ISO-9001 2008 Ductile Iron Casting Manhole Cover for Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 kg

- Supply Capability:

- 4300 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

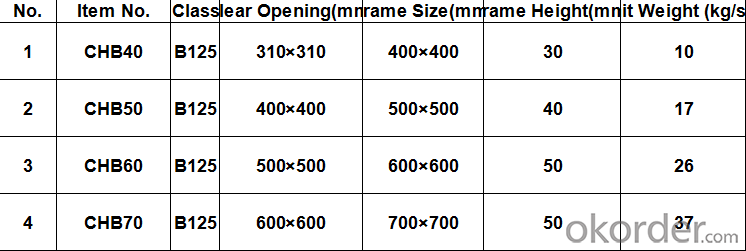

Specification

Product Description

1) Designs: based on EN124 standard and according to customer's drawing or

samples.

2) Applications: water supply and drainage, fire engineering, natural

3) Inspection: in-house or the third party as per customer's request.

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than.

Contain no metal and no recovery value, anti-theft.

Company Information

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard

Specifications

Double triangle ductile iron manhole cover

1.Standard:ISO 9001 EN124 D400

2.Service:OEM

3.High quality

4.Made of ductile

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press.Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

5. Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

6. Professional technical support with free charge.

7. After the cooperation: Any of your problem will be solved within 24 hours.

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- The material is usually steel material price plus the cost (per ton of 2.5-3 million, plus profit).In the Yangtze River Delta region, generally 304 casting price of about 5-5.5 million / ton.The price will be higher if the parts are complex, or a piece weighs less than 100 grams.

- Q: Why does the precision casting factory not usually make iron castings?

- Because it is too cheap, the design of materials is cast iron, generally do not have very high requirements.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Especially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- The clay wet sand castings casting weight from a few kilograms until tens of kilograms, but the clay dry type of casting production can be weighed dozens of tons.For medium and large castings, cast iron, cast steel can be self hardening sand with resin can be water glass sand production, can obtain the precise size, smooth surface castings, but casting precision, surface roughness, density and microstructure, mechanical properties and material cost of sand casting production is often poor, so when the higher performance requirements of castings, should adopt other casting methods, such as casting (lost wax casting), die casting, low pressure casting.

- Q: What are the causes of pitting on the surface of a precision casting?

- The quality of the shell surface is out of order. Or shot blasting out of question.

- Q: How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- The general foundry casting technology division will mark put shrinkage and the allowance of the map in your chart (usually with the red pen) for the production of wood or other material wood workers die drawings.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

Send your message to us

ISO-9001 2008 Ductile Iron Casting Manhole Cover for Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 kg

- Supply Capability:

- 4300 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches