plastic products can be used in suspension and steering systems. They are commonly used in components such as bushings, control arms, and steering racks due to their lightweight, durability, and cost-effectiveness. Plastic materials can provide the necessary strength, flexibility, and resistance to vibrations and impacts required for these critical systems in vehicles.

- Q: How do automotive plastic products contribute to improved resistance to oil and fuel?

- Automotive plastic products contribute to improved resistance to oil and fuel due to their inherent properties and design considerations. These products are typically made from high-quality, chemical-resistant plastics such as polypropylene or polyethylene, which have excellent resistance to oil and fuel. Additionally, manufacturers often incorporate additives and reinforcements into the plastic, such as glass fibers or special fillers, to enhance its resistance to these substances. Moreover, automotive plastic products are designed to have tight seals and gaskets, preventing oil and fuel from leaking or seeping into sensitive components, thereby enhancing overall resistance.

- Q: Are there any disadvantages to using plastic in automotive products?

- Yes, there are several disadvantages to using plastic in automotive products. Firstly, plastic is not as durable or strong as metal, making it more susceptible to damage in accidents or collisions. Additionally, plastic can degrade over time due to exposure to sunlight, heat, and other environmental factors, leading to a decrease in its structural integrity. Moreover, plastic is not as heat-resistant as metal, which can pose a risk in high-temperature situations like engine compartments. Finally, plastic components can be more challenging and costly to repair or replace compared to metal ones.

- Q: Can automotive plastic products be painted or coated?

- Yes, automotive plastic products can be painted or coated.

- Q: Are automotive plastic products resistant to engine oil?

- Yes, automotive plastic products are typically designed to be resistant to engine oil.

- Q: What are some examples of automotive plastic products used in seat belts and restraints?

- Some examples of automotive plastic products used in seat belts and restraints include plastic buckles, fasteners, adjusters, and guides.

- Q: What are the potential health risks associated with using plastic in automotive products?

- The potential health risks associated with using plastic in automotive products include exposure to harmful chemicals, such as phthalates and bisphenol A (BPA), which are known to be endocrine disruptors. These chemicals can leach out of the plastic over time, especially when exposed to heat or UV radiation, and may have adverse effects on human health, including hormone imbalances, reproductive issues, and increased risk of certain cancers. Additionally, the production and disposal of plastic can contribute to environmental pollution and ecosystem disruption, further impacting human health indirectly.

- Q: How do automotive plastic products contribute to recycling and sustainability efforts?

- Automotive plastic products contribute to recycling and sustainability efforts in several ways. Firstly, the use of lightweight plastic materials in vehicles helps to improve fuel efficiency, reducing greenhouse gas emissions and promoting environmental sustainability. Additionally, many automotive plastic components are designed to be easily recyclable, allowing for the recovery and reuse of these materials at the end of their lifespan. This promotes circularity and reduces the need for virgin plastic production. Moreover, the durability and longevity of plastic parts in automobiles reduce the frequency of replacements, further reducing waste generation and resource consumption. Overall, automotive plastic products play a crucial role in promoting recycling and sustainability in the automotive industry.

Send your message to us

ISO Standard PE Tarpaulin for Waterproof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords